Low Speed operation with Constant Torque

Driving a common motor at low speed for a long

time, the drive’s rated output torque will be reduced

considering the deterioration of heat dissipation

effect, so a special variable frequency motor is

needed if operation at low speed with constant

torque for a long term.

Motor’s over-temperature protecting threshold

When the motor and driver are matched, the drive

can protect the motor from over-temperature. If the

rated capacity of the driven motor is not in

compliance with the drive, be sure to adjust the

protective threshold or take other protective

measures so that the motor is properly protected.

Operation above 50Hz

When running the motor above 50Hz, there will be

increase in vibration and noise. The rate at which

the torque is available from the motor is inversely

proportional to its increase in running speed.

Ensure that the motor can still provide sufficient

torque to the load.

Lubrication of mechanical devices

Over time, the lubricants in mechanical devices,

such as gear box, geared motor, etc. when running

at low speed, will deteriorate. Frequent

maintenance is recommended.

Braking Torque

Braking torque is developed in the machine when

the drive is hoisting a load down. The drive will trip

when it can not cope with dissipating the

regenerative energy of the load. Therefore, a

braking unit with proper parameters setting in the

drive is required.

The mechanical resonance point of load

The drive system may encounter mechanical

resonance with the load when operating within

certain band of output frequency. Skip frequencies

have been set to avoid it.

Start and stop frequently

The drive should be started and stopped via its

control terminals. It is prohibited to start and stop

the drive directly through input line contactors,

which may damage the drive with frequent

operations.

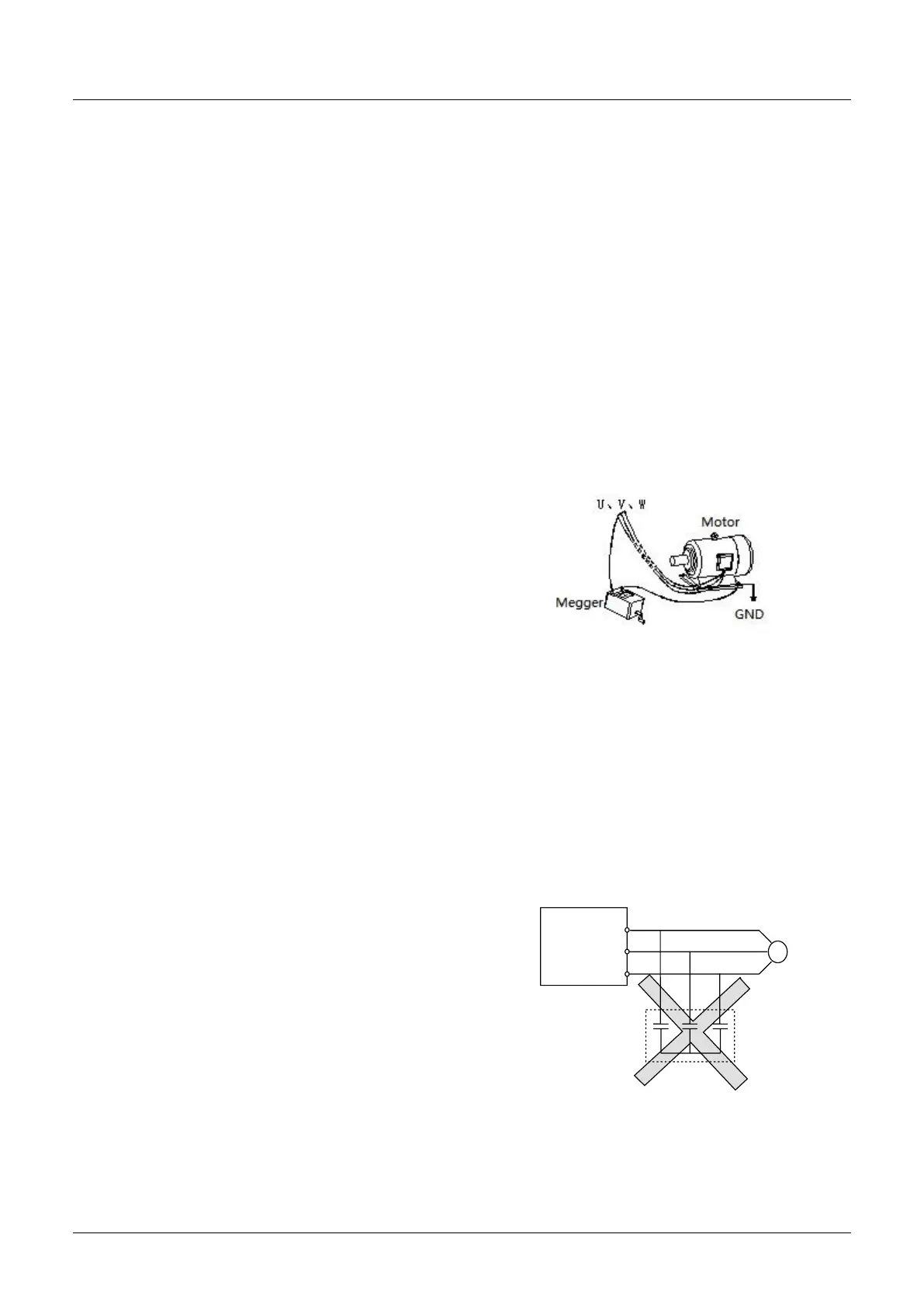

Insulation of Motors

Before using the drive, the insulation of the motors

must be checked, especially, if it is used for the first

time or if it has been stored for a long time. This is to

reduce the risk of the Drive from being damaged by

the poor insulation of the motor. Wiring diagram is

shown in Fig. 1-1. Please use 500V insulation tester

to measure the insulating resistance. It should not

be less than 5MΩ.

