20

EN

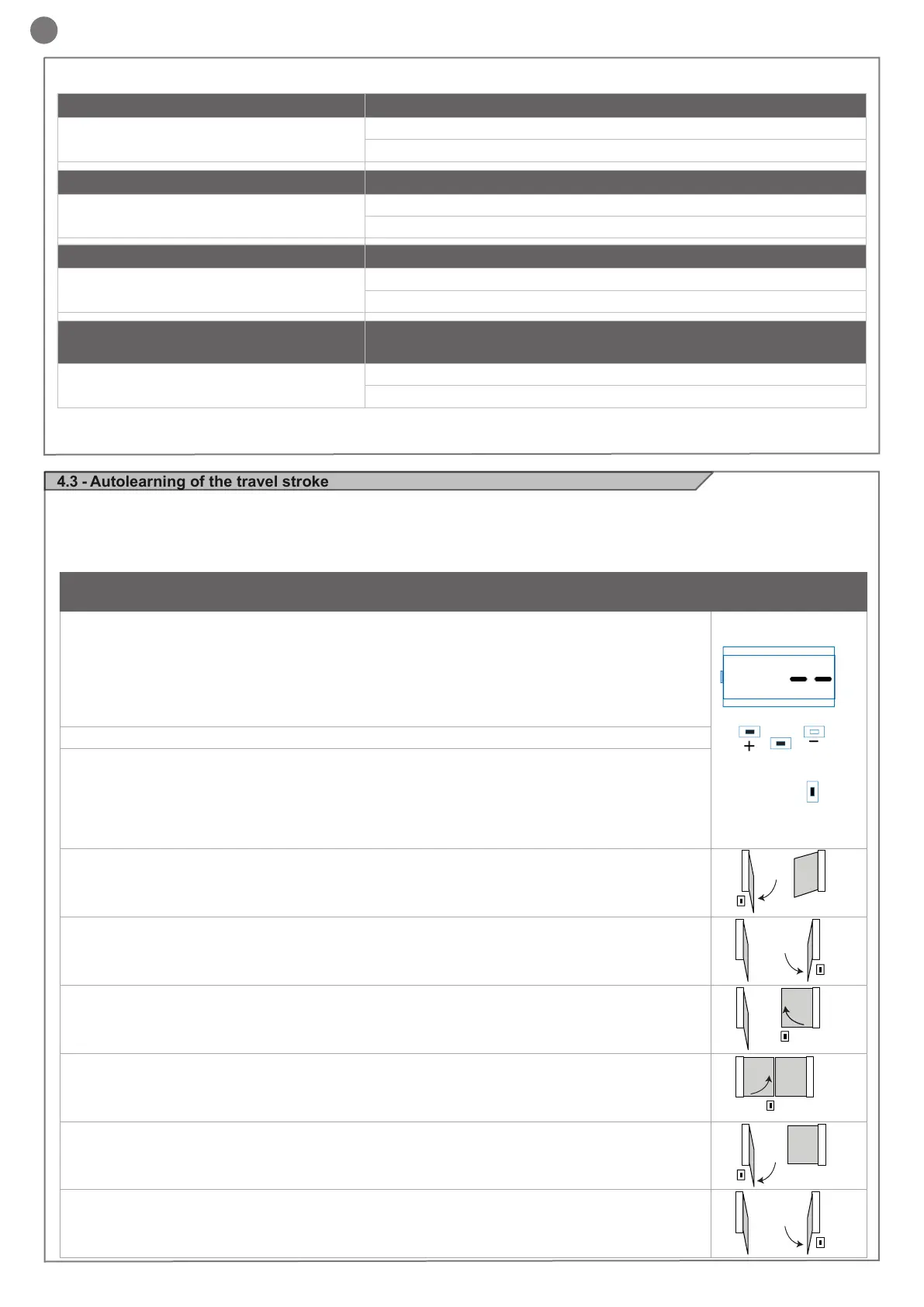

4.3 - Autolearning of the travel stroke

The rst time the control unit is powered up, an autolearning proce-

dure must be carried out to acquire fundamental parameters such

as the travel stroke length and deceleration points.

Press the + or - keys to view not only the status of the control unit, as

After eliminating the cause of the alarm, to delete all errors simply

press the “DOWN -” key or press the SS (STEPPING) command

explained in the rst table in point 4.2, but also the count of the ope-

ning-closing operations performed. In the operation count display,

thousands, displayed without dots, alternate with units, displayed

with dots between them (e.g.: 50.000 = 50/0.0.0).

The display returns to the normal screen.

Malfunctions

This section lists a number of malfunctions which may occur.

SURGE OVERLOAD ALARM The motor’s current drawdown has increased very quickly

EFO

1. Leaf impact with obstacle.

2. Gate rubs during opening/closing

SAFETY EDGE ALARM The control unit has received a signal from the safety edge

EED

1. The safety edge has been pressed.

2. The safety edge is not connected correctly.

PHOTOCELL ALARM Phototest fail outcome

EPH

1. Check the photocell connections.

2. Check that the photocells are operating correctly.

ELECTRONIC OVERLOAD CUTOUT

TRIPPED

Motor not absorbing power

Eth

1. Check the motor’s power drawdown.

2. Check that the gate travels smoothly and that there are no obstacles.

AUTOLEARNING OF THE TRAVEL STROKE AND MAIN PARAMETERS, WITH

PRESET DECELERATIONS

The deceleration intervals are as set in the menu, with the same percentage applied during opening and

closing.

CAUTION: if manual programming of deceleration intervals is required, go to the next table

1. CAUTION! check that mechanical end stops (compulsory) are present and secure. The motors must

always reach the mechanical end stop

2. Move the gate manually to mid-travel.

3. Press the pushbuttons UP + and MENU at the same time for at least 5 seconds until LOP is displayed, then

(if necessary) press DOWN (see gure).

Ensure that motor M1 is activated rst; otherwise, press DOWN -, turn the power off and invert connections

M1 and M2. Repeat the procedure from step 3.

If the rst manoeuvre is NOT opening, press DOWN - to stop the self-learning process. Then press SS to

restart acquisition: the leaf resumes movement in the correct direction.

4. Motor M1 opens at low speed until it reaches the mechanical opening end stop.

At precisely the time of reaching the mechanical opening end stop, press the SS command.

Motor M2 starts automatically in opening mode. If motor M2 moves in closing, stop by pressing DOWN - and

resume movement using SS (the leaf resumes movement in the correct direction)

5. Motor M2 opens at low speed. At precisely the time of reaching the mechanical opening end stop,

press the SS command. After a couple of seconds, motor M2 starts automatically in closing at full speed.

6. Precisely when motor M2 reaches the closed position, press the SS command. Motor M2 stops and

motor M1 starts in closing.

7. Precisely when motor M1 reaches the closed position, press the SS command. Motor M1 stops and

restarts in opening.

8. Precisely when motor M1 reaches the open position, press the SS command. Motor M1 stops and

motor M2 starts in opening.

9. Precisely when motor M2 reaches the open position, press the SS command. Motor M2 stops.

UP

SS

DOWN

MENU

M1

M2

4

SS

5

M1 M2

SS

6

M1

M2

SS

7

M2

SS

M1

8

M1

M2

SS

9

M1 M2

SS

Loading...

Loading...