EN

Shielding gas

The shielding gas used for steel wires is carbon dioxide or a mixture of argon

and carbon dioxide which replaces air in the arc’s area. Shielding gas for

stainless steel wires is a mixture of argon and carbon dioxide (2%) and argon

for aluminium wires. Thickness of the welded sheet and welding power

dene the ow rate of the shielding gas.

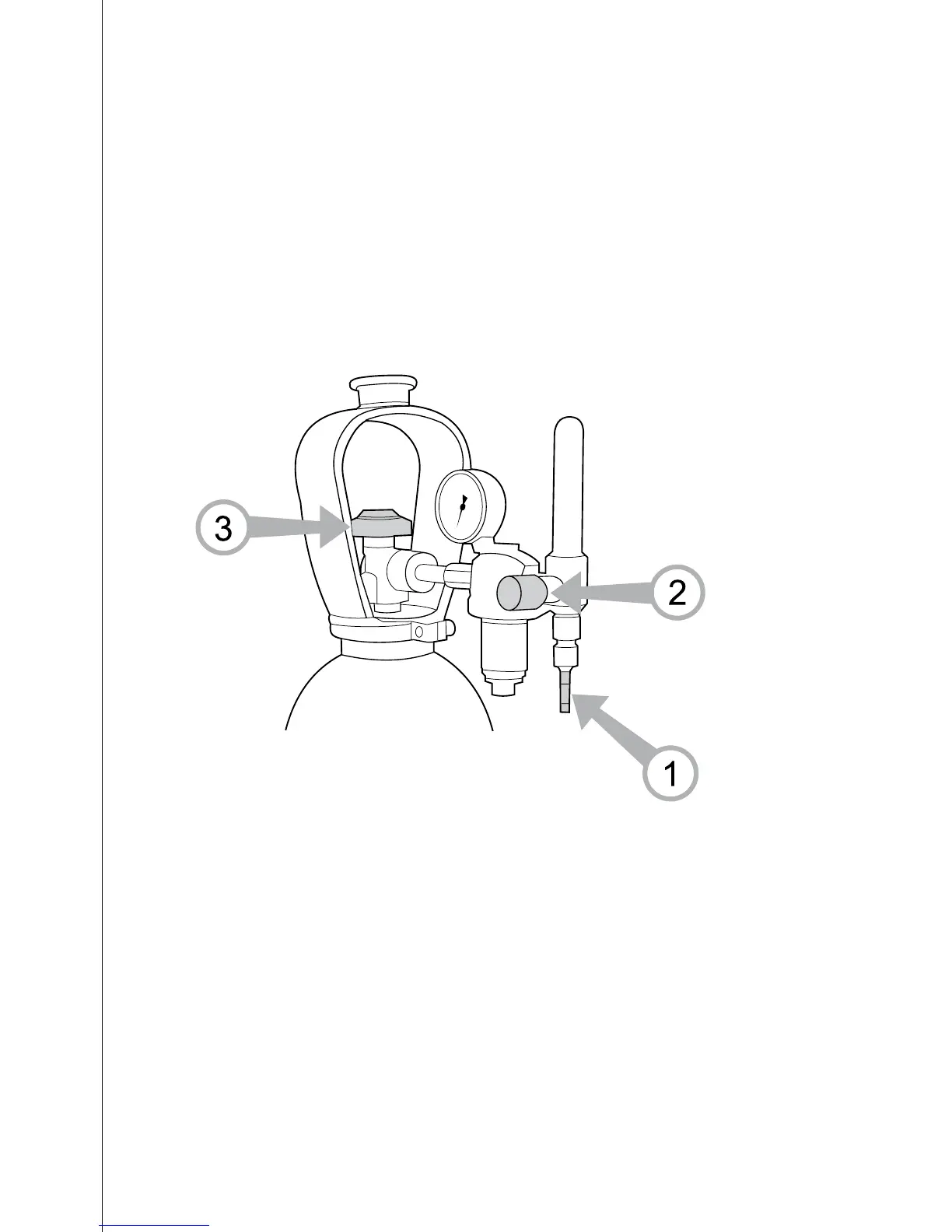

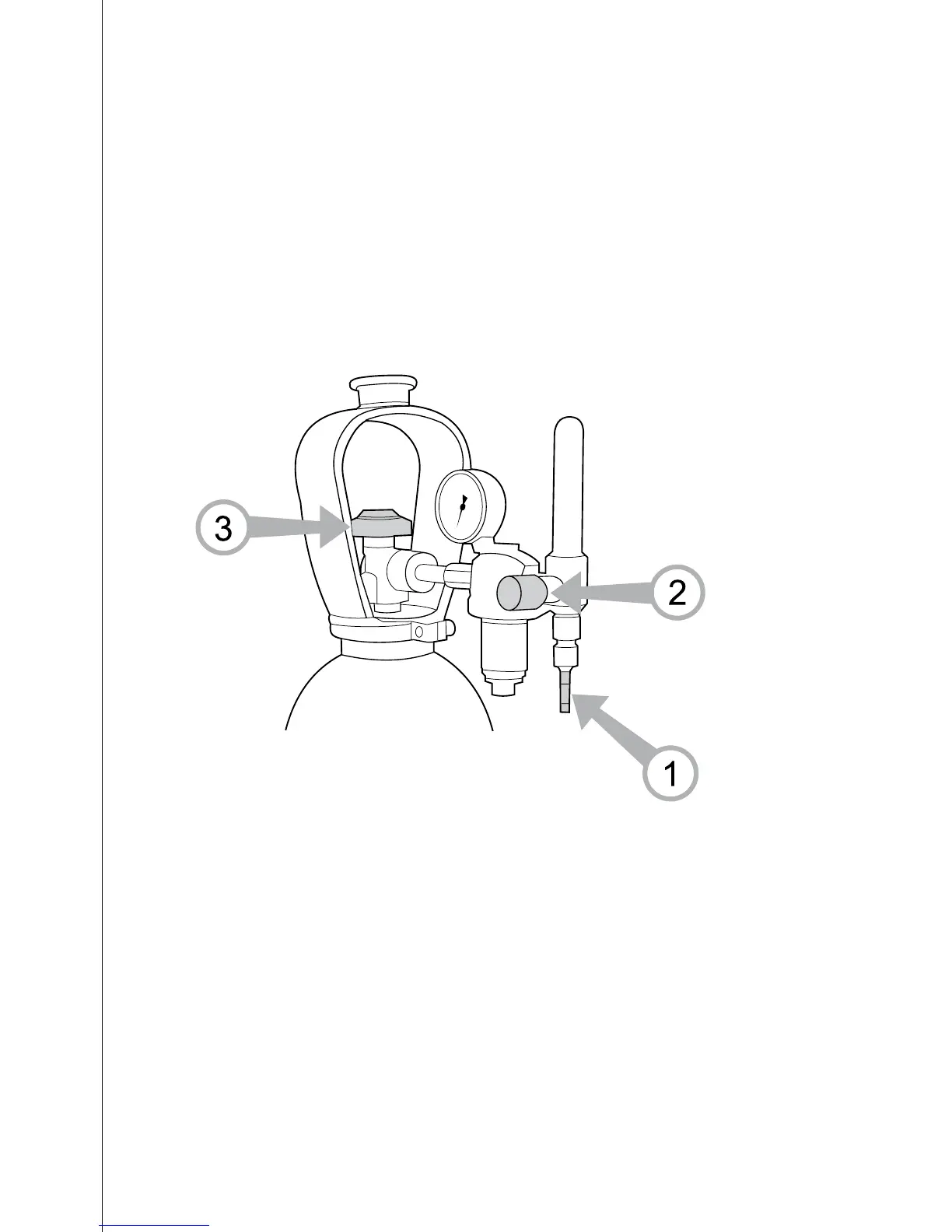

The machine is delivered with a 4.5 m long shielding gas hose. Connect the

bayonet socket of the shielding gas hose to the machine’s hose connector

and the hose connector end to the gas bottle’s control valve.

1. Connect the hose to the gas bottle’s control valve and tighten the

connector.

2. Adjust the ow rate with the control valve screw. A suitable shielding gas

ow rate is 8–15 l/min.

3. Close the bottle’s valve after use.

NOTE! Use a shielding gas suitable for the material’s welding. Fix the gas bottle

securely in an upright position before installing the control valve.

8

MinarcMig 180 / © Kemppi Oy / 1117

Loading...

Loading...