DocumentNo.:KE-4025-06 39/50

TypeBSW-0

A compressed heavy-duty spring is packed within the spring case of the

Type BSW actuators. The spring cover may be pushed out and cause

personalinjuryifthetierodusedforfixingthespringcaseisloosenedand

removed. When disassembling the spring case, make sure to follow the

instructionsgiveninthismanual.

■Preparation

Priortodisassemblyofactuators,preparethreadedrods,springpinsandnutsasshowninthetablebelow:

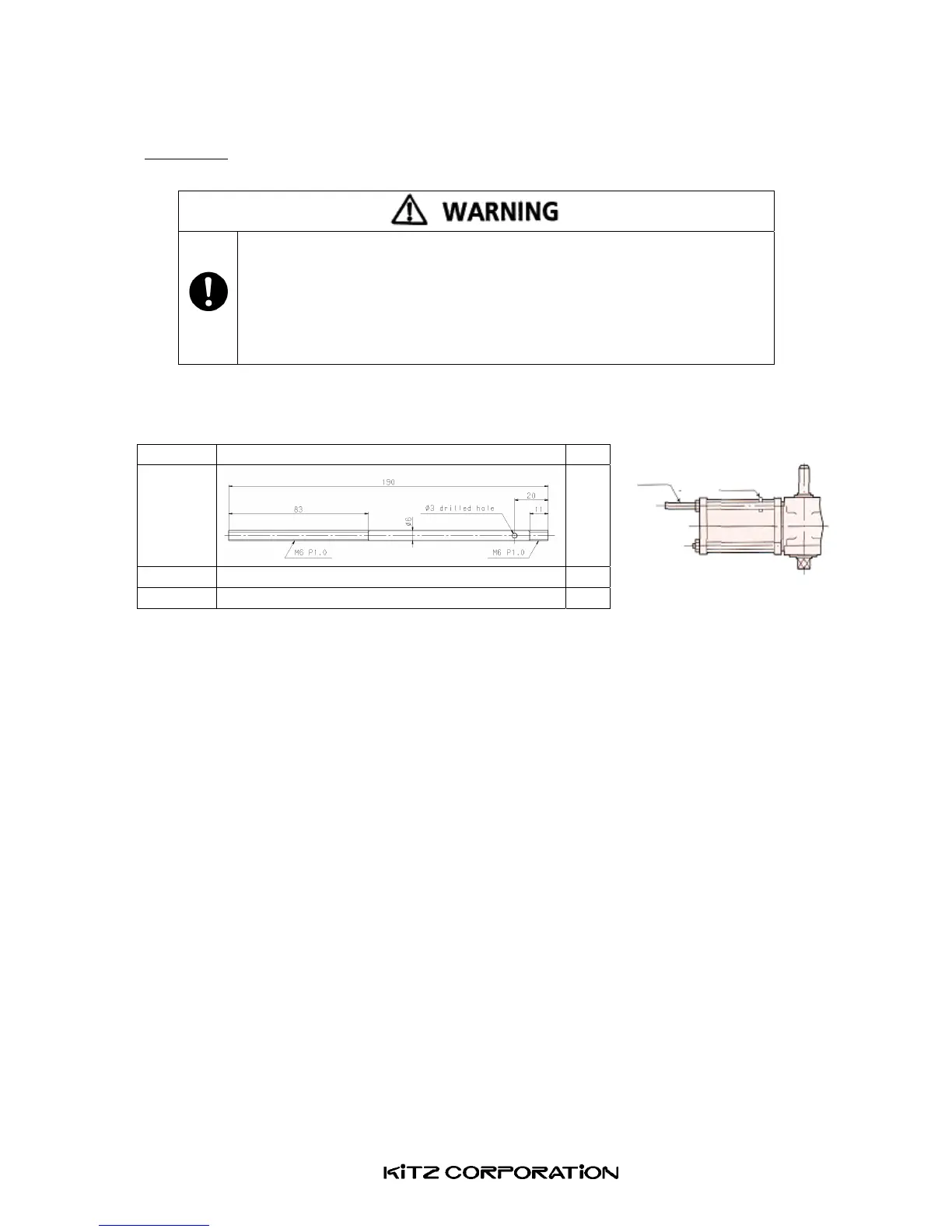

Parts Shapeanddimensions(mm) Qty

Threaded

rod

4

Springpin φ3×16long 4

Nut M6P1.0 4

■Disassembly

1.ReducetheInternalpressuretotheatmosphericlevelandremovetheairtubing.

2.Fullyrotatethemanualhandwheel〈9〉clockwise.

3.Removethehexagonalbolts〈94〉anddisassembletheactuatorfromthebracket〈93〉.

4.Removethehexagonalcapscrew〈10〉,springwasher〈145〉,wheelwasher〈43〉andthehandwheel〈9〉.

5.Removethespringcovernut〈133B〉andstopper〈49〉.

