28/31

DocumentNo.:KE-4051-00

1Precautions

Foreignobjectsstucktothevalveseatsmayresultinthegenerationofabnormalnoise.Makesure

toremovetheforeignobjectsimmediatelytopreventvalveseatsandmalfunction.

Abnormalvibrationofthepipelinemaycauseafailureormalfunction.Supportthepipelinefirmly.

① Thevalvebodyandtheactuatoraredesignedlubricantfree.

② Inspecttheproductperiodically,asoftenaspossible,fordefectswhileitisoperating.

1)Fullyclosingandopeningoperation

2)Leakagefromthevalve

3)Vibrationduringoperation

4)Looseboltsandnuts

2DismantlingandReinstallation

DONOTdisassembletheactuatorandthevalvewhilethepowerison.Itmaydamagethe

valveandcauseanaccident.

DONOTputyourfingeroranyobjectinthevalveport.Itmaycauseinjuryordamage.

Reduce the line pressure to atmospheric and remove the residual fluid. Otherwise, an

explosionaccidentmayoccur.

DO NOT disassemble the actuator from the valve for replacement as the valve-actuator

assemblyiscompletedatthefactoryforitsbestperformance.

Wheninstallingathree-wayvalve,checkthattheballportdirection(fluidflowdirection)and

theoperationdirectiononthecontrolcircuitarematched.

Whenremovingtheproductfromthepipe,makesurethatthereisnofluidremainedinthepipe.

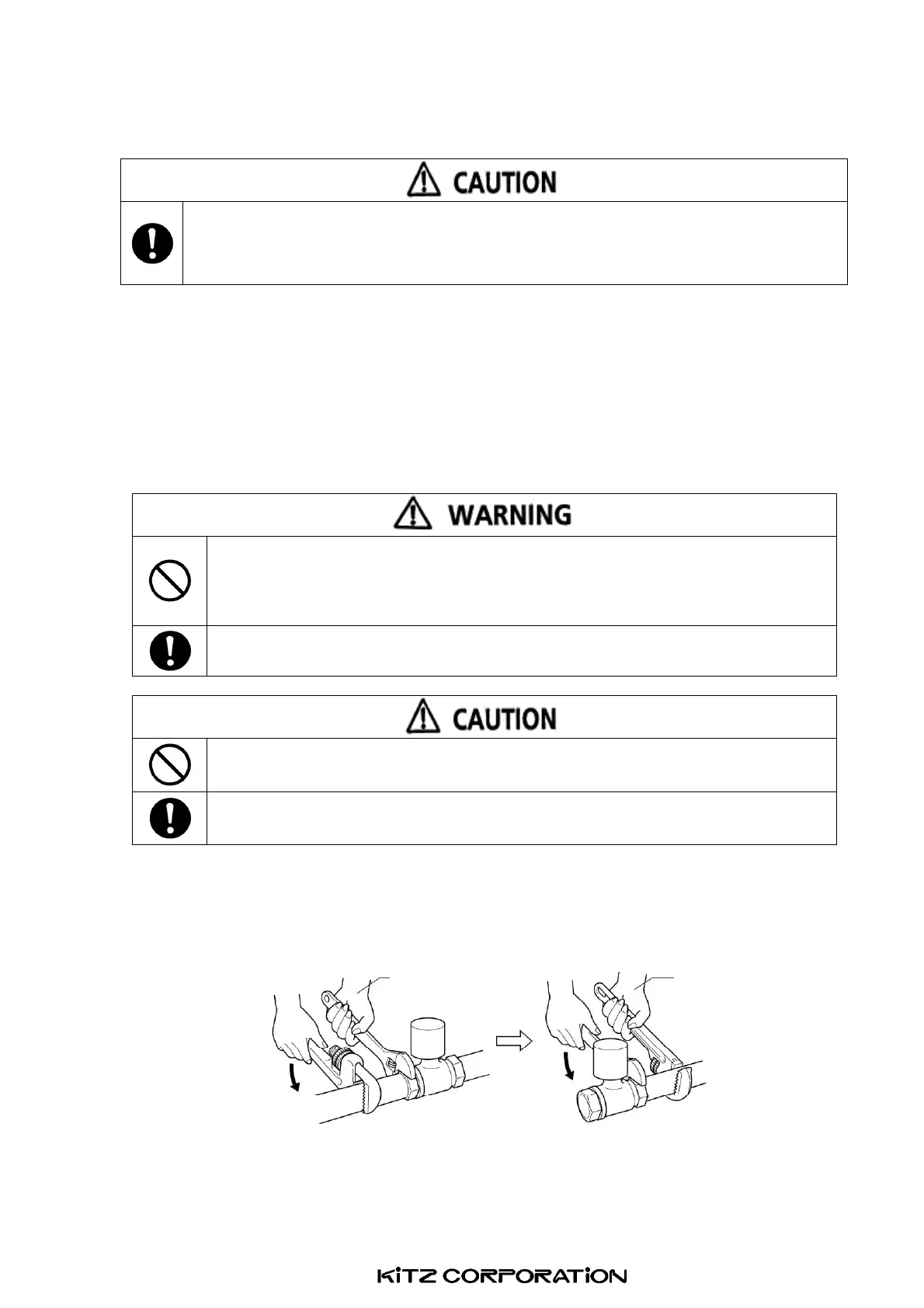

UsetwowrenchesasshowninFig.20.

Fig.20

Whenreinstallingtheproduct,see2.Installationin Ⅲ.Piping.

Hold the valve

irml

sothatthevalvedoe

notrotate.

Holdthepipefirmly so

thatthepipedoesno

rotate.

Loading...

Loading...