DIVA SLIM PELLET BOILER STOVE

29

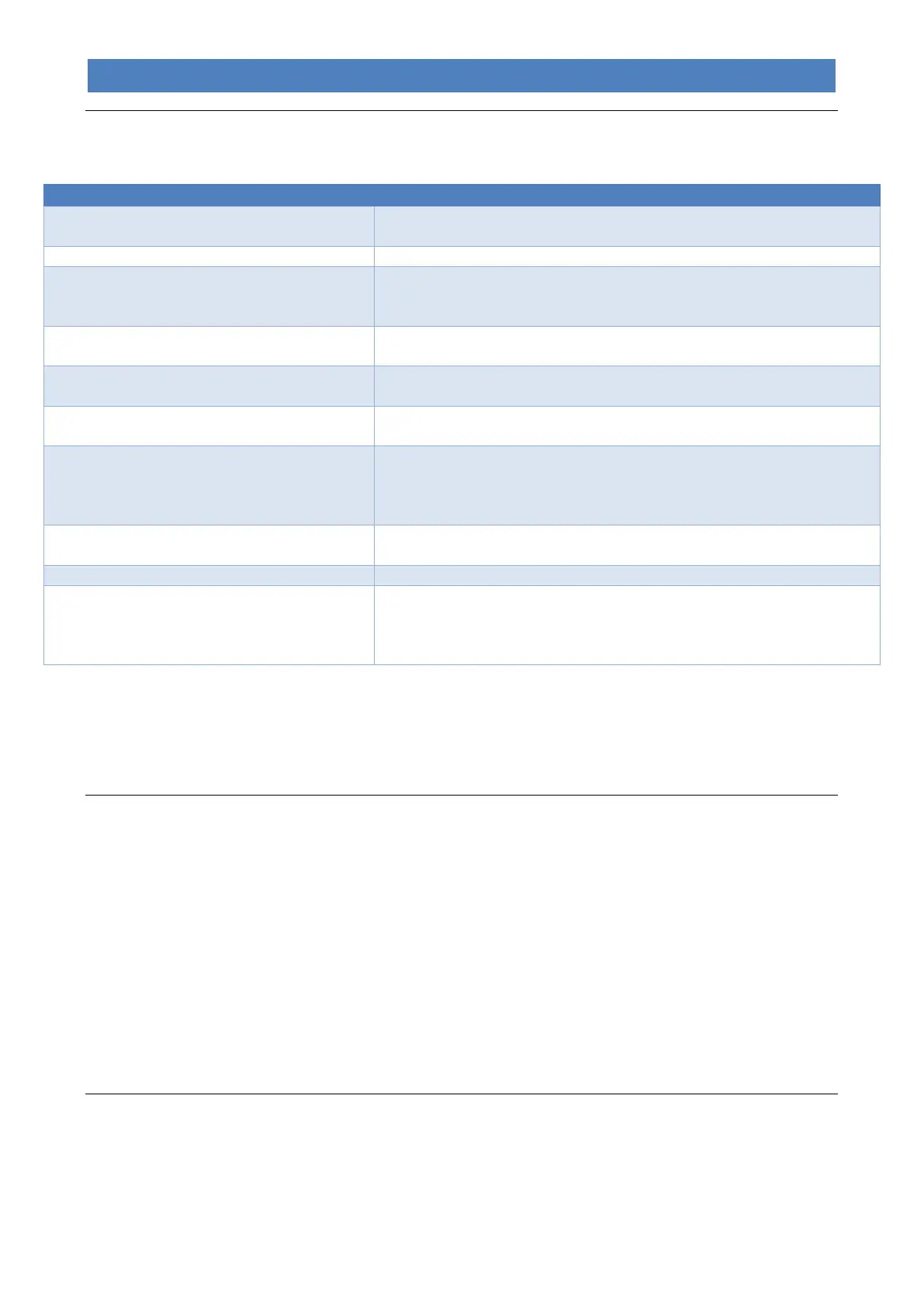

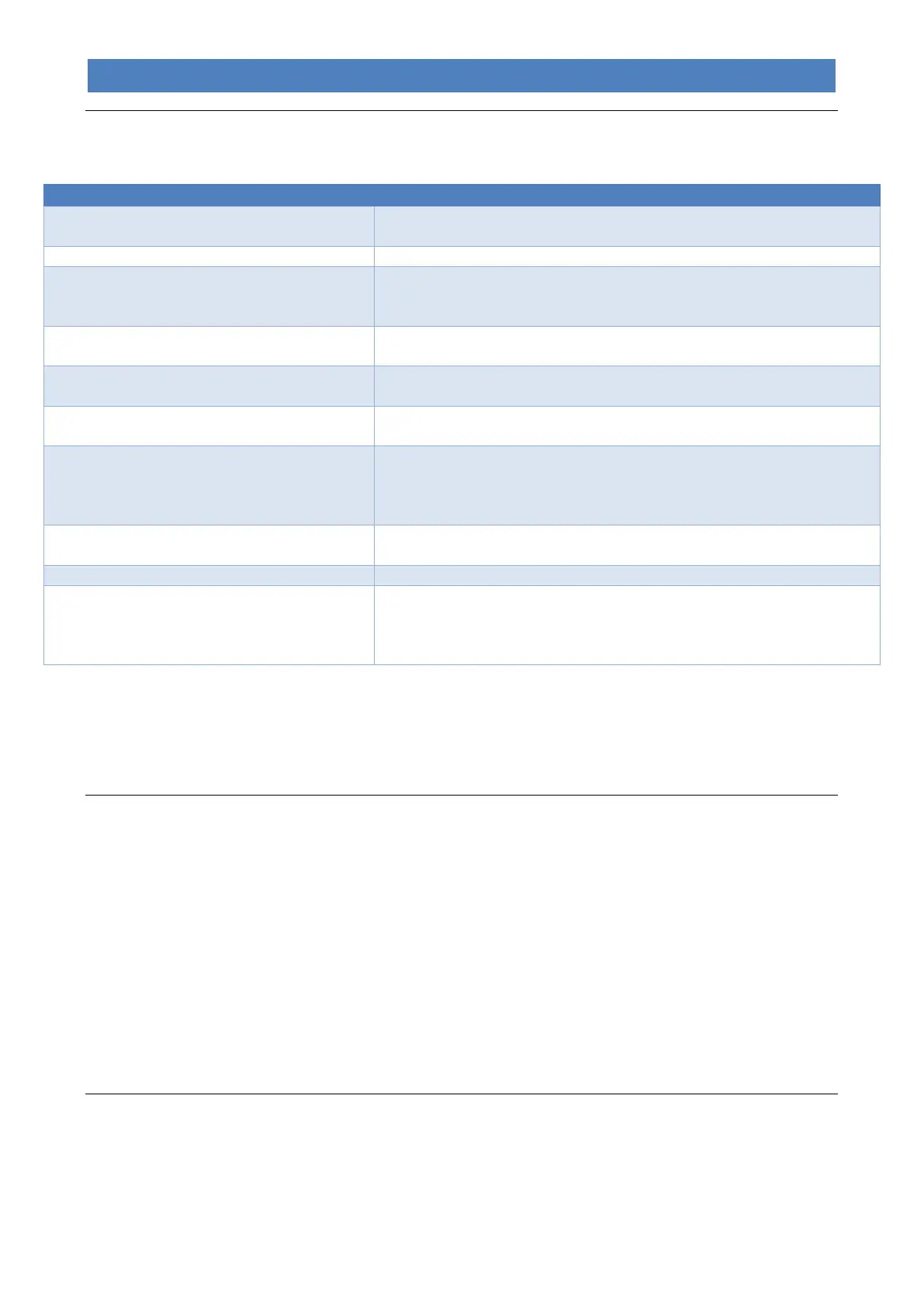

Alarm signals

The following table describes the different alarms which may appear.

AL 1 - BLACK OUT ACTIVE ALARM

Black-out alarm. When power is cut off under determined conditions (see“What

happens if…”)

AL 2 - FLUE GAS PROBE ACTIVE ALARM

Faulty or disconnected flue gas temperature probe.

AL 3 - HOT TEMP ACTIVE ALARM

Flue gas over-temperature. Before displaying the alarm, or when flue gas

maximum temperature is reached (Pr14). the display shows “HOT FLUE

GAS”.

AL 4 - EXTRACTOR-FAILURE ACTIVE ALARM

Faulty flue gas extractor. When the encoder (tachometer) in the extractor

detects an extractor speed equal to 0.

AL 5 - NO IGNITION ACTIVE ALARM

No ignition. When the flue gas minimum temperature (Pr13) is not reached

within the maximum ignition cycle time (Pr01).

AL 6 - NO PELLET ACTIVE ALARM

Sudden shut-down during the work phase. When, during the work phase, the

flue gas temperature drops below the minimum threshold (Pr28).

AL 7 - THERMAL-SAFETY ACTIVE ALARM

Temperature safety device. When the safety thermostat (water over

temperature) or one of the micro switches (contact interrupted) fitted in the fire

door or pellet container door cuts in. If the safety thermostat cuts in the boiler

stove must be manually rearmed.

AL 8 - DEPRESS.-FAILURE ACTIVE ALARM

Poor depression. When the flue gas pressure switch cuts in (contact

interrupted) due to poor draught in the flue pipe.

AL 9 - WATER PROBE ACTIVE ALARM

Faulty or disconnected water temperature probe.

