TP-6196 10/0990 Section 6 Component Testing and Adjustment

Mechanical Governor Sensitivity Adjustment

Note: Often hunting/surging problems thought to be

caused by the governor are actually caused by

engine or carburetor problems. If the generator

set speed is unstable, hunts, or surges, check for

the cause using the procedure in Section 6.9.3

before proceeding.

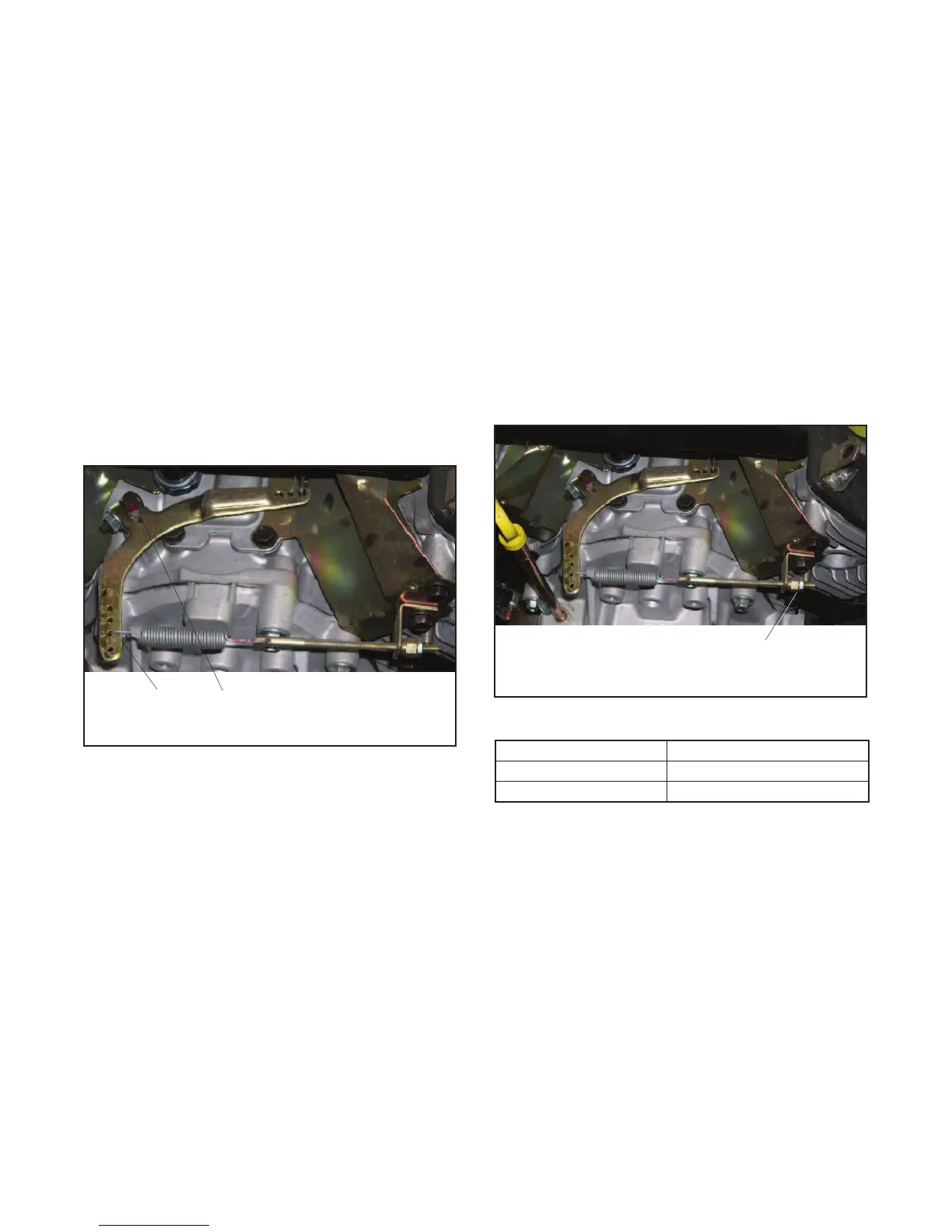

Governor sensitivity is adjusted by repositioning the

governor spring in the holes of the governor lever. If

speed surging occurs with a change in engine load,

decrease the governor sensitivity. If a drop in speed

occurs when normal load is applied, increase the

governor sensitivity. See Figure 6-27 and adjust as

follows:

1. To increase the sensitivity, move the spring closer

to the governor cross shaft.

2. To decrease the sensitivity, move the spring away

from the governor cross shaft.

#

1. Governor lever

2. Cross shaft

1

2

photo5005

Figure 6-27 Governor Sensitivity Adjustment

Engine Speed (Frequency) Adjustment,

Mechanical Governor

