EN

weld joint. Filler wire is fed into the weld pool from the outside of the arc and gas shield. The

ller wire and the welding current level are decided according to the base material type and

thickness, joint form and welding position.

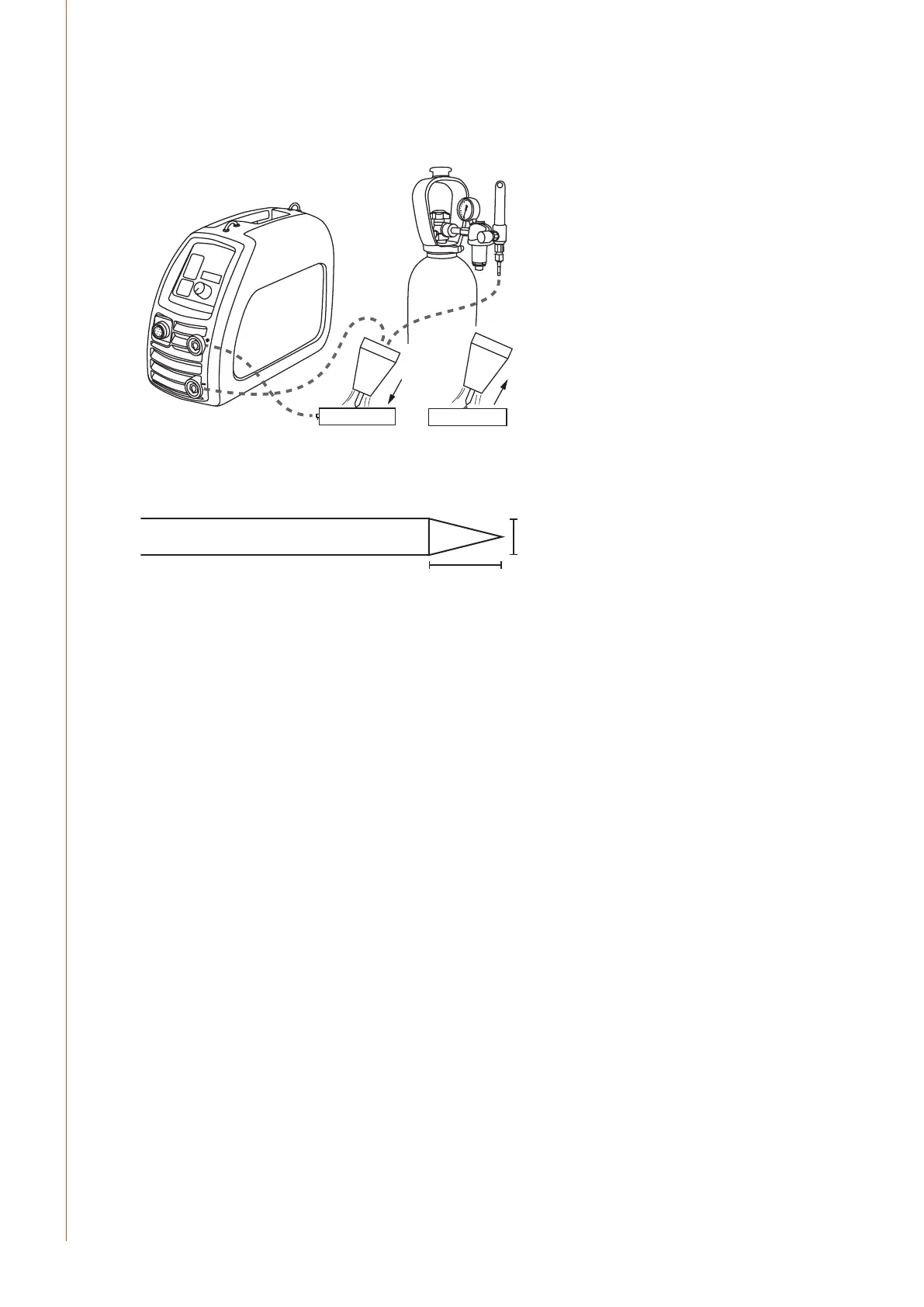

0.5 s

NOTE! Ensure you protect your eyes and face with suitable equipment.

NOTE! The tungsten electrode tip should be sharpened as described.

D

2xD

3.3.1 DC TIG welding

Select your required welding parameters according to the joint to be welded.

