16 of 30 DI-129/11/07.07.15

1.1 ELECTRICAL INSTALLATION

AND WIRING

IMPORTANT!!!

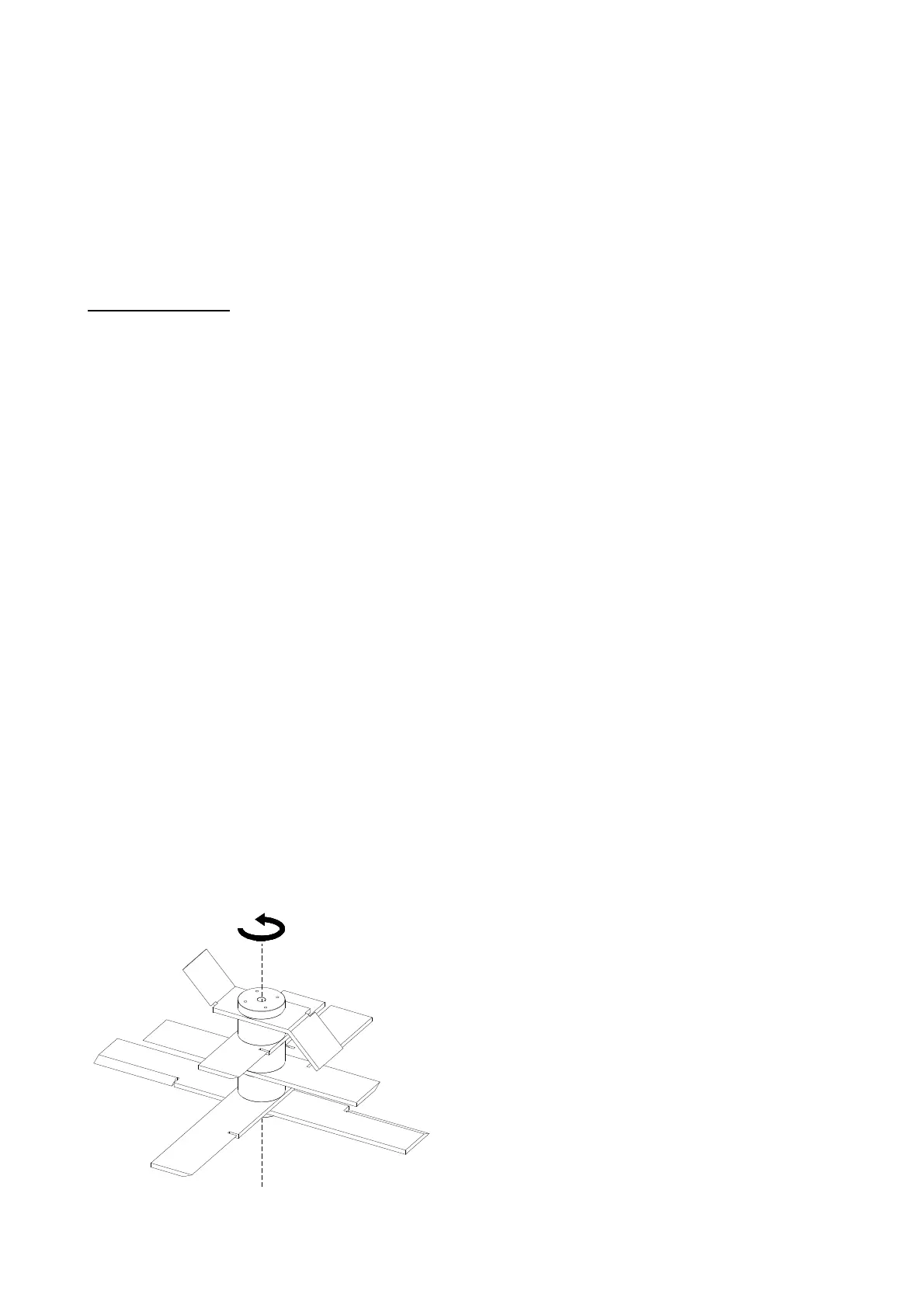

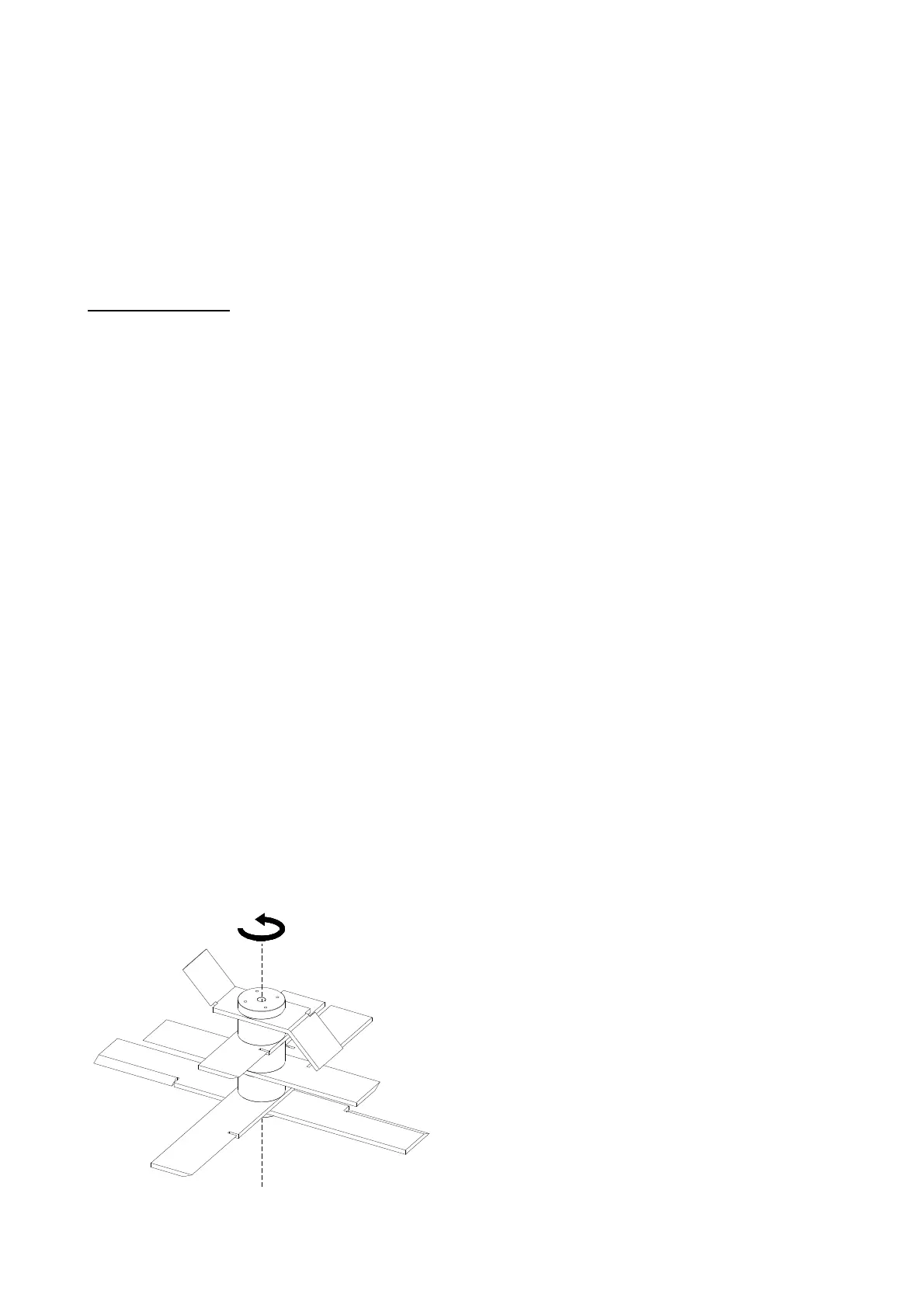

A

fter the machine is connected to the main power

supply it is required to check if blades are rotating in a

COUNTER-CLOCK-WISE DIRECTION when looking

from the top of the blades.

WARNING- DANGER!

These instructions must be followed carefully and in the

exact steps to check the rotation direction:

o Turn the main switch (U) [Sec. E-Fig.2] to “I” (on)

position

o Press the START button (D) [Sec. D-Fig.6] and

after a few seconds

o Press the STOP button (E) [Sec. D-Fig.6]

o Press the emergency button (A) [Sec. D-Fig.6] and

lock it by taking the key out.

o Remove the plastic side cover (M) [Sec. D-Fig.8]

by unlocking it with the standard key delivered with

the Cyclone.

o Open the shredding chamber and check direction

of rotation of the blades while the blades are

coming to a stop.

DO NOT ENTER THE SHREDDING CHAMBER WITH

YOUR HANDS OR ANY PART OF YOUR BODY.

DO NOT TOUCH THE BLADES.

From outside the shredding chamber it is now possible

to check the rotation of the blades of the Cyclone

(which should still be rotating due to the starting

momentum).

If rotation of the blades is clock-wise the electrical

connection to the main power supply must be changed

by switching the position of two of the three phase

wires.

The Turbine/Cyclone system cannot operate if rotation

is clock-wise and no material can be shredded.

Make sure ROTATION OF THE BLADES IS

COUNTER-CLOCK-WISE and make sure that THE

MAIN POWER SUPPLY CAN PROVIDE SUFFICIENT

POWER TO THE CYCLONE AT 208 VOLTS 50 AMPS.

1.2 PLASTIC WASTE BAG [ Sec. D-Fig.9]

The plastic waste bag is a key component of the

Cyclone. The plastic bag is directly integrated in the

Turbine/Cyclone air closed circuit with its main function

to collect the shredded material.

