15

© Kemppi Oy / 1736

EN

2.14 Shielding gas

NOTE! Handle shielding gas bottle with care. Assess the risks associated with handling and using

compressed gas. Always use a cylinder transport carriage and secure the cylinder safely.

There are many dierent suppliers of quality shielding gases for welding. Please ensure that

you are selecting the correct gas for your application. FastMig products use welding programs

for synergic and pulsed welding. These programs are created and recommend against a

particular shielding gas.

Shielding gas eects welding performance and is a fundamental component to overall weld

quality.

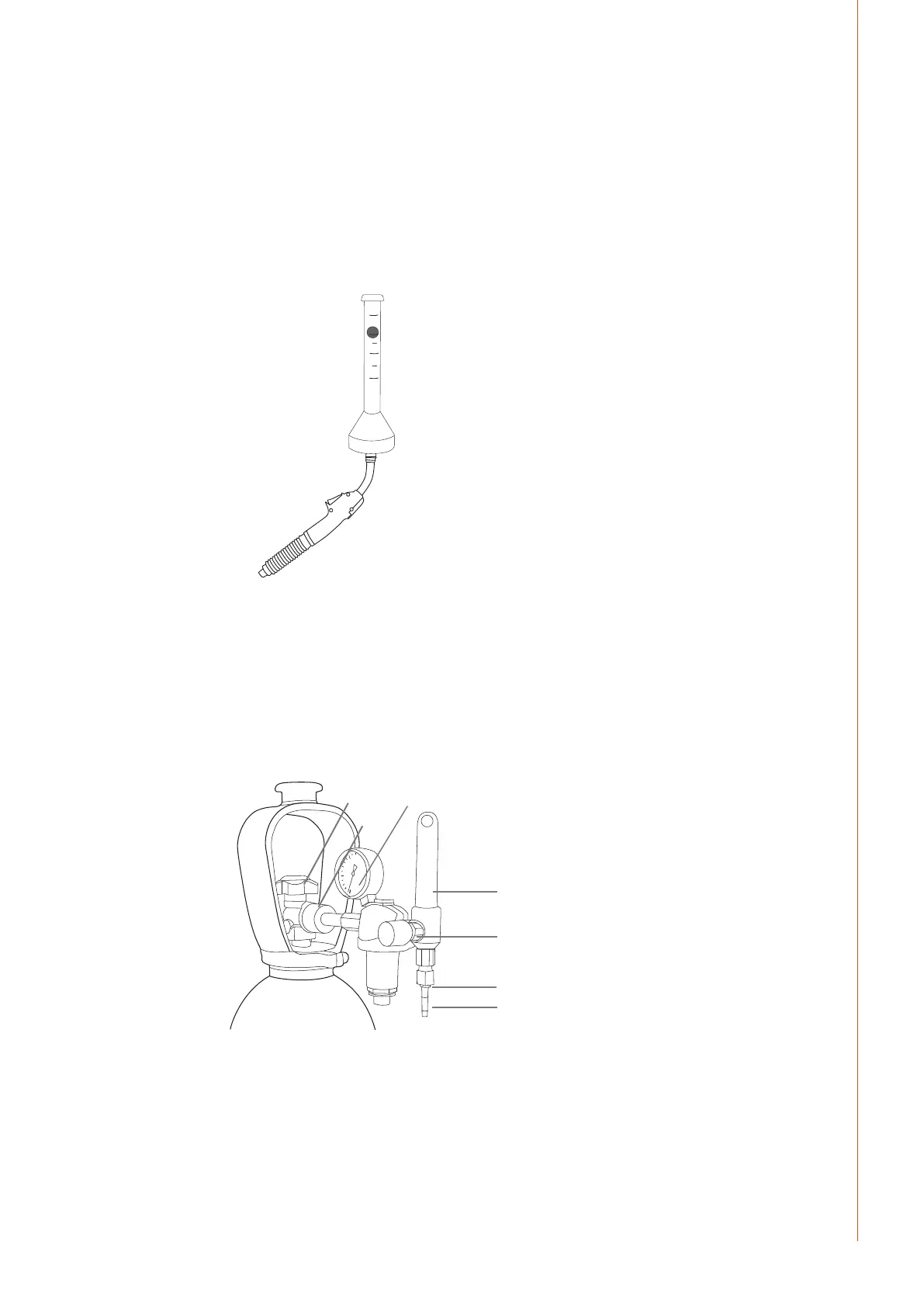

l/min

5

10

15

20

NOTE! Shielding gas ow rate from the welding gun is set according to the application, weld joint,

gas type and gas nozzle shape and size. The ow rate should be measured at the welding gun

nozzle before welding via a rotameter, and normally measure's between 10 – 20 litres per minute

for many welding applications.

