EN

10

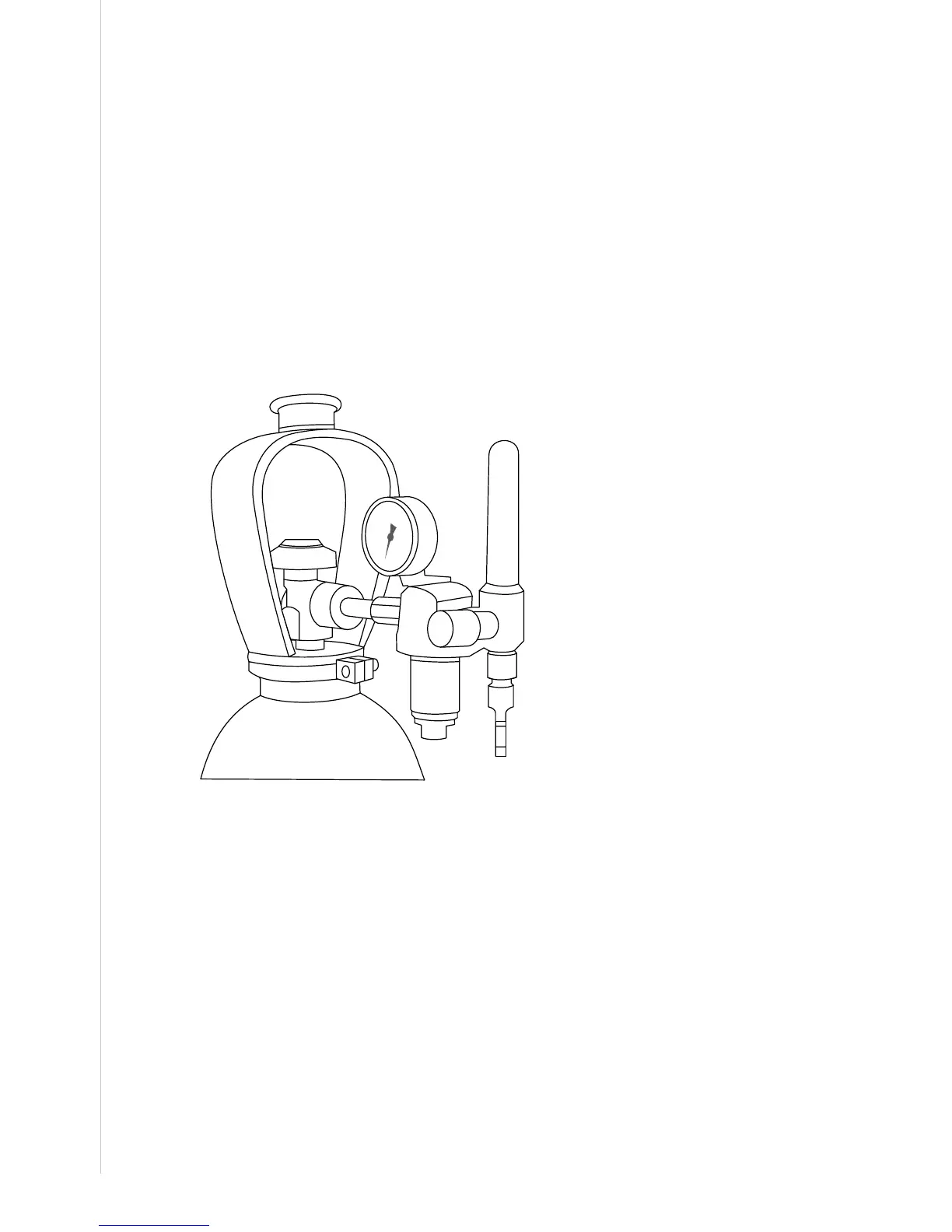

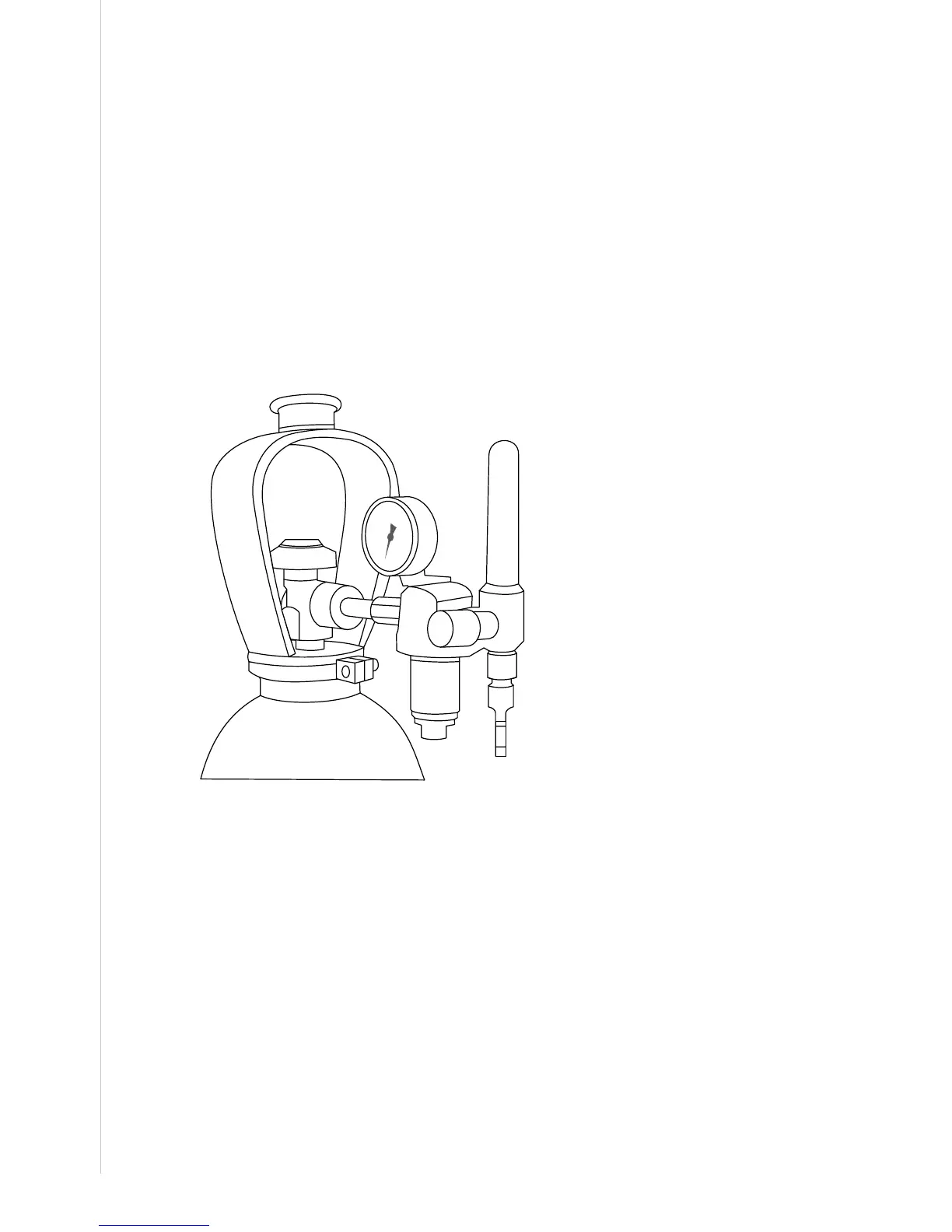

Shielding gas

In TIG welding, shielding gas is used to prevent atmospheric contamination

of the molten weld pool and cooling weld. Normally, the shielding gas

is argon (Ar). Normally the gas ow rate is approximately 8–15 litres per

minute, but this can vary according to the welding current used and the size

of gas nozzle.

The machine is delivered with a 4.5 m shielding gas hose. Connect the gas

hose snap connector to the male connector on the machine. The other end

of the gas supply hose should be connected to the outlet of the regulator.

NOTE! Under no circumstances should you connect the hose directly to

the cylinder valve. Always use a regulator and ow meter for safe and

accurate operation.

1. Connect the hose to the reduced pressure side of the cylinder

regulator, or ow meter and tighten the connector.

2. Adjust the shielding gas ow rate with the ow regulation adjustment

screw. A suitable gas ow rate is 8–15 l/min

3. Close the cylinder valve after use.

10 MinarcTig 180, 180MLP, 250, 250 MLP

Loading...

Loading...