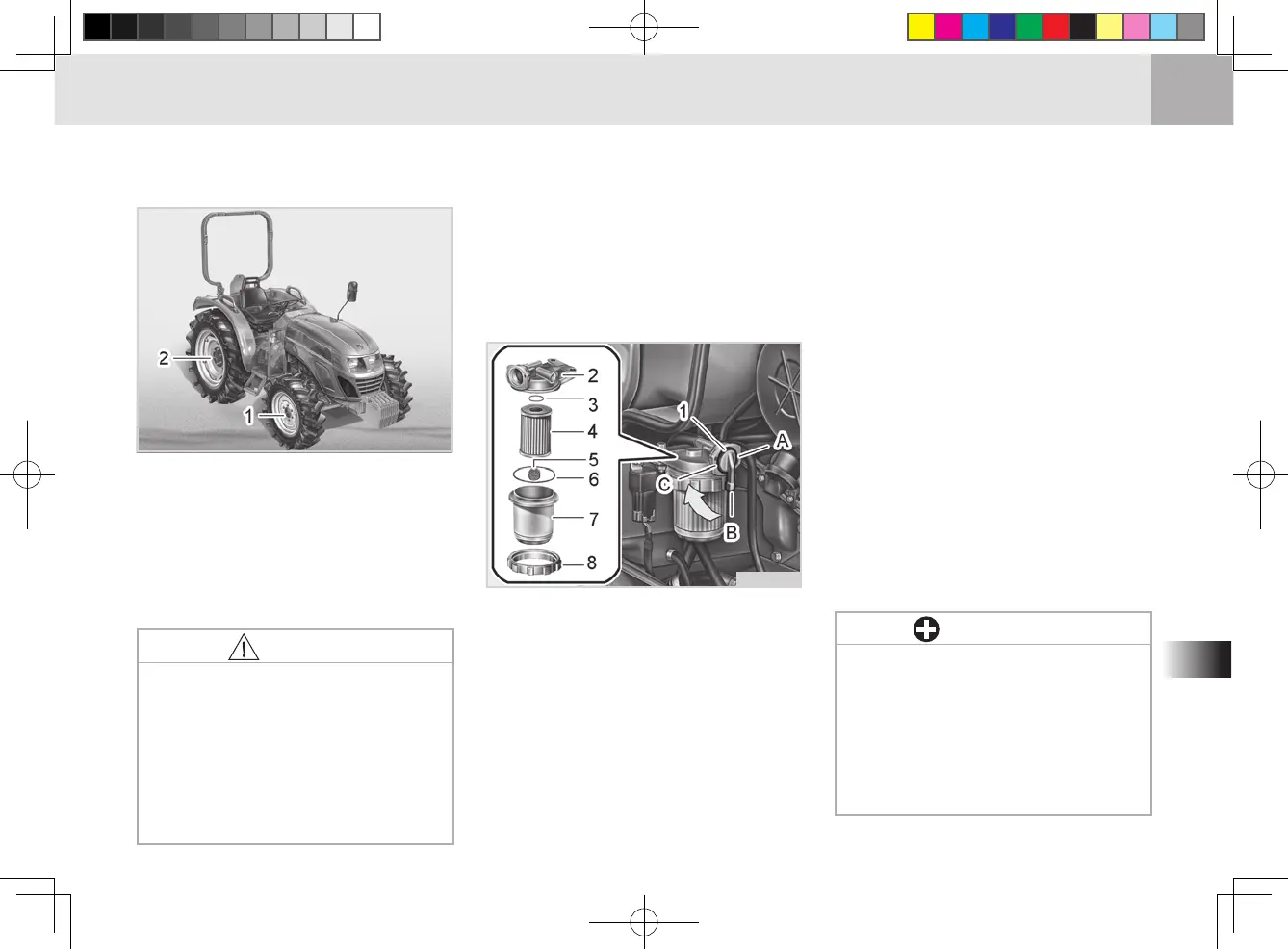

CHECKING WHEEL BOLT TORQUE

(1) Nut : 68.6 N.m (7 kgf.m, 50.6 lb.ft)

(2) Nut : 284.4 N.m (29 kgf.m, 209.8 lb.ft)

Check the wheel bolts and nuts regu-

larly especially when they are new.

If they are loose, tighten them as

specied.

EVERY 100 HOURS

ADJUSTING CLUTCH PEDAL

1. Refer to "EVERY 50 HOURS" in

page 10-8.

