81

Item Check method Criteria When failed

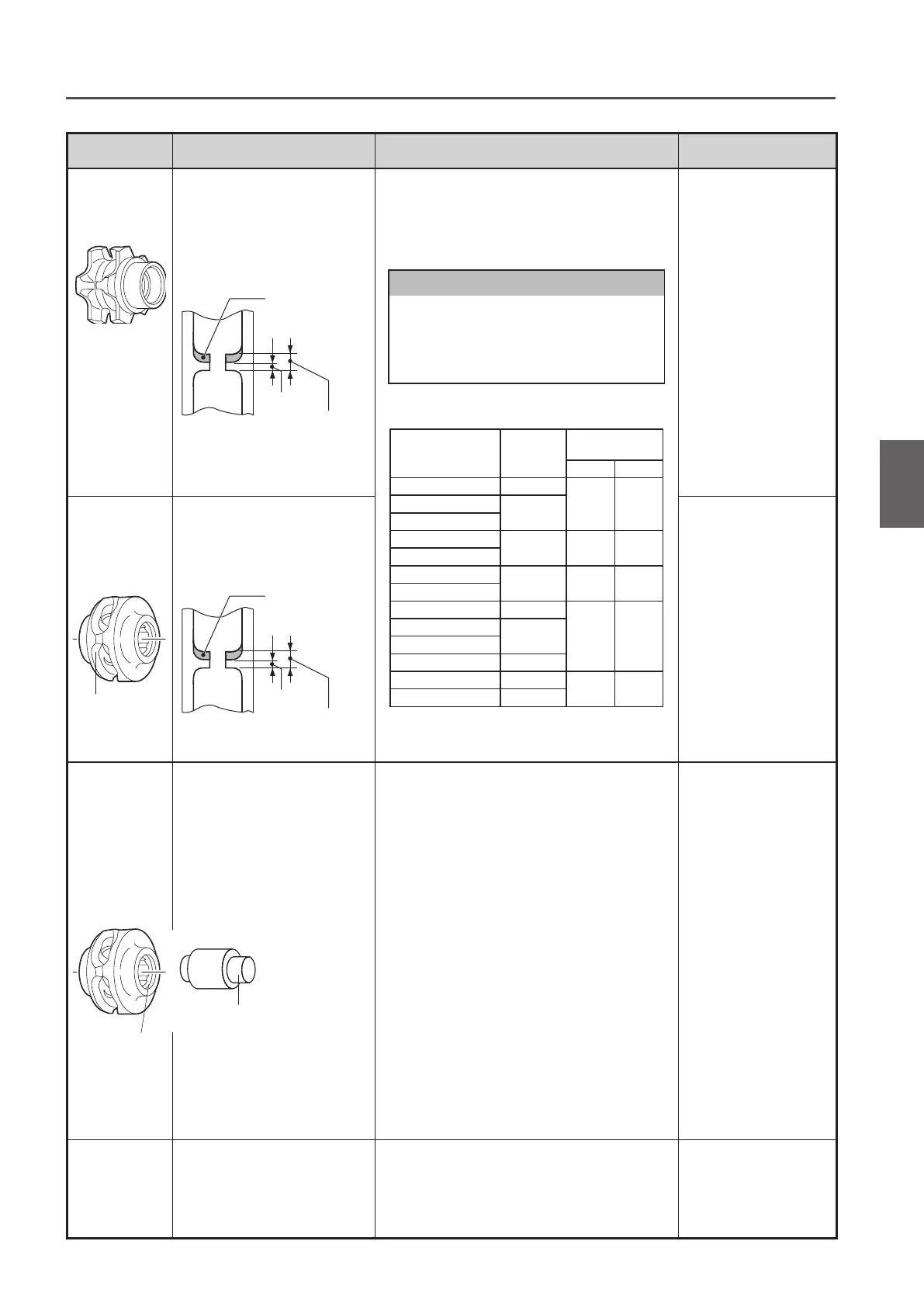

Abrasion and

flaw of the

Load Sheave

• Disassemble the Load

Sheave and check it visually.

• Measure the thickness with

vernier caliper.

Worn portion

Thickness at

purchasing

Thickness

• To have no apparent abrasion, deformation

and damage

• To have neither abrasion of the sheave pocket

northerun-onawonthecrest.

If the abrasion is observed on the Load

Sheave, the Load Chain may be worn

also. Refer to the item of Load Chain

Abrasion and check the abrasion.

NOTE

• Service limit of the Load Sheave and Idle Sheave

(Do not fall under the limit)

Code Capacity (t)

Thickness (mm)

Standard Limit

ER2-001H/IH 125kg

1.5 1.0ER2-003S/IS

250kg

ER2-003H/IH

ER2-005L/IL

500kg 3.0 2.0

ER2-005S/IS

ER2-010L/IL

1 4.5 3.0

ER2-010S/IS

ER2-016S/IS 1.6

6.5 4.3

ER2-020L/IL

2

ER2-020S/IS

ER2-032S/IS 3.2

ER2-025S/IS 2.5

7.3 4.9

ER2-050S/IS 5

Replace the Load

Sheave.

