OPERATION

10/11

11

SLIP CLUTCH - OPERATIONAL CHECK

The slip clutch serves as overall protection for the tractor, driveline, and gearbox. Even though new clutch assemblies

are “run-in” and checked for torque prior to shipment, re-adjustment may be advisable if the clutch has been exposed to

weather for an extended period of time. The clutch facing and plates should be inspected for rust and/or corrosion. After

implement has been stored for 30 days or more, perform the following operational check:

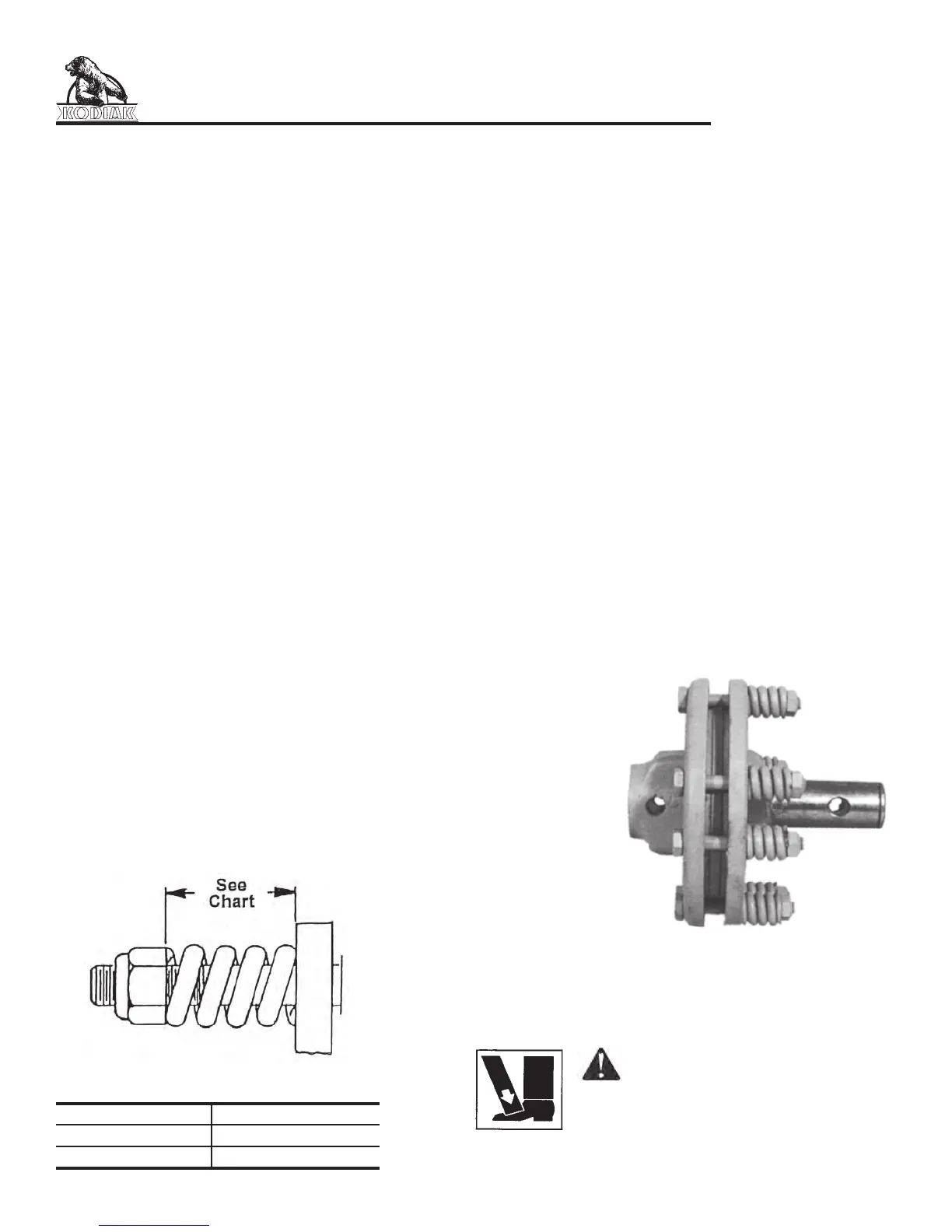

1. Make a trial run in the heaviest operating conditions expected. If the clutch slips noticeably, tighten the 8 adjusting

bolts no more that 1/2 turn between trial runs until the clutch slippage is reduced.

2. Scribe a mark across the clutch facing. When subjected to shock loads, a separation of the marks will assure that

clutch setting is correct. NOTE: Check the clutch periodically during the rst hour of operation for excessive

heat build-up to undetected slippage.

If the clutch is being rebuilt (new facing and/or plates), it is necessary to “run-in” these parts prior to nal adjustment. The

plates should be thoroughly cleaned and free of foreign material, as well as being checked with a straight edge for warp-

ing. Warped plates cannot be adjusted properly and will not hold. To accomplish the “run-in” after assembly, follow the

procedure below:

1. Tighten all adjusting bolts evenly until the clutch cannot be slipped by hand.

2. With the blade carrier locked in a stationary position, operate with the PTO at idling speed (approx. 100 rpm) until

evidence of heating is noted. IMPORTANT: DO NOT ALLOW THE CLUTCH TO OVERHEAT.

