KEOFITT W9 USER MANUAL V.4 PAGE 14

3.7 Membranes

All valve heads may be delivered with any of the 4 materials: Silicone, EPDM, PTFE and FFKM.

The only exception is the MicroPort Valve head, for which membranes are only available in Silicone and

EPDM.

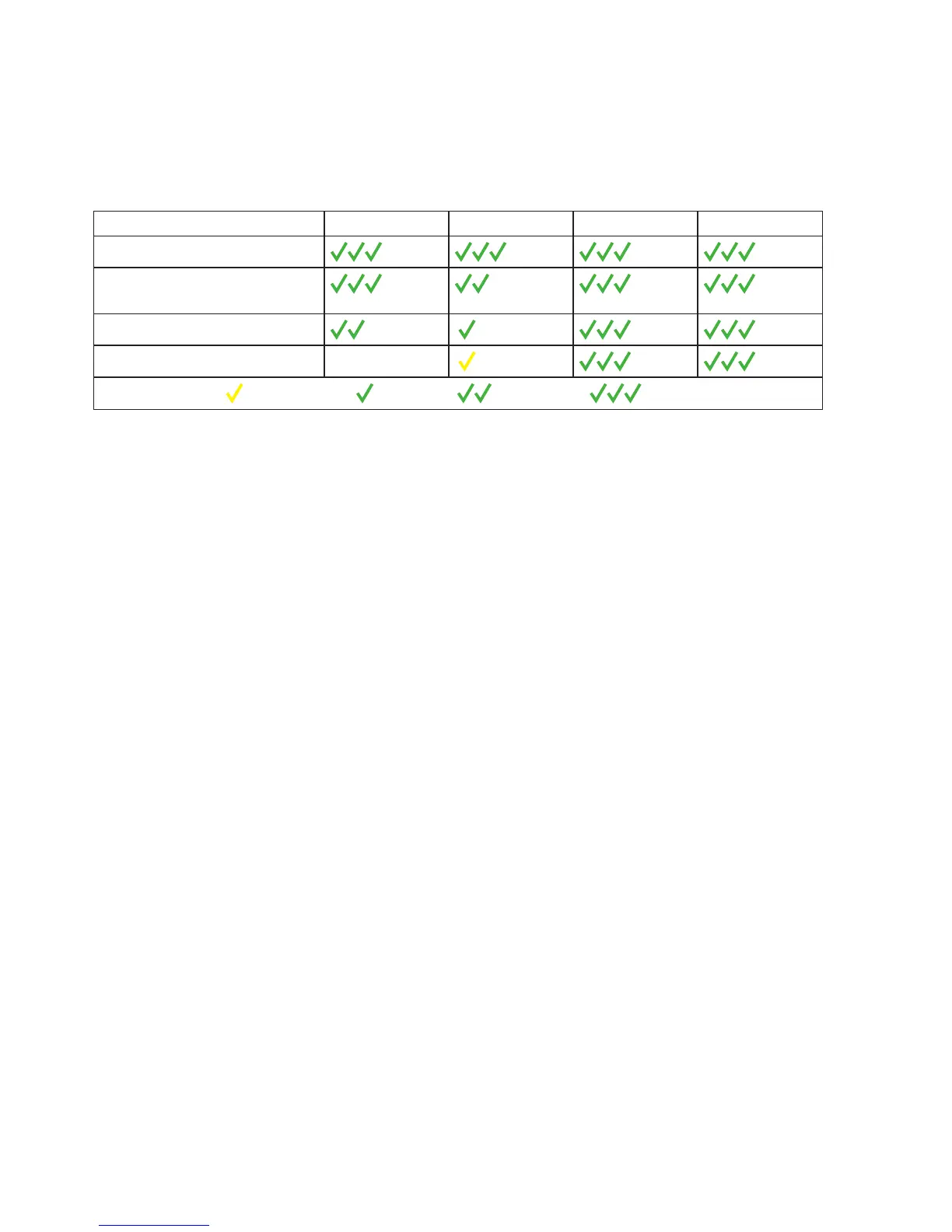

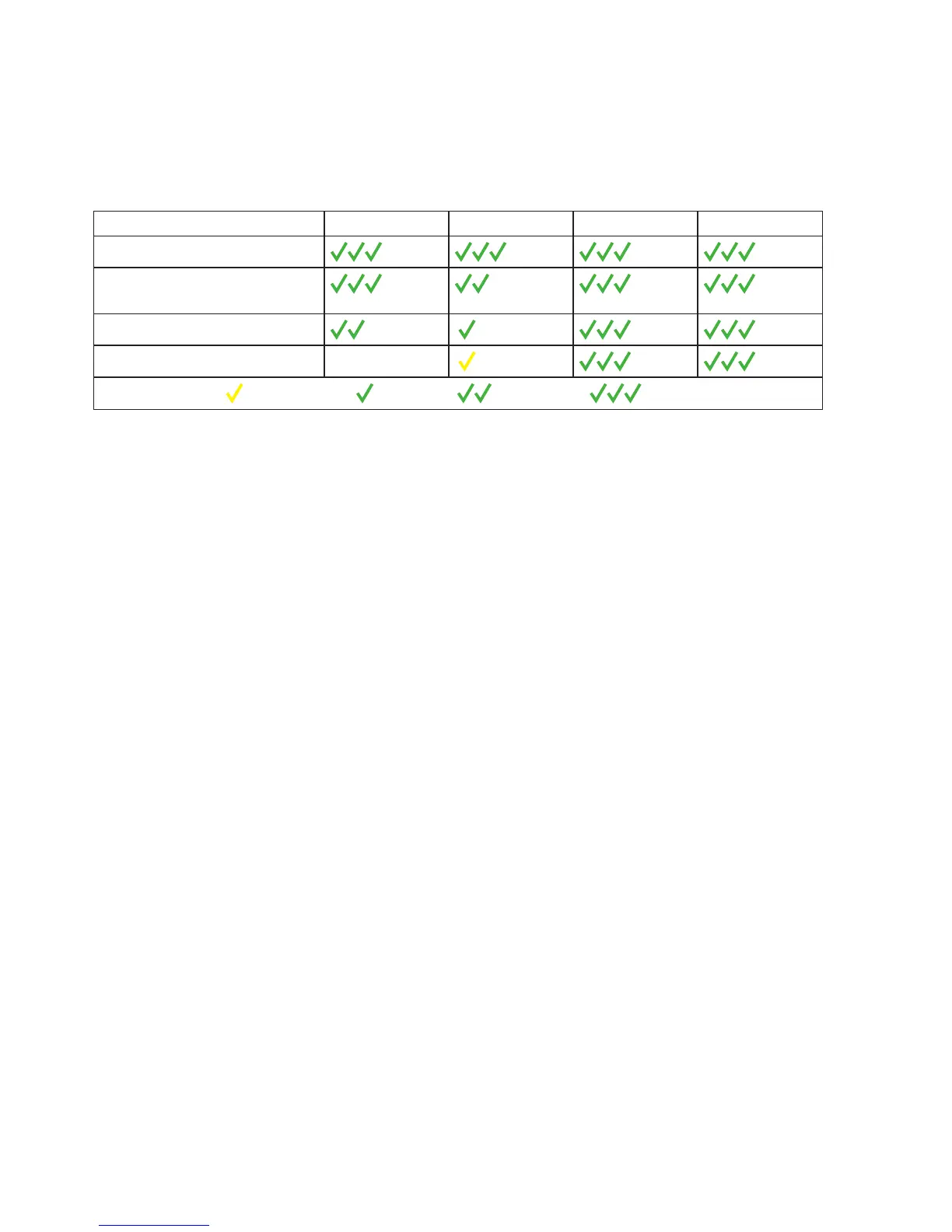

They all have dierent properties and dierent resistance to various chemical substances, as seen in the

table below.

Resistance to - EPDM Silicone PTFE (Teon) FFKM

- weather and Ozone

- hydrolysis (water and

steam)

- to acids and bases

- mineral oil and gas

X

X=not suitable =less suitable =Suitable =Very Good =Excellent

Put in words the properties can also be described like this:

• The Silicone membrane has the advantage that it in general can withstand high

temperatures, but it cannot tolerate moisture condensation resulting from steam

sterilisation

• The EPDM membrane is better able to cope with the condensation in the steam and at

the same time it can be used with a majority of CIP uids and disinfectants in normal

concentrations

• The PTFE membrane resists all CIP uids and disinfectants except highly oxidising acids in

high concentrations

• The FFKM covers the highest temperature range and has excellent chemical resistance to

virtually any chemical compound

Membranes in rubber materials like EPDM, Silicone and FFKM are fully interchangeable (except for the

MicroPort version). This means that you may change from for instance Silicone to EPDM, if required.

However, valve heads with PTFE membranes are designed dierently from the others. As PTFE is a sti

material with no elastic properties, it cannot be stretched. Therefore, it is made with a bellow to allow for

the valve movement.

If you would want to upgrade from Silicone/EPDM to PTFE, it is necessary to contact your local Keott

dealer or Keott directly.

NOTE! The membrane functions as a dynamic seal in the valve seat as well as a hygienic static

sealing against the valve head.

Loading...

Loading...