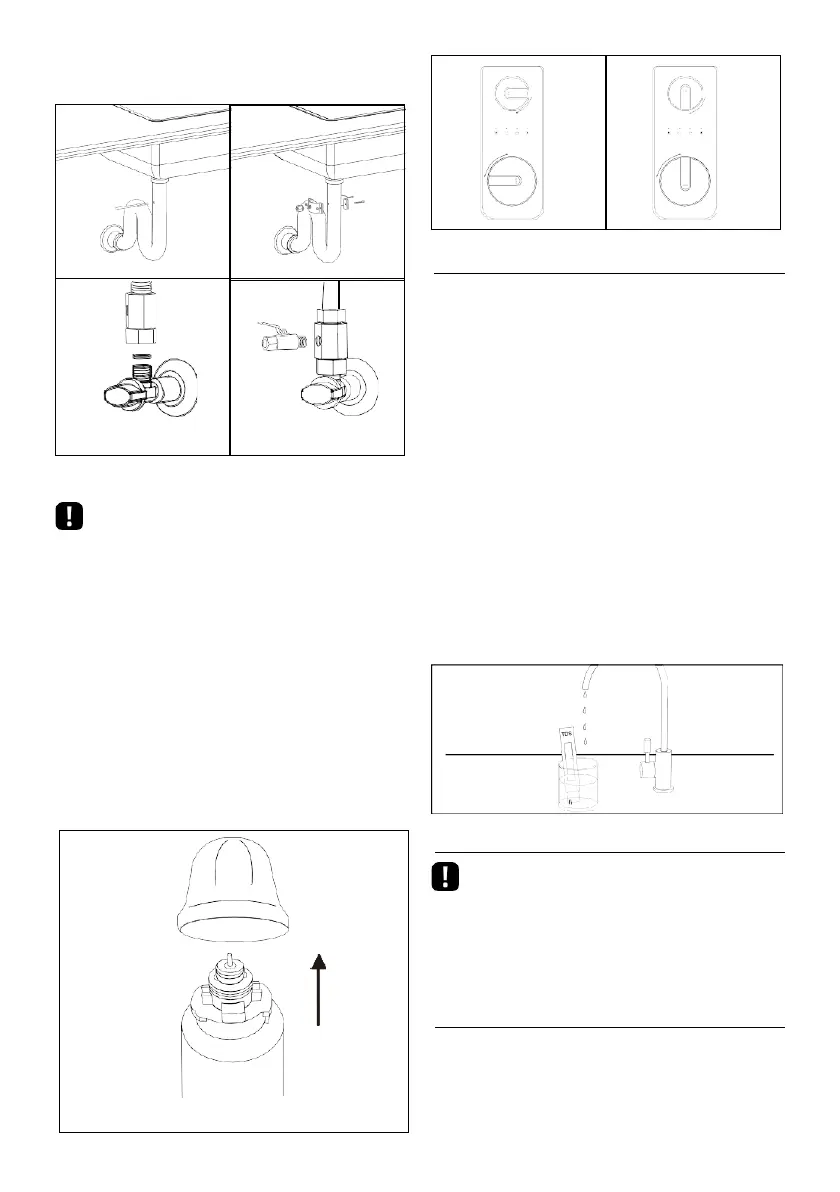

an adjoining piece of furniture. Install the production

outlet, drain collar and inlet adapter and connect them

to the respective equipment connectors (6 and 7).

See hydraulic diagram on page 13.

ATTENTION: Some of the installation accessories

may vary depending on the model and the region

in which the equipment is distributed.

5.1.

