WFX 200, 300, 200 P Fe/Ss, 300 P Fe/Ss, 200-T, 300 P-T, 300-T, 200 AMC, 300 AMC

20

EN

3.4 Welding software

The FastMig WFX wire feeders are compatible with the following modied welding processes

and functions

• WiseRoot+™ is a modied welding process for open gap root welding without backing.

• WiseThin+™ is a modied welding process developed especially for ecient welding for

thin sheets and position welding, also with the CO

2

shielding gas.

• WiseFusion™ is a welding function for ensuring consistent weld quality in all positions.

• WisePenetration™ is a welding function for delivering constant welding power

regardless of changes in the stick out length.

• MatchLog™ contains MiniLog™ function and the MatchChannel™ function for quickly

changing welding parameters on the run.

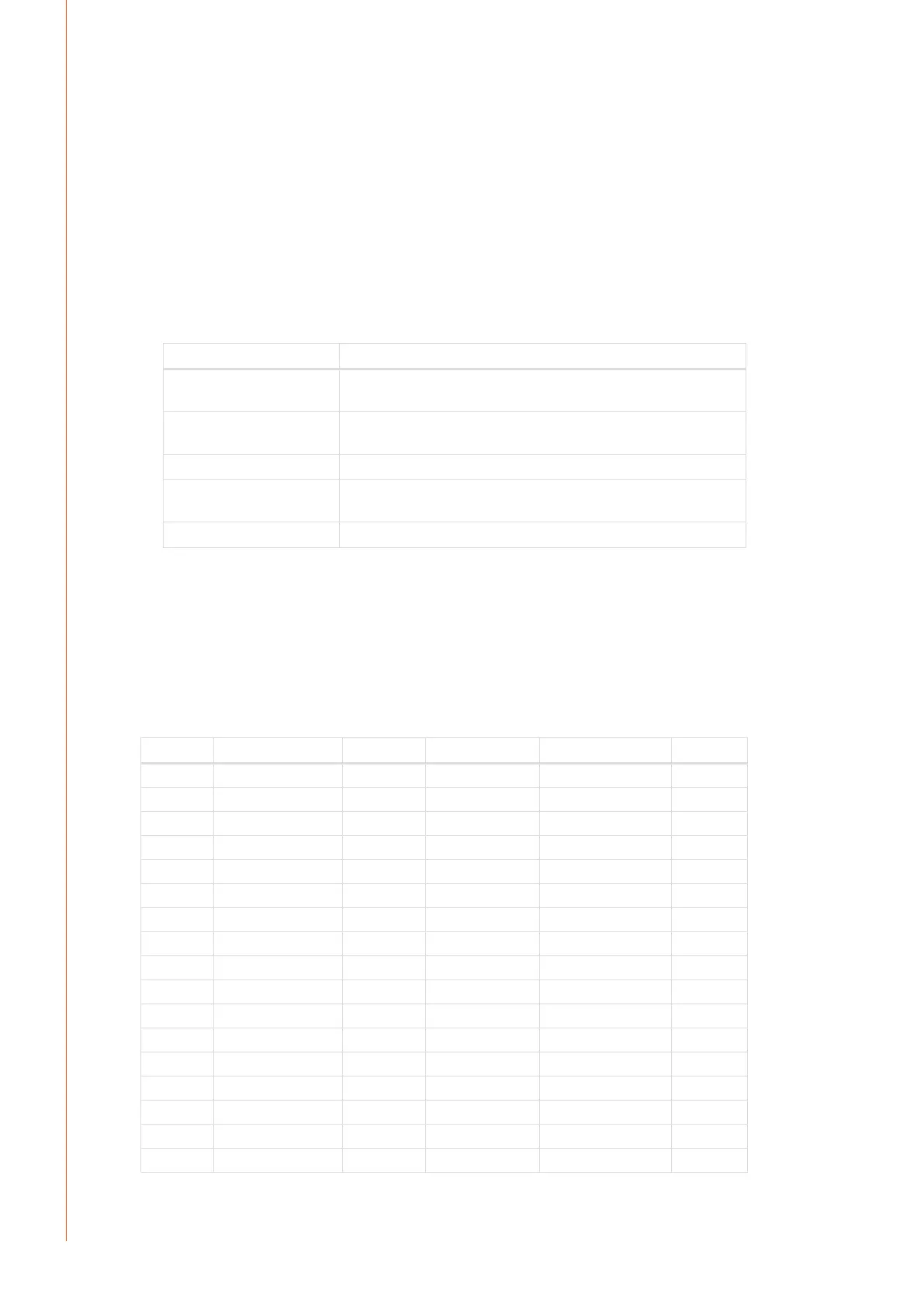

Wire feeder Factory-installed

WFX 200, 300

WiseFusion

WorkPack

WFX 200 P Fe, 300 P Fe

WiseFusion, WiseRoot+, MatchLog

Pipe Steel pack FE

WFX 200 P Ss, 300 P Ss

WiseFusion, WiseRoot+, MatchLog, Pipe Stainless pack Ss

WFX 200 AMC, 300 AMC

WiseFusion, WisePenetration, WiseThin+, MatchLog,

Steel Pack, Steel Pack for WiseThin+, Stainless Steel Pack, Aluminium Pack

WFX 200-T, 300 P-T, 300-T

MIG as standard. Other welding software factory-installed according to order.

If your welding needs change and you wish to update your system in the future, you can order

additional welding programs or other welding software and load them to your system with

Kemppi DataGun eld programming device. Optional features can be purchased through

Kemppi DataStore.