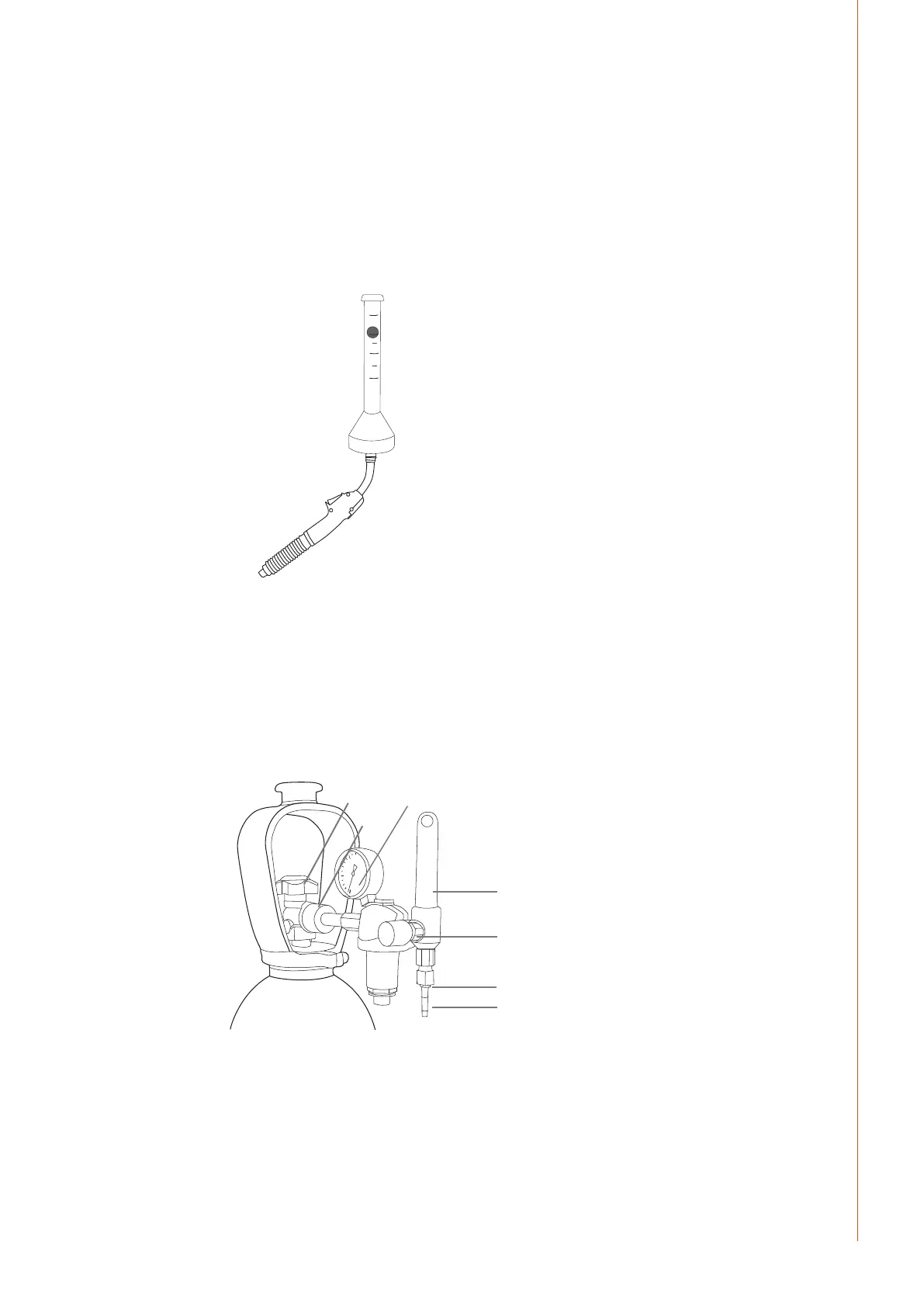

2.14.1 Installing gas bottle

Always fasten the gas bottle properly in the vertical position, in a special holder against the

wall or on a cylinder carriage. Remember to close gas bottle valve after welding.

Parts of gas ow regulator

5

2

4

7

1

6

3

1. Gas bottle valve

2. Flow regulation screw

3. Connecting nut

4. Hose tail

5. Hose tail nut

6. Gas bottle pressure gauge

7. Shielding gas ow meter

Loading...

Loading...