TECHNICAL SERVICE MANUAL FOR KEMPOWELD

TROUBLESHOOTING CHART

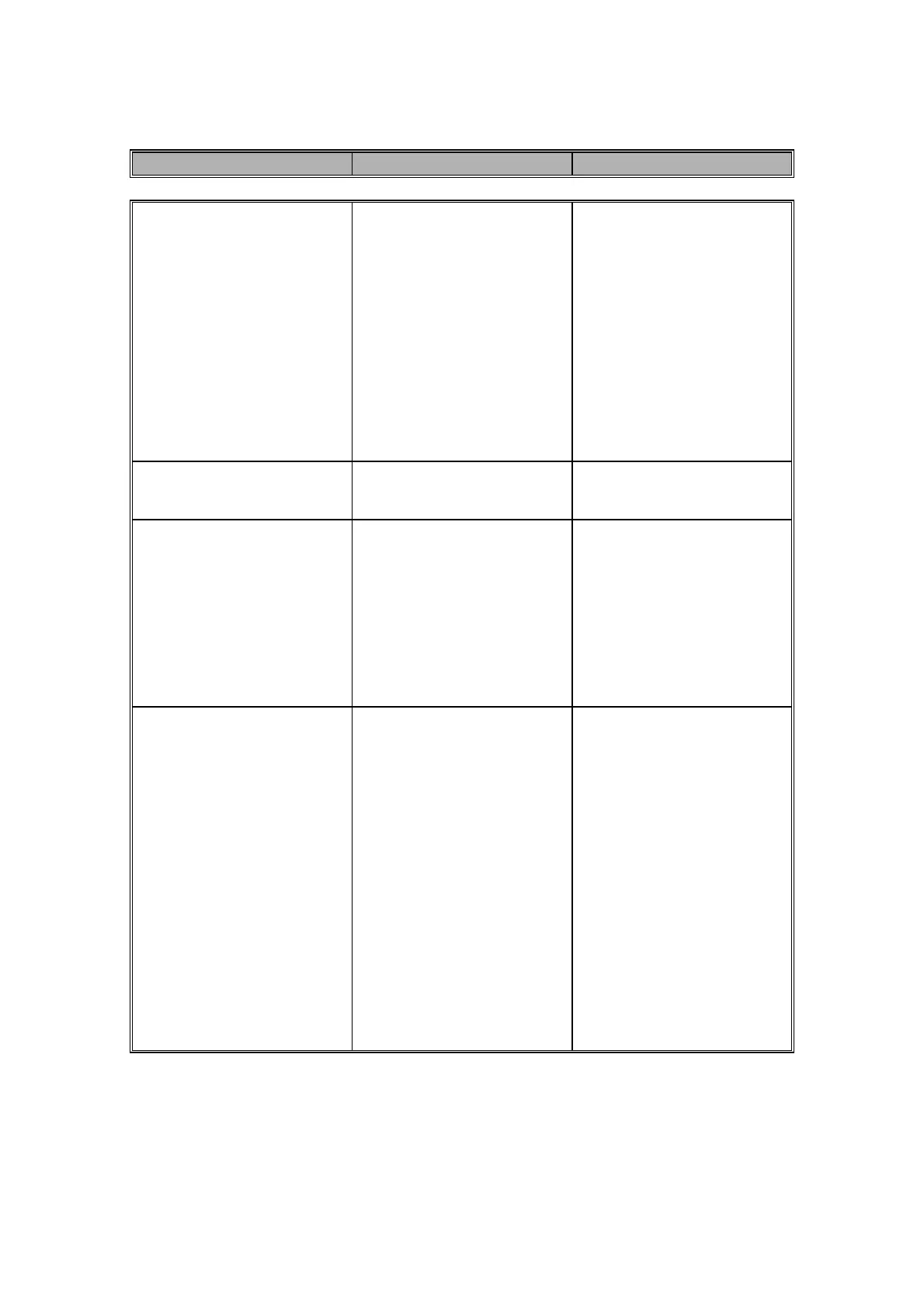

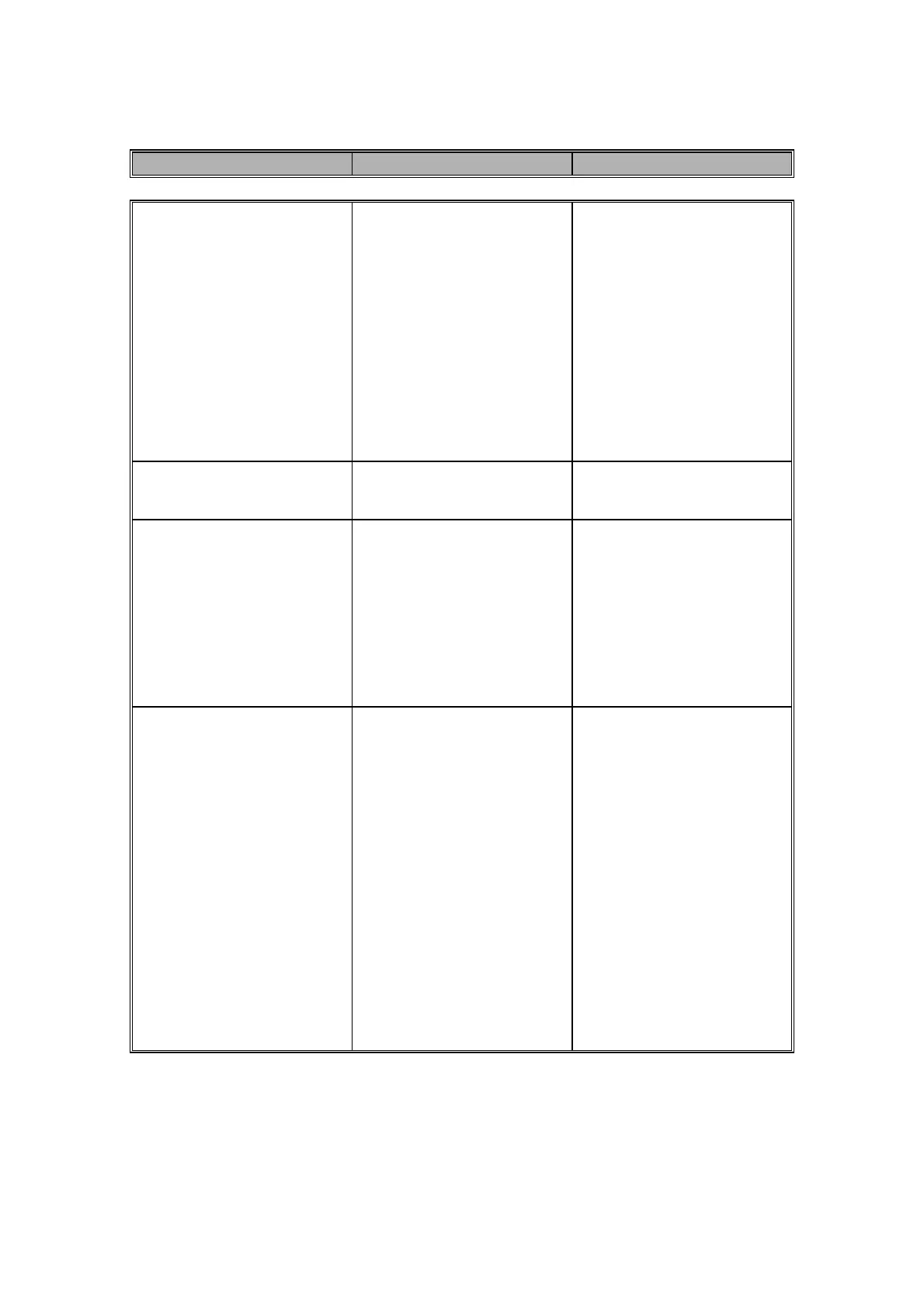

TROUBLE CAUSE REMEDY

The cooling unit don´t start or pilot

lamp Hw3 lacking water pressure is

iluminated.

Blown fuse F002 2A.

Auxiliary transformer T002.

Pressure switch S005

5µF capacitor C001.

Broken PCB.

Check and change the fuse if

needed.

Check the voltage from transformer

in the terminal block between 2.1

and 2.2, it should be 230v.

Check the voltage over the pressure

guard or from PCB A002 X2/1 and

X2/8; enough pressure 0V and lack

of pressure c. 5V.

Check and change the capacitor if

needed.

See, TROUBLE SHOOTING FOR

PCBs appendix 1.

The solenoid valve Y001 don´t work. Faulty solenoid valve or PCB A001. Check the 24 VDC from connector

X3/5 and X3/6, change valve or

PCB.

Wire feeding motor don´t work. Blown fuse F001 8A

The control cable between feeder

and power souce is broken or it is

not properly tightened.

Faulty motor or PCB A001in

K200/400.

Broken PCB.

Check/change the fuse if needed.

Check and repair the control cable if

needed. See table 1.

Check the motor voltage from A001

X4/12 and X4/13 max. is c. 24 VDC,

if it´s all right motor is faulty.

See, TROUBLE SHOOTING FOR

PCBs appendix 1.

Welding quality is bad:

- arc is not stable

- there are lot of spatters

- bad arc start

- not enough arc voltage

One phase is missing.

Faulty main transformer T001.

Faulty main switch S001 or contactor

K001.

Shielding gas is missing.

Gas hose of the gun is leaking or

connection is loose.

Broken diode in the secondary.

rectifier G001.

Check all phases from the therminal

block X001. Change mains fuse if

needed or tighten mains cables.

Check that voltages are symmetric

over the three spools of T001.

Variation of voltage is depending on

voltage selection and load; normally

it is between 10 VAC and 32 VAC.

OCV variation range is 11 VAC

to 35 VAC

Measure first main switch if it is all

right check the contactor.

Check the valve according the

instructions mentioned above.

Check/repair the mig gun.

Check and change diode(bridge)

if needed.

Loading...

Loading...