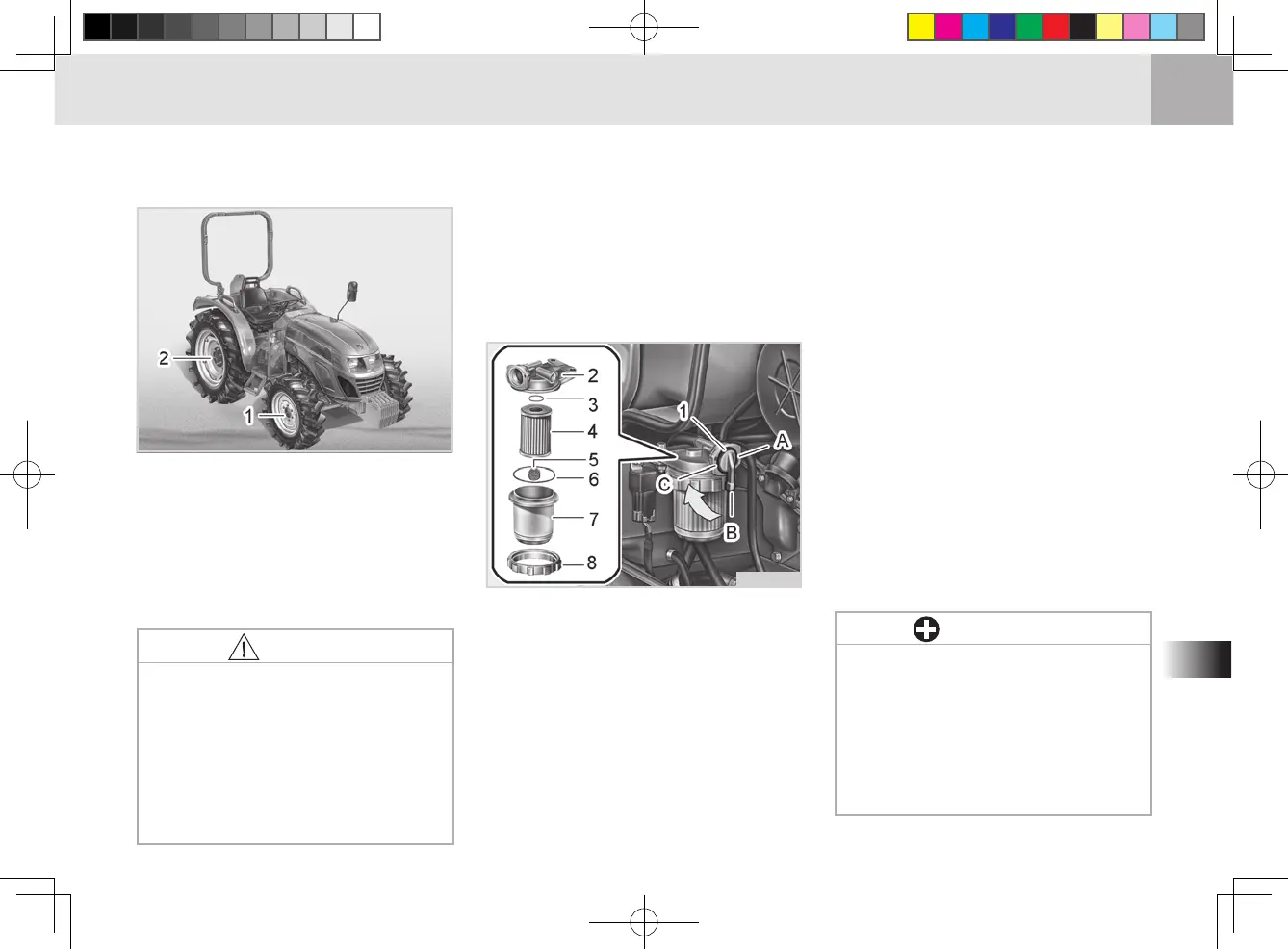

CLEANING FUEL FILTER

(1) Fuel Cock

(2)

Fuel Filter Container

(3) O-ring

(4) Filter Element

(5) Spring

(6) O-ring

(7) Filter Container

(8) Screw Ring

(A) Close

(B) Open

(C) Bleeder

t91Oa26a

S76Oa25a

This should be not performed in the

place that is not clean.

1. Close the fuel cock.

2. Loosen the ring and remove the

ltercontainer.Cleantheinsidewith

kerosene.

3.Removelterelementandimmerse

in the kerosene.

4.Reinstallthecleanedlterelement

and make sure that no dust or for-

eign material has entered.

Make sure all O-rings are in posi-

tion.

5. Bleed the fuel system. (Refer to

"Bleeding Fuel System" in the main-

tenance)

To avoid personal injury:

Never operate tractor with a

loose rim, wheel, or axle.

Any time bolts and nuts are loos-

ened, retighten to specied torque.

Check all bolts and nuts fre-

quently and keep them tight.

•

•

•

CAUTION

Contamination by dust or for-

eign materials in the fuel sys-

tem may cause premature wear

of the fuel pump and injection

nozzle. To prevent contamina-

tion, clean the fuel lter con-

tainer and element regularly.

•

IMPORTANT

Loading...

Loading...