o

The plastic bag is manufactured to withstand the

air pressure of the turbine

o The Plastic bag is located in the rear section of the

machine

o Open rear doors (4) to access the plastic bag.

o The plastic bag must be mounted on the rubber

seal and held in position by the metal ring and

locked.

o The plastic bag can be removed from the machine

through the integrated trolley (Q)

o The weight of the plastic bag when full depends on

the security level (screen) of the machine and on

the type of material which is being shredded.

o Plastic waste bag level is monitored by an

Electronic control system (electronic eyes)

1.3 AIR FILTER BAG

[Sec.F-Fig.10 –11]

The Cyclone is equipped with a dedicated motor which

provides the machine with an air filtration system

designed to maintain clean shredding operation

environment. The filter system collects the dust that

may exit the shredding chamber while shredding

operation is performed.

o The dust is collected in the filter located in a

dedicated housing in the rear of the machine

o To access the filter bag open rear doors (4),

Remove plastic waste bag (R) by the integrated

trolley (Q) (Remove blocking pins (7) [Sec. B-Fig.4]

before removing the trolley with the plastic bag on

it).

o Unlock the filter bag panel (P) with the standard

Cyclone key and open filter bag panel. It is now

possible to check if filter bag is full and needs to be

replaced.

To replace filter bag:

o Remove filter by pulling the cardboard flange of the

filter off the vacuum tube

o Position the new filter bag into its housing and

gently insert and push the cardboard flange

completely onto the vacuum tube.

o Close filter bag panel (P)

Reinstall the plastic bag trolley in its position and fix

it with its blocking pins (7)

o Secure waste bag in place around the cyclone

o Close back doors of the Cyclone

Loading...

Loading...