3. Discontinue operation and allow the clutch to cool completely. This is very important.

4. After the clutch has cooled, tighten all the adjusting bolts down evenly and proceed with regular clutch adjusting

procedures as described above.

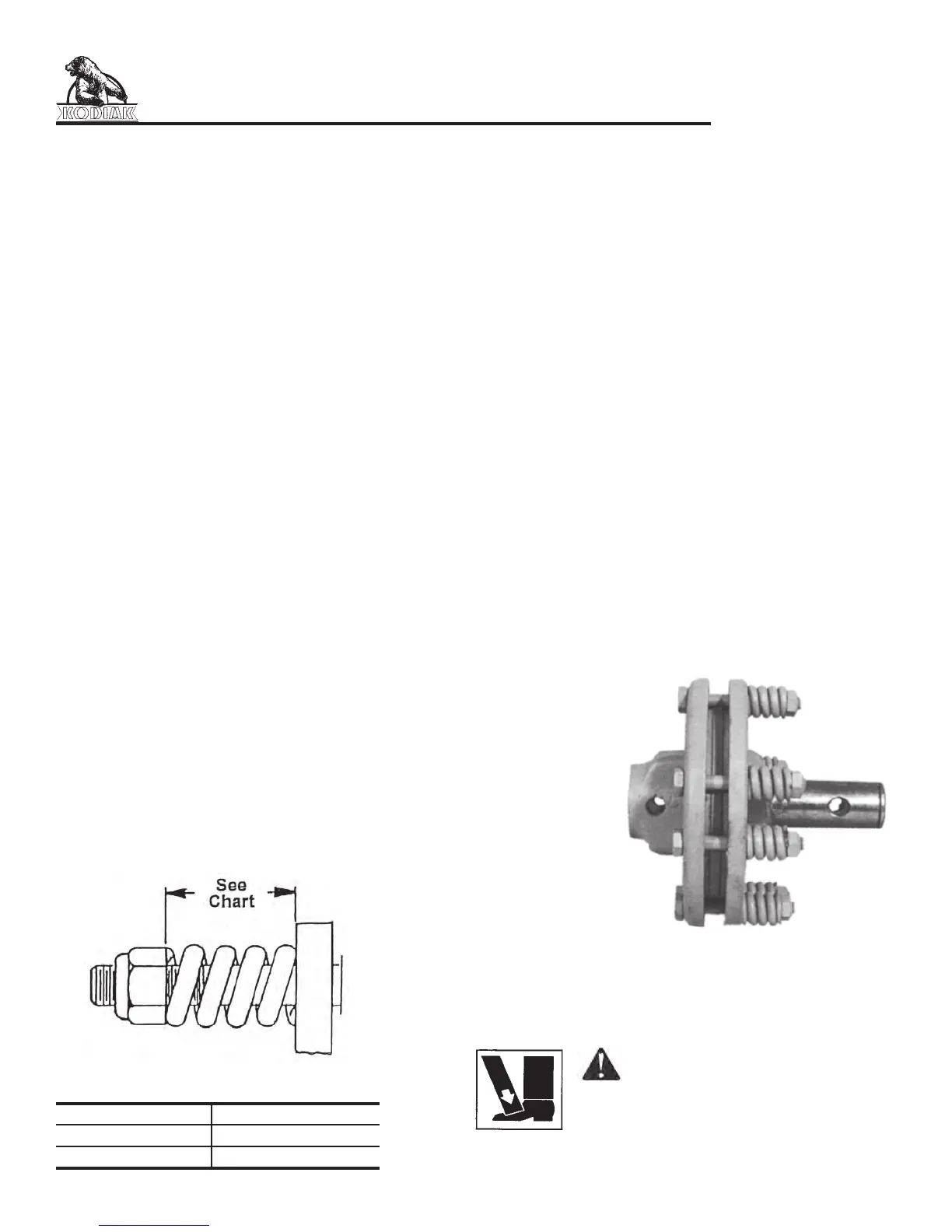

IMPORTANT

DO NOT OVERTIGHTEN NUT AND CAUSE SPRING TO

BECOME SOLID, AS THIS WILL CAUSE SHAFT TO FAIL.

CLUTCH SPRING LENGTH CHART

EG / Comer

1.27” (32.2mm)

1.28” (32.4mm)

Bondioli & Pavesi

1.15” (29.3mm)

1.12” (28.5mm)

SLIP CLUTCH ADJUSTMENT

The slip clutch is factory preset to the correct torque for protecting implement

and tractor. Periodic adjustment is recommended. Should adjustment be

needed, rst check to be sure all spring lengths are the same. Initial spring

length is shown on chart below. If necessary, adjust nut on any spring that is

unequal. Adjust all eight spring retaining nuts 1/3 of a turn (2 ats on a nut)

and check clutch slippage. If further adjustment is necessary, do so in 1/3

turn increments. Adjust only to provide sufcient torque to prevent slippage

under normal conditions. Occasional slippage is normal for drive train protec-

tion. If satisfactory results cannot be obtained, consult your Kodiak dealer.

CAUTION:

USE JACKSTANDS, BLOCKS AND

SAFETY SHOES WHEN PERFORM-

ING MAINTENANCE.

Loading...

Loading...