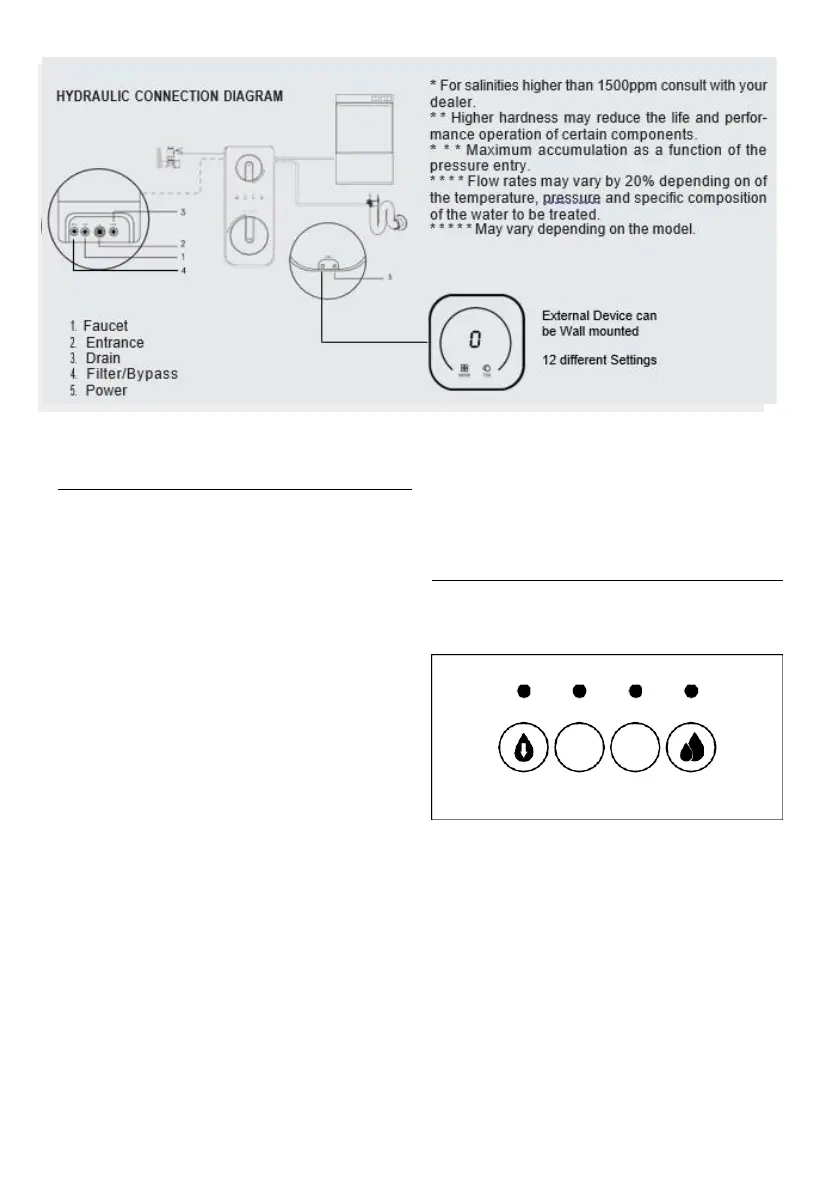

* For salinities higher than 1500ppm consult with your

dealer.

* Higher hardnesses may reduce the life and perfor-

mance operation of certain components.

** Maximum accumulation as a function of the pres-

sure entry.

**** Flow rates may vary by 20% depending on of the

temperature, pressure and specific composition of

the water to be treated.

1

2

3

4 ***** May vary depending on the model.

1.

Faucet

External Device can be Wall

2.

Entrance

mounted

3.

Drain

4.

Filter/Bypass

12 different

Settings

MODE TDS

5.

Power

2.

OPERATION

OF

THE

EQUIPMENT

user that adequate maintenance must be carried out to

guarantee the quality of the water dispensed.

•

The mains water to be treated enters the equipment

through the pre-filtration stage that incorporates a

GAC (CF) turbidity and carbon filter. In this filtration

stage, suspended particles, chlorine, its derivatives and

other organic substances are retained.

3.

INTERFACE.

SYSTEM

STATE

•

The passage of water into the equipment is controlled

by a cut-off solenoid valve (Si).

•

The water, after being treated in the filtration stage, is

driven towards the reverse osmosis (MRO) membrane.

The equipment incorporates a pump (P) to increase the

pressure. The pressure of the water on the membrane

makes the reverse osmosis process possible.

•

Before leaving the System, the water passes through

the carbon post-filter (part of MRO), which improves

the taste.

•

Reject water or water with excess salts and other dis-

solved substances is directed to the drain for disposal.

•

Direct flow equipment controls start and stop by

means of a pressure switch (HPS).

•

The equipment incorporates different functional and

/ or security systems, managed by a state-of-the-art

electronic module:

•

Electronic leak detection system (L). When the system

detects this situation, it blocks the equipment by emi-

tting an acoustic and light signal alarm. The equipment

will remain blocked until the detection probe is dry.

•

Probe for reading the conductivity of the produced

water to evaluate the state of the membrane and its

components (Q). When dispensing water from the tap,

the system will measure the conductivity of the produ-

ced water.

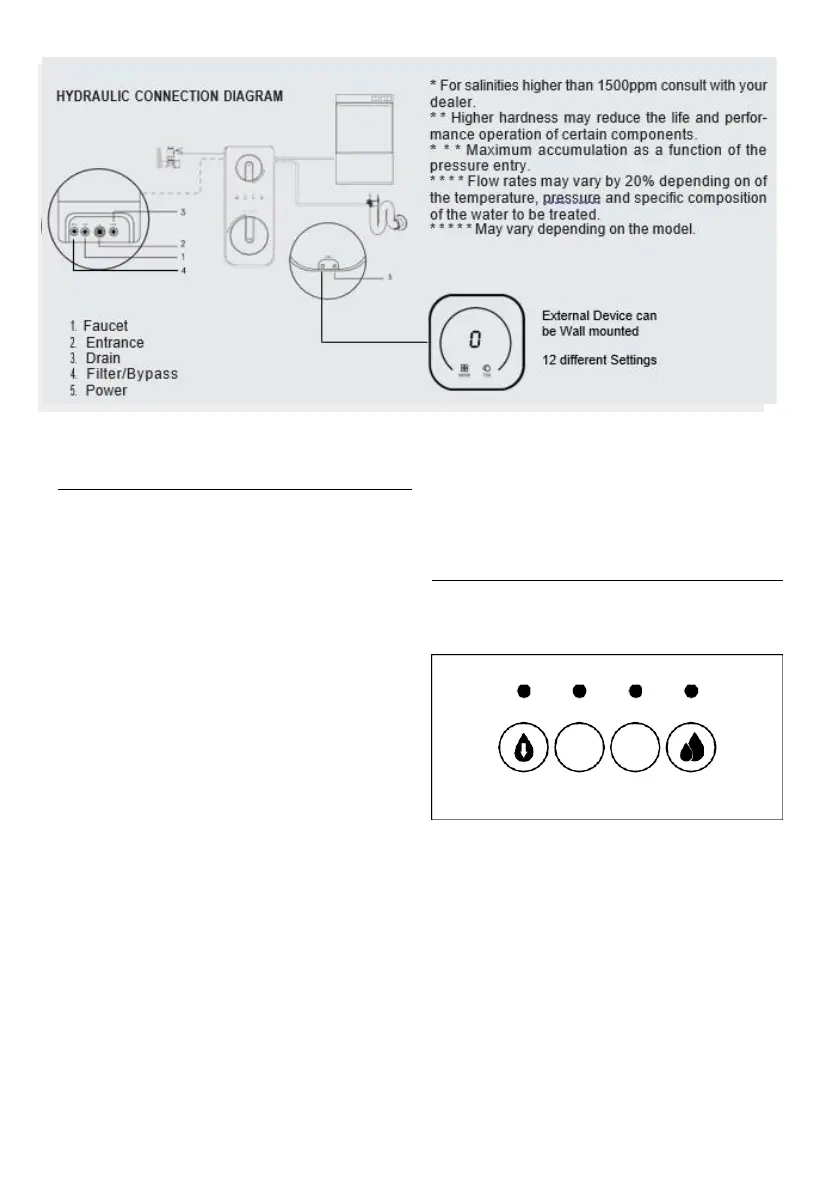

Display:

1.

Working indicator

2.

CF filter life indicator/pusher

3.

RO membrane filter life indicator/pusher

4.

Failure / quality water indicator

3.1.

COLORS OF THE WATER QUALITY INDICATOR

Blue: TDS≤200ppm*

Purple: 200ppm <TDS ≤ 300ppm*

Red: TDS> 300ppm*

*Linked to the selected Program

3.2.

OPERATION INDICATOR

It will remain illuminated in blue while the equipment is

dispensing water.

Loading...

Loading...