6.Removeoneofthetierod〈56〉andnut〈55〉fromtheactuator.

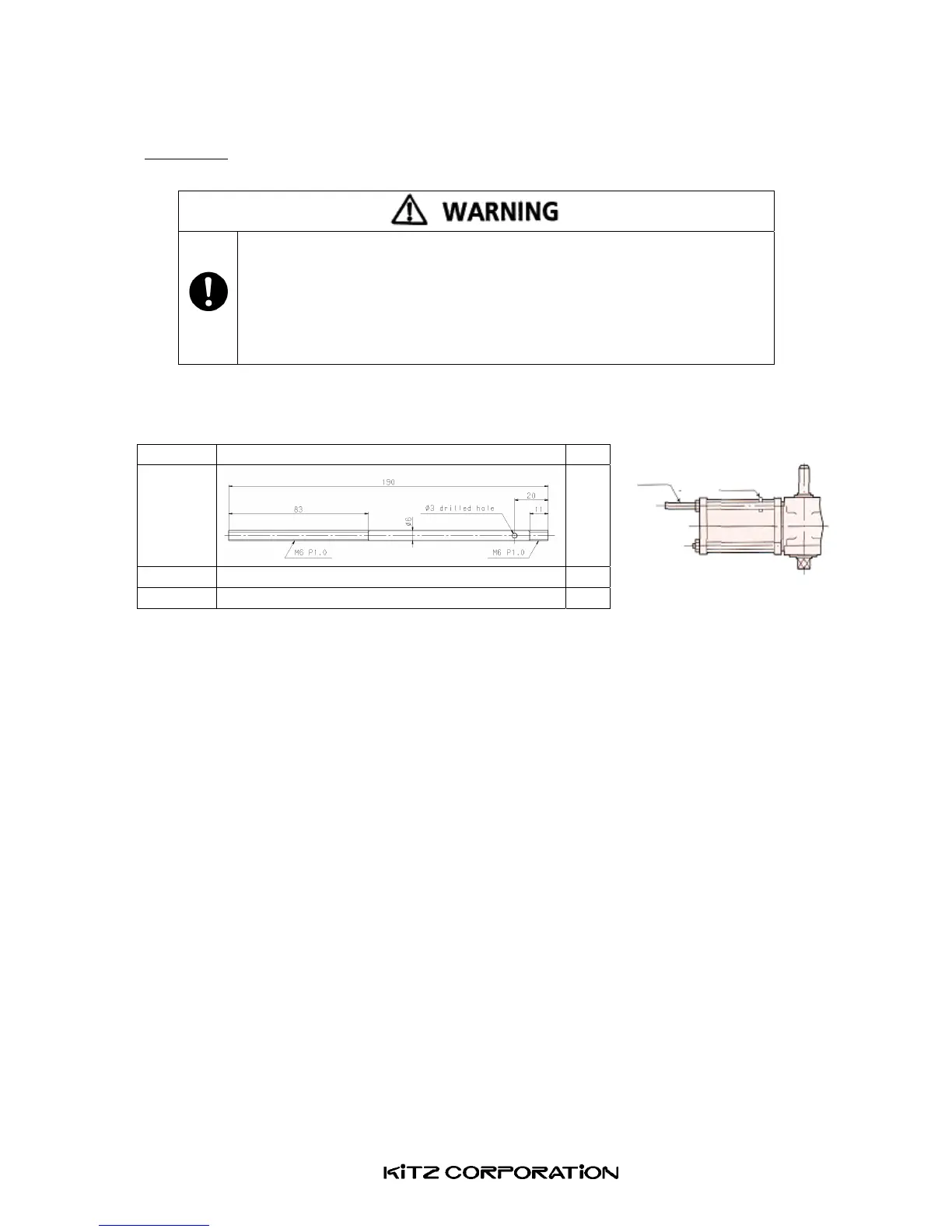

7.Mountoneofthefour threaded rodspreparedin advancewhere theremovedtierodwasmounted,and

secureitonthespringcover〈158〉withanut.Insertaspringpinintoaholedrilledonthethreadedrodfor

securedmounting(Fig.27).

8.Repeatthisworkwithallotherthreadedrods,springpinsandnuts,oneafteranother.

9.Gradually,alternatelyanddiagonallyloosenthenutsandremoveallwhenthespringhaslostitsrecoiling

force.Thenremovethespringcover〈158〉,springcase〈100〉andspring〈109〉.

10.Removeallthreadedrods.

11.Movethespring retainer〈150〉byhandapart from the rod guide〈136B〉tomove the piston〈177〉towards

anotherrodguide〈136A〉.

12.Removethehexagonalcapscrew〈35〉anddisassemblethecylinder〈2〉fromhousing〈1〉,takingcarenotto

scratchtheinternalsurfacecoating.

13.Removethepistonnut〈13a〉andthepiston〈177〉.

Threadedrod

Springpin

Fig.27

Loading...

Loading...