KEOFITT W9 USER MANUAL V.4 PAGE 24

choice of valve head). It is therefore important to be aware that the rubber plug (designed for

max. 3 bar(g)) or the steel plug (designed for 12 bar(g)) may be forced out at high speed, if not

seated properly

• For valve heads allowed under ATEX for Group IIGD, Category 2 (zone 1) both handle and top of

valve heads N and Q must be cleaned before use

• Always remember to wear safety goggles when steaming, CIPping, taking samples or any other

operations of the sampling valve

IMPORTANT

• Don’t attach a steam trap to the hose from the valve steam outlet (lower hose piece) as it will

impede the ow of steam and hence the ushing eect, and make the sterilisation dependant

on temperature only, demanding a much longer sterilisation time

• If the steam capacity is low and/or the outlet hose from the valve is short and/or with a large

diameter, the temperature will drop and condensation may occur in the valve chamber. In this

case a counter pressure must be established using a pressure relief valve or a needle valve at the

outlet

• Leave the steam hose in place to prevent contamination from the ambient during sampling. If

removal of steam hose is required, t a sterile rubber or stainless steel plug onto the upper hose

piece

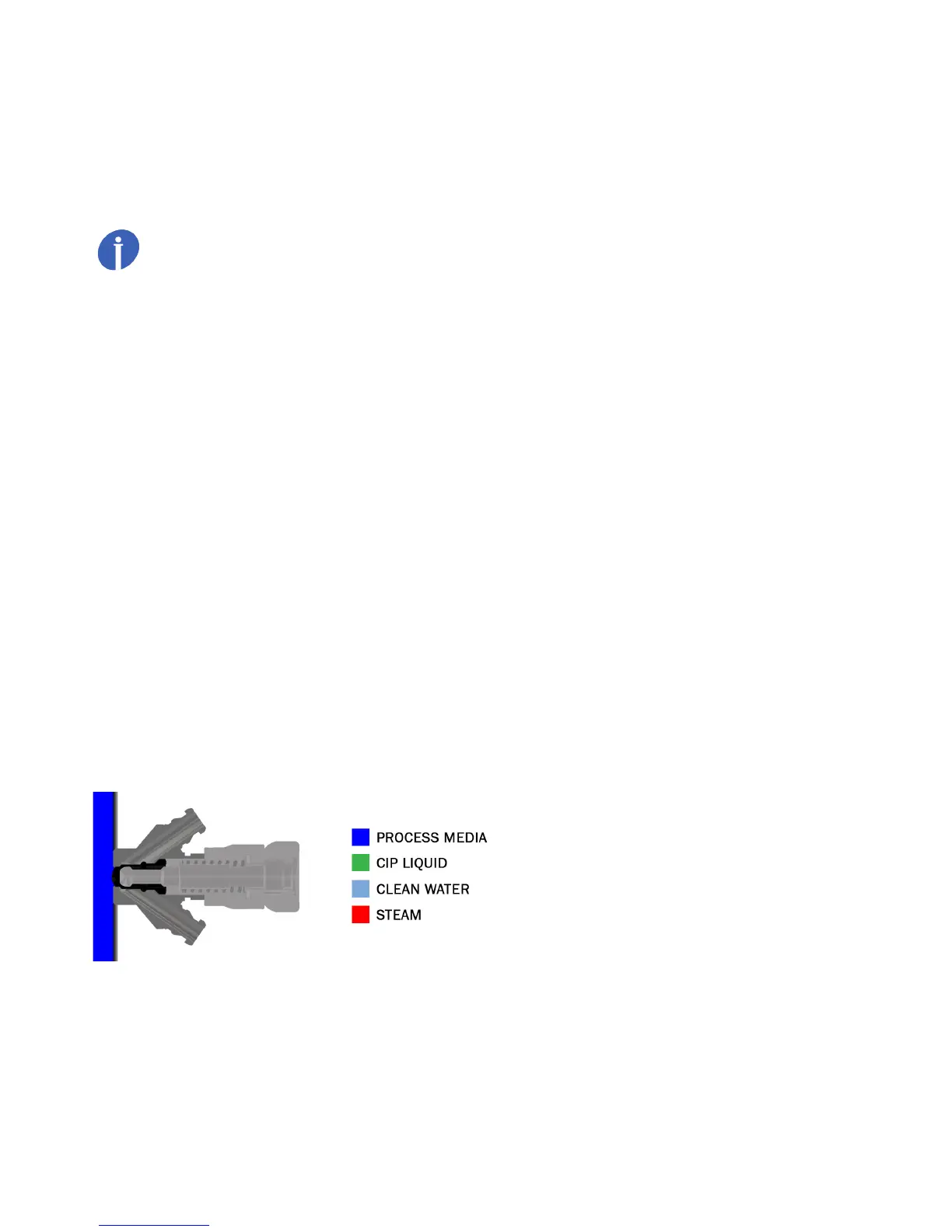

5.4 Sampling

Prepare a recipient for your sample.

For aseptic sampling use steam and a Keott Aseptic Sampling Bag (available in dierent sizes; please

see datasheet on www.keott.dk). Leave the steam hose in place to prevent contamination from the

ambient during sampling.

For all other sampling use a Keott Sterile Sampling Bag or a Spike Bag, which provides a closed ow

path for your sample protected against the ambient. Alternatives are bottles with a screw cap, jars or any

other available container. If removal of steam/CIP hose is required, t a sterile rubber or stainless steel

plug onto the upper hose piece

Take the sample immediately aer cleaning/disinfection/sterilisation performing the following steps:

Loading...

Loading...