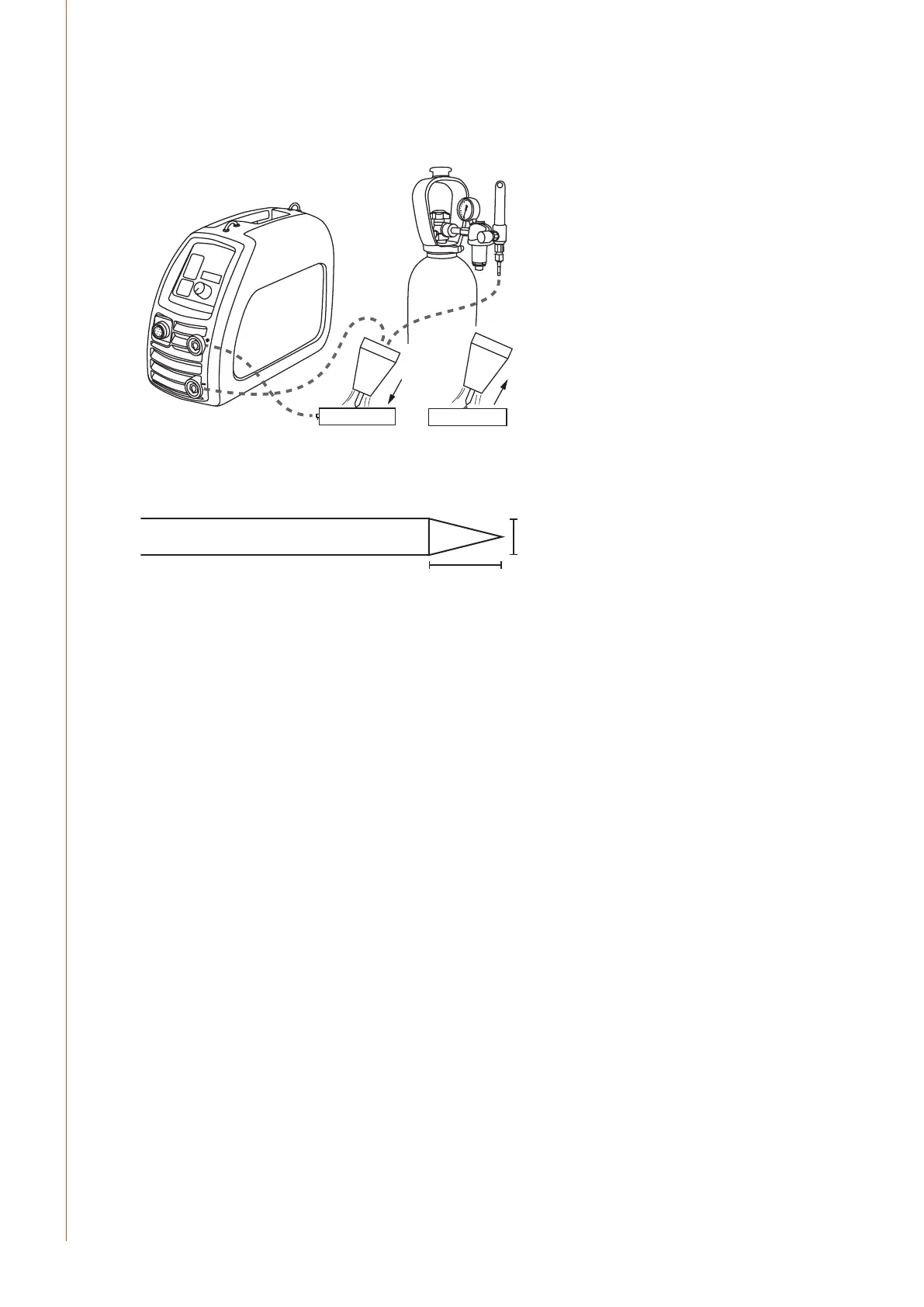

1. Connect TIG torch to the negative (–) pole of the power source, and earth cable to

positive (+) pole.

2. Select TIG welding mode by pressing the process selection button on the control panel.

3. Select a suitable welding current by adjusting the current adjustment knob.

4. Ensure your argon shielding gas supply is switched on and the ow rate is approximately

8 to 10 litres per minute.

5. Make a small test weld to check the selections made.

3.3.2 Earth return cable and clamp

If possible, always x the earth return cable and clamp directly to the work piece.

1. Clean the connection surface of earth clamp from paint, dirt and rust.

2. Connect the clamp carefully so that contact surface is as large as possible.

3. Finally check that the clamp remains fastened.

3.3.3 Tungsten inert gas welding (TIG)

Argon shielding gas is used in DC TIG welding. Your dealer will give you advice on choosing

the correct gas, supplier, and supporting equipment. Open the gas valve on the Kemppi

TTM 15V TIG torch. When the gas starts to ow, ignite the arc. The arc is activated by lightly

touching the work piece with the tungsten electrode and lifting away. A reliable technique to

practice is, lightly and briey touch the tungsten electrode to the work piece surface and then

rock backwards onto the ceramic nozzle of the TIG welding torch, so the tungsten is no longer

in contact with the work piece surface. This action makes and breaks a momentary contact of

the tungsten electrode in a controlled manner, rst making the electrical circuit and secondly

establishing the TIG welding arc the moment the tungsten leaves contact to the work piece

surface.

Minarc Evo 180

10

Loading...

Loading...