KEOFITT W9 USER MANUAL V.4 PAGE 16

3.10 Valve cleaning / disinfection / sterilisation

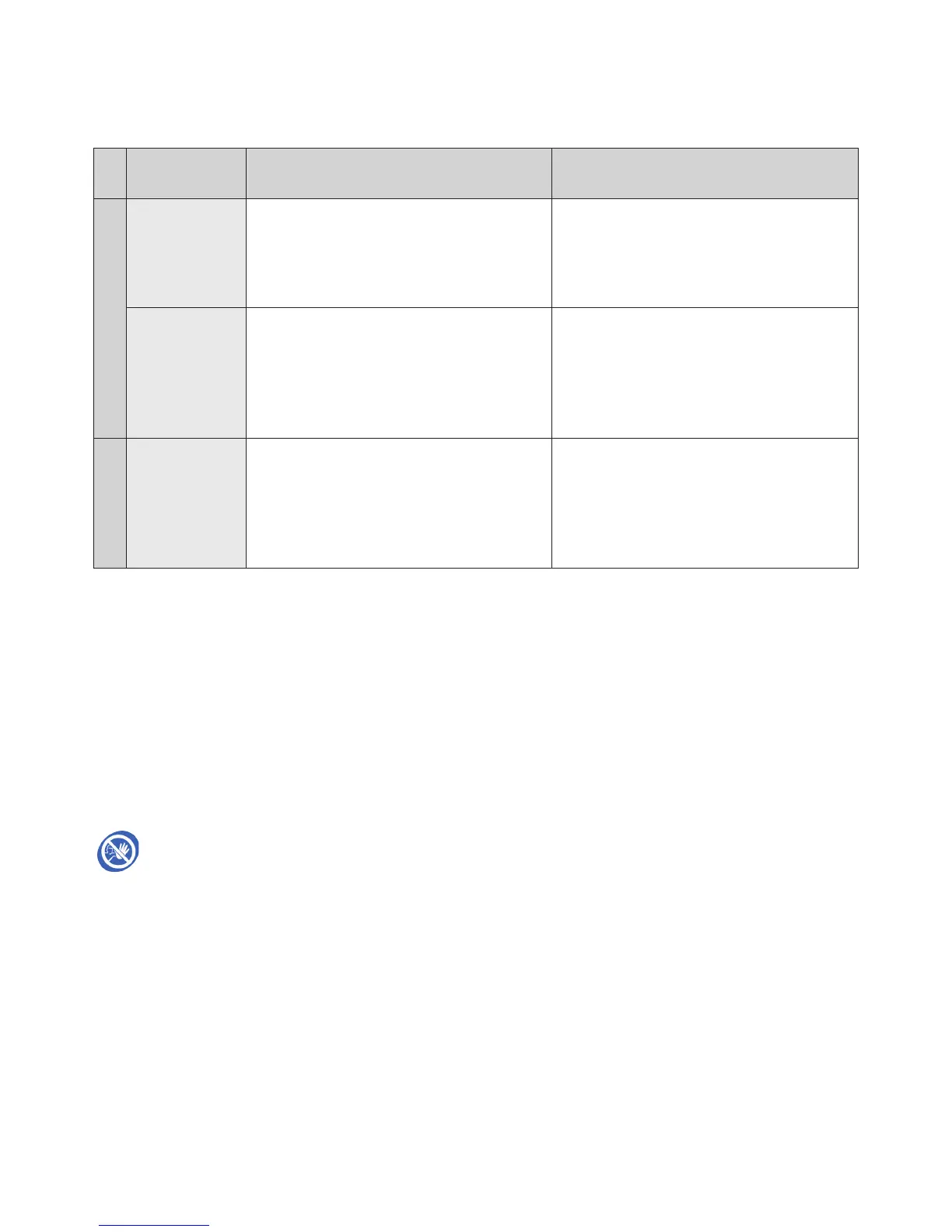

The table below describes the two fundamentally dierent ways of preparing the valve for sampling,

1) Chemical cleaning/disinfection and 2) Steaming:

Method Description Pros & Cons

Chemical

Chemical

cleaning

Liquid detergents are used to clean the

valve.

CIP = Clean-In-Place

This process is adopted where steam

is not available or where the product

cannot withstand the exposure to heat.

Involves several stages with ushing,

cleaning and rinsing between batches.

Chemical

disinfection

A disinfection process using an

appropriate chemical liquid disinfectant

usually follows the cleaning process.

The valve interior is wetted, soaked

or ushed with an appropriate

disinfectant.

It adds 2 more stages to the CIP:

application of disinfectant and nal

rinse.

Involves handling of potentially

hazardous chemicals.

Thermal

Sterilisation Steam is supplied for 1 minute just

before and immediately aer sampling.

Steaming does ushing, cleaning,

rinsing and sterilisation in one

operation.

Steaming may be less suitable with very

heat sensitive products.

Steaming entails the risk of burns.

Flushing with water followed by the supply of a chemical detergent through the upper of the valve’s two

hose pieces results in cleaning the valve (CIP). It is the perfect, hygienic design and surface nish of the

inner part of the valve, which enables easy, eicient and reliable cleaning in a closed state of the valve.

Supplying steam through the upper of the valve’s two hose pieces results in cleaning and sterilisation. It

is the perfect, hygienic design and surface nish of the inner part of the valve, which enables sterilisation

in a closed state. According to an EHEDG based test conducted by the Biotechnological Institute in

Denmark, the valve is sterile aer just 1 minute’s supply of steam at a pressure of 1 bar(g), 121 ºC.

Steaming is therefore an SIP process (Sterilise-In-Place).

Following CIP or SIP, but prior to sampling, a sterile plug of rubber or stainless steel is tted to the top

hose piece. When the valve is opened the process product will run out of the lower hose piece.

WARNING

• During sterilisation with steam the valve will become hot and care should thus be taken when

operating the valve

• The valve is designed for use in working conditions of up to 6 bar(g) pressure and temperatures

of up to 121 C. It is therefore important to be aware that the rubber plug (designed for max. 3

bar(g)) or the steel plug (designed for max. 10 bar(g)) may be forced out at high speed, if not

seated properly

• When steaming always use dry saturated steam without condensation at max. 1 bar(g). At higher

pressure the membrane may be damaged/split

• Always remember to use safety goggles when steaming, CIPping, taking samples and all other

operations of the sampling valve

Loading...

Loading...