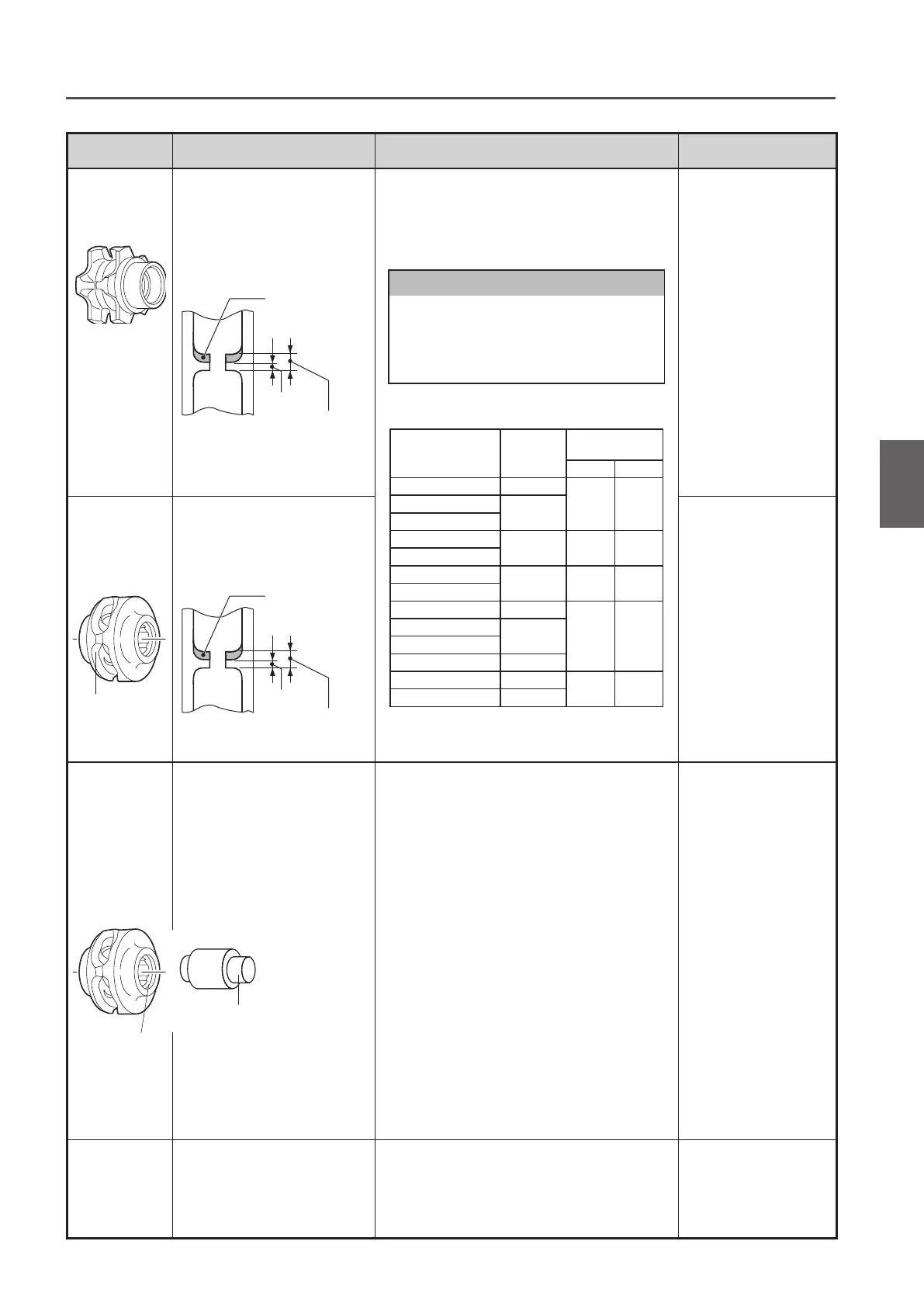

Abrasion and

flaw of the

Idle Sheave

• Disassemble the Load

Sheave and check it visually.

• Measure the thickness with

vernier caliper.

Worn portion

Thickness at

Thickness

Replace the Idle

Sheave.

Abrasion

and flaw of

the Needle

Bearing for

Idle Sheave

and Bottom

Shaft.

Needle

Bearing

Wipe off the grease applied

inside of the Idle Sheave and

Needle Bearing, and check

visually for Needle Bearing and

Bottom Shaft.

• No deformation and damage.

• The idle Sheave rotate smoothly.

• After having maintenance and have no

abnormalities, apply grease inside adequately

• Timing of change the grease (Refer to “Needle

Bearing (for Idle Sheave) rough standard for

replacethegrease”(P91

)

.

)

Replace the Idle

Sheave.

V ring

• Check visually.

• Check the operating hours

using the CH Meter.

• To have no deformation and crack

• Operating hour must not exceed 200 hours.

Perform the inspection

items of “Guidelines on

VringInspection”(P92).

Periodic Inspection

2

Electric Chain Hoist (ER2) Periodic Inspection

(to be continued)

Bottom Shaft

Loading...

Loading...