For further information about the available welding programs, modied processes

and special enhanced arc performance solutions, visit Kemppi web site at

www.kemppi.com or contact the local Kemppi dealer.

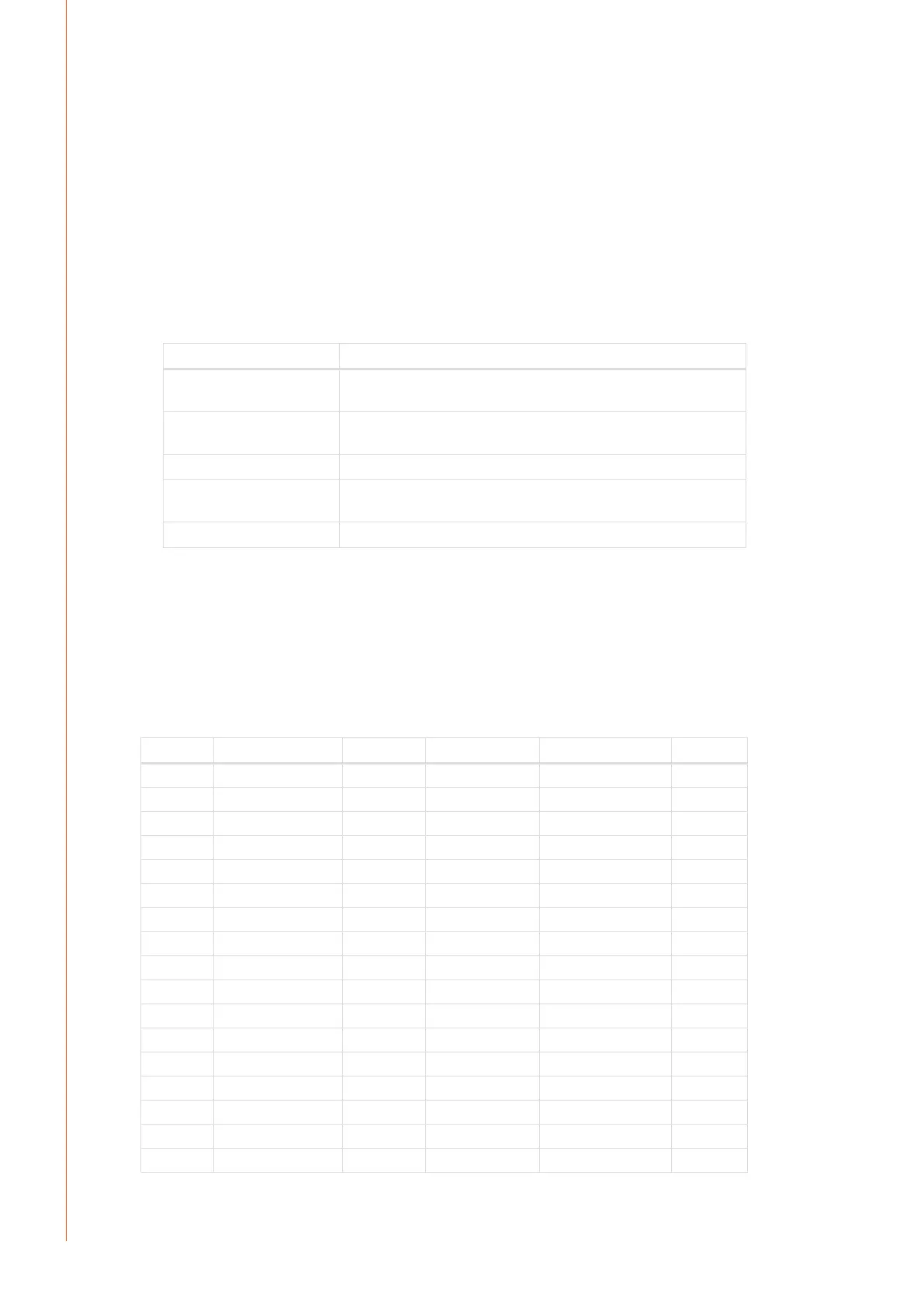

PIPE STAINLESS PACK

Group Material Wire ø (mm) Shielding gas Process Number

Ss CrNiMo 19 12 0.8 Ar+2%CO₂ WiseRoot+ S01

Ss CrNiMo 19 12 0.9 Ar+2%CO₂ WiseRoot+ S02

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ WiseRoot+ S03

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ WiseRoot+ S04

Ss CrNiMo 19 12 0.8 Ar+2%CO₂ 1-MIG S01

Ss CrNiMo 19 12 0.9 Ar+2%CO₂ 1-MIG S02

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ 1-MIG S03

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ 1-MIG S04

Ss FC-CrNiMo 19 12 1.2 Ar+15–25%CO₂ 1-MIG S84

Ss FC-CrNiMo 19 12 1.2 CO₂ 1-MIG S85

Ss MC-CrNiMo 19 12 1.2 Ar+2%CO₂ 1-MIG S87

Ss CrNiMo 19 12 0.8 Ar+2%CO₂ Pulse/Double Pulse S01

Ss CrNiMo 19 12 0.9 Ar+2%CO₂ Pulse/Double Pulse S02

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ Pulse/Double Pulse S06

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ Pulse/Double Pulse S04

Ss CrNiMo 19 12 1.0 Ar+He+CO₂ Pulse/Double Pulse S26

Ss CrNiMo 19 12 1.2 Ar+He+CO₂ Pulse/Double Pulse S24

Loading...

Loading...