AL c - SF TRIAC ERROR ACTIVE ALARM

Screw feed TRIAC error. When the screw feed gear motor does not stop for at

least 0.2 seconds during the maximum work interval of 8.0 seconds. Before

the alarm is activated a safety relay cuts in and forcibly cuts off the power

supply to the gear motor.

Every alarm causes the appliance to switch-off immediately. The alarm state is reached after the time set on Pr11 (set as

default at 60”) and it can be reset by pressing button 4 for a while.

CLEANING AND MAINTENANCE

Precautions before cleaning

Before carrying out any cleaning or maintenance operations, make sure that:

- the appliance is off and has cooled down completely;

- the ash is completely cold.

- the ash vacuum device used for cleaning is suitable and its filter is in good condition.

Before re-starting the appliance, re-install all previously removed components.

During cleaning operations, use the personal protection devices specified in Directive 89/391/EEC.

The frequency for cleaning depends on the type and quality of pellet burnt; therefore, the indicated times may change.

Any problem affecting the appliance caused by lack of cleaning will not be covered by the warranty. The failure

of these operations could affect the safety of the product.

Cleaning operations may be carried out by the end user, as indicated in the paragraph below.

Routine cleaning

The routine cleaning of the appliance must be done at least every 5 days of operation or after 20 ignition cycles, so as to

always guarantee efficient performance and optimal operation. Please proceed as follows:

Loading...

Loading...