Fig. 1-1 checking the insulation of motor

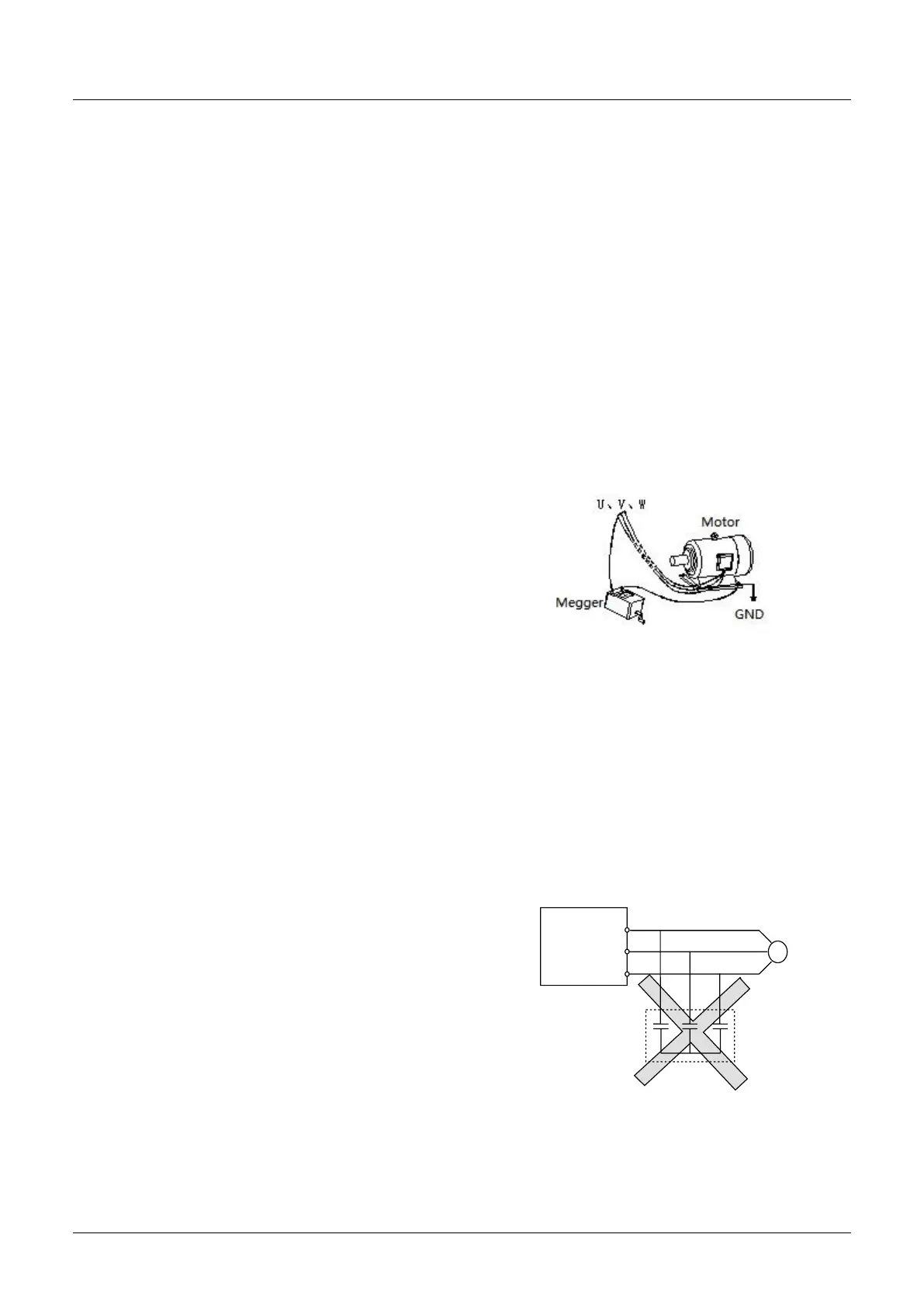

1.3.2 About Variable Frequency Drive

Varistors or Capacitors Used to Improve the Power

Factor

Considering the drive output PWM pulse wave,

please don't connect any varistor or capacitor to the

output terminals of the drive, otherwise tripping or

damaging of components may occur; as shown in

fig 1.2

Loading...

Loading...