14 15

EN Choose weld shape.

DA Vælg svejsesømsform.

DE Schweißnahtform wählen.

ES Seleccione la forma del cordón de soldadura.

FI Valitse hitsin muoto.

FR Choisir le prol de la soudure.

IT Scegliere forma del cordone.

NL Kies lasvorm.

NO Velg sveisens utseende.

PL Wybierz kształt lica spoiny.

PT Escolha o formato do cordão.

RU Выберете форму шва.

SV Ställ in svetsform.

ZH 选择焊接方式。

EN Adjust welding voltage to suit application. See p19 for parameter guide.

DA Indstil lysbuespænding som passer til svejseopgaven. Se p19 for vejledende parametre.

DE Schweißspannung passend für die Anwendung einstellen. Parameterliste auf Seite 19.

ES Ajuste el voltaje de soldadura según la aplicación. Consulte la página 19 para ver la guía

de parámetros.

FI Valitse työkohteeseen sopiva hitsausjännite. Katso parametrien ohjearvot sivulla 19.

FR Ajuster la tension-soudage pourl'application. Consultez la page 19 pour les paramètres du guide.

IT Impostare tensione di saldatura idonea all'applicazione. Vedere pag. 19 per la guida dei parametri.

NL Stel het voltage in volgens de toepassing. Zie pagina 19 voor parameter gids.

NO Justér buespenning som passer til sveiseoppgaven. Se s 19 for parameter anbefalinger.

PL Dostosuj napięcie spawania do aplikacji. Parametry techniczne patrz str. 19.

PT Ajuste a voltagem conforme a aplicação. Veja p.19 para guias de parâmetros.

RU Отрегулируйте напряжение. Руководство по настройке параметров вы найдете на

странице 19.

SV Justera bågspänning. Se s 19 för parametermanual.

ZH 调节焊接电压以满足应用。参考P19调整焊接参数。

AUTOMATIC

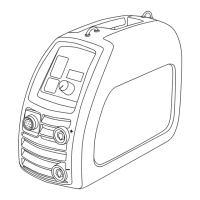

MinarcMig Evo 200

MANUAL

MinarcMig Evo 170

Loading...

Loading...