FILTER INSTALLATION

•

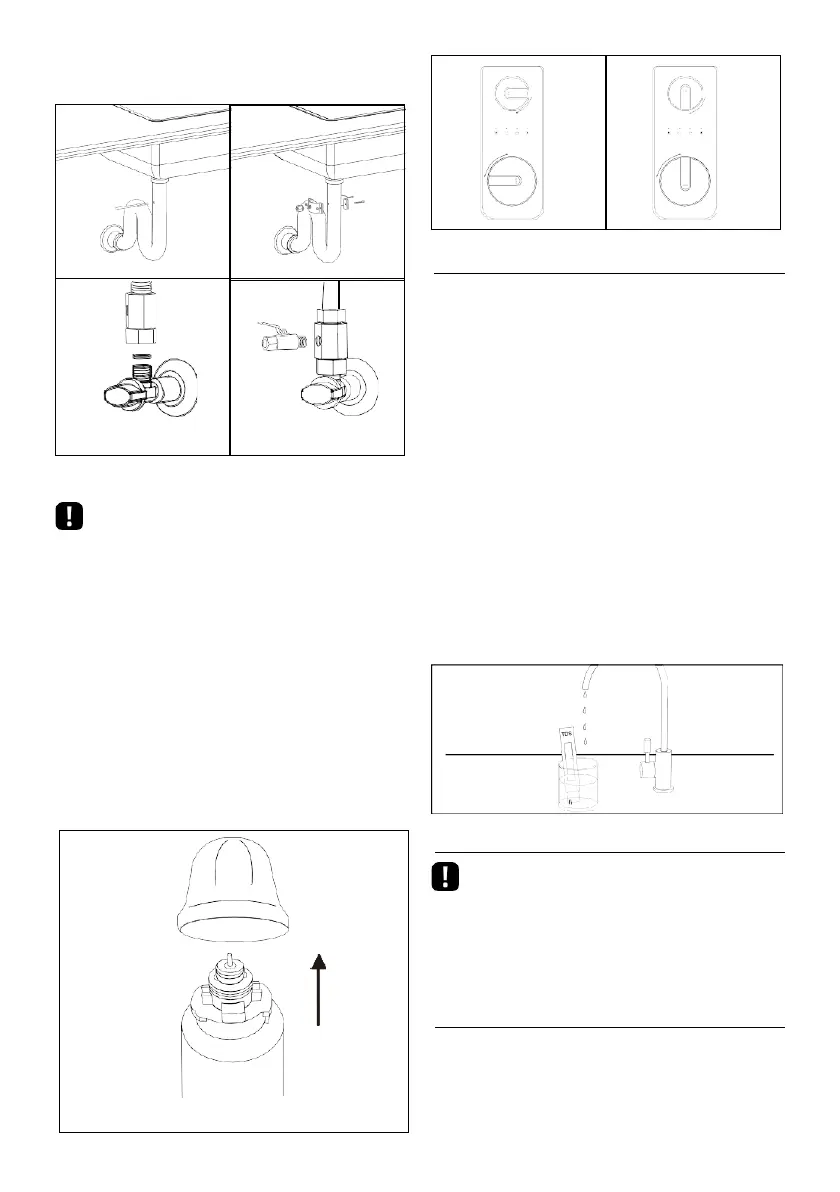

Remove the plastic wrapping and remove the protector

before installing the filters (as shown in figure 8).

•

Install the CF filter in the first stage of the Horeca machine

(upper position), the RO membrane in the second stage of

the Horeca machine (lower position).

•

To install the filters, present each filter in its respec- tive

housing with the handle in a horizontal position, as shown

in figure 9.

•

Insert firmly all the way and turn the handle 90 degrees

clockwise. After installation, the two filters should be as

shown in figure 10.

6.

START-

UP

6.1.

FILTER RINSING

•

It is necessary to eliminate the dust of the carbon filter that

is generated during the transport and handling of the equip-

ment. This dust must be eliminated since it could partially or

completely obstruct the membrane as well as cause a mal-

function of the equipment. The equipment will automatically

perform a wash when re- placing the filters.

6.2.

SYSTEM TIGHTNESS, STOP AND START

•

Close the outlet of the unit and keep the equipment hy-

draulically or electrically powered and performing a visual

inspection of the system to ensure that there are no leaks

(for approx.15min.).

6.3.

RINSE AND CLEAN

•

Open the outlet connection of the equipment and mea-

sure the quality of the water that is being produced. With a

conductivity or TDS meter, check that the reduction of salts

obtained is adequate with respect to the water to be treated

(12).

7.

MAINTENANCE

ATTENTION: Some components of your equipment,

such as the pre-filters and the membrane, are consu-

mables thathave a limitedlife.

•

The duration will depend on the quality of the local water,

consumption, type of use and specific aspects of the water

to be treated such as extreme turbidity, high chlorination,

excess iron, etc.

RECOMMENDED MAINTENANCE

CF pre-filter: at least every 6 months or 8000 l*

RO osmosis membrane: Every 3 years approx or 20.000 l for

water less than 150 ppm of hardness.

*linked to the selected Program.

•

Sanitization: At start-up. At least every 12 months de- pen-

ding on use. Every time components in contact with water in

Loading...

Loading...