EN

3.2 Manual metal arc welding (MMA)

In Manual Metal Arc (MMA) welding the ller material is melted from the electrode to the weld

pool. The rate of welding current is selected on the basis of the welding electrode size used

and welding position. The arc forms between the electrode tip and work piece. The melting

electrode coating forms a gas and slag shield, which protects the molten metal in transfer

to the weld pool and during solidication. As the slag solidies over the hot weld metal, it

prevents weld metal oxidation. This slag coating is removed after welding e.g. with a chipping

hammer. When removing the slag coating, ensure you protect your eyes and face with suitable

equipment.

For more info www.kemppi.com > Welding ABC.

MMA welding electrodes

In MMA welding, the welding electrodes must be connected to the correct pole. Normally,

the electrode holder is connected to the positive and the earthing cable to the negative

connector.

It is also important to properly adjust the welding current so that the ller material and

coating will melt properly and the welding is ecient. The table below presents the electrode

sizes available with the MinarcTig Evo welding machine and the corresponding welding

current values.

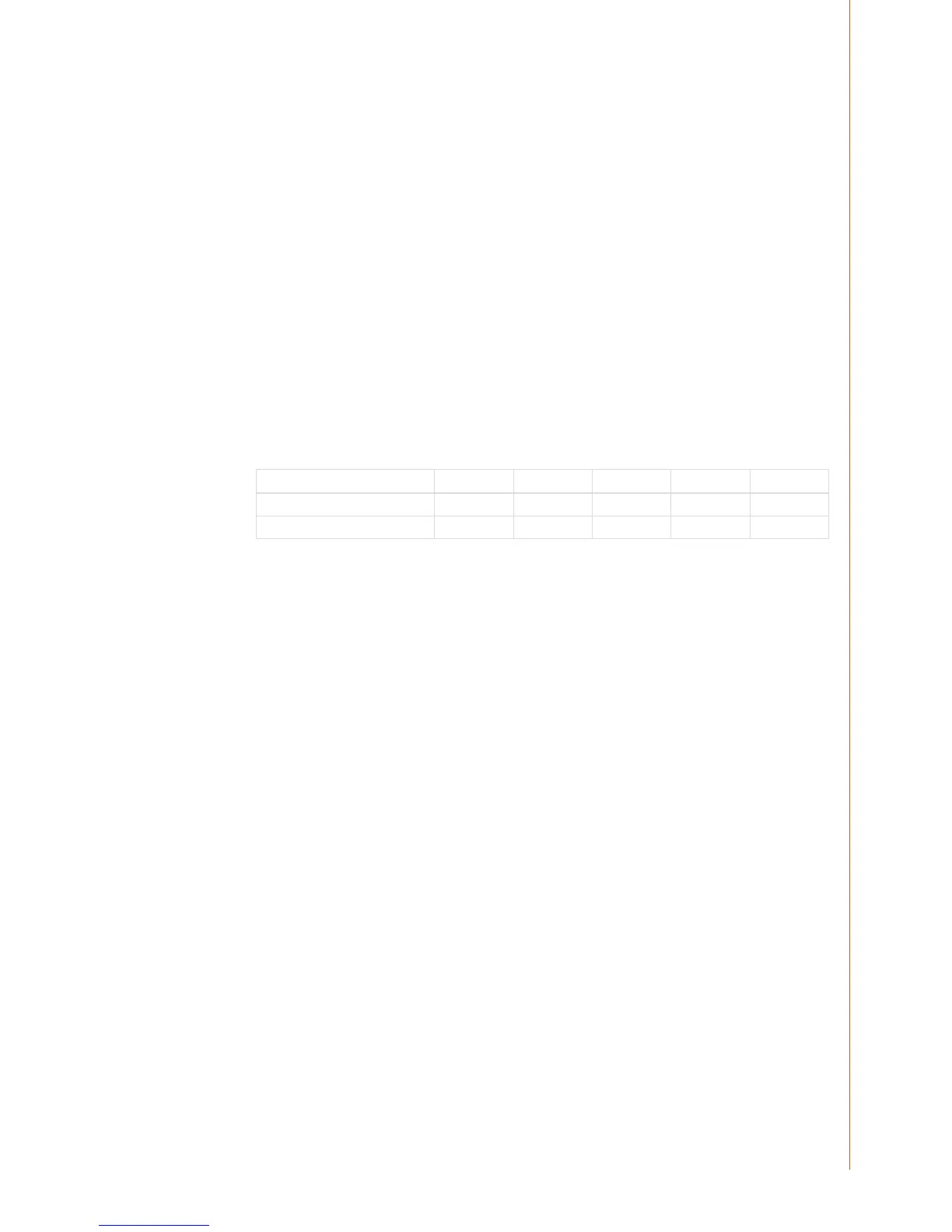

MMA Electrodes and corresponding current settings range

Electrode diameter 1.6 mm 2.0 mm 2.5 mm 3.25 mm 4.0 mm

Fe-Rutile 30–60 A 40–80 A 50–110 A 80–150 A 120–210

Fe-Basic 30–55 A 50–80 A 80–110 A 110–150 A 140–200

3.3 TIG welding

The TIG process forms an arc between the tungsten electrode and the work piece. The arc

melts the work piece forming a molten weld pool. The arc and tungsten electrode mounted in

the TIG torch, are shielded by an inert shielding gas that is connected to, and ows through,

the nozzle of the TIG torch. The gas required is Argon and the ow rate is approximately 8 to

15 litres per minute. If necessary, suitable ller material is added to the weld pool to complete

the weld joint. Filler wire is fed into the weld pool from the outside of the arc and gas shield.

The ller wire and the welding current level are decided according to the base material type

and thickness, joint form and welding position. (Gas regulator, ow meter and pure argon

shielding gas are not provided in this package.)

TIG welding electrodes and gas nozzles

In DC TIG welding we recommend the use of the WC20 (grey) type electrode, however other

types are available.

The welding electrode size (diameter) is selected depending on the welding current/power to

be used. An electrode with an insucient diameter compared to the welding current will melt,

while excessive electrode size will make it more dicult to ignite the arc.

Generally speaking, a 1.6 mm tungsten electrode will cover currents up to 150 A, and 2.4 mm

tungsten electrode up to 250 A DC current.

Before use, grind the tungsten electrode to a sharp point at approximately 1.5 times the

diameter of the electrode. If the electrode touches the work piece during welding, re-sharpen

the electrode.

7

© Kemppi Oy / 1201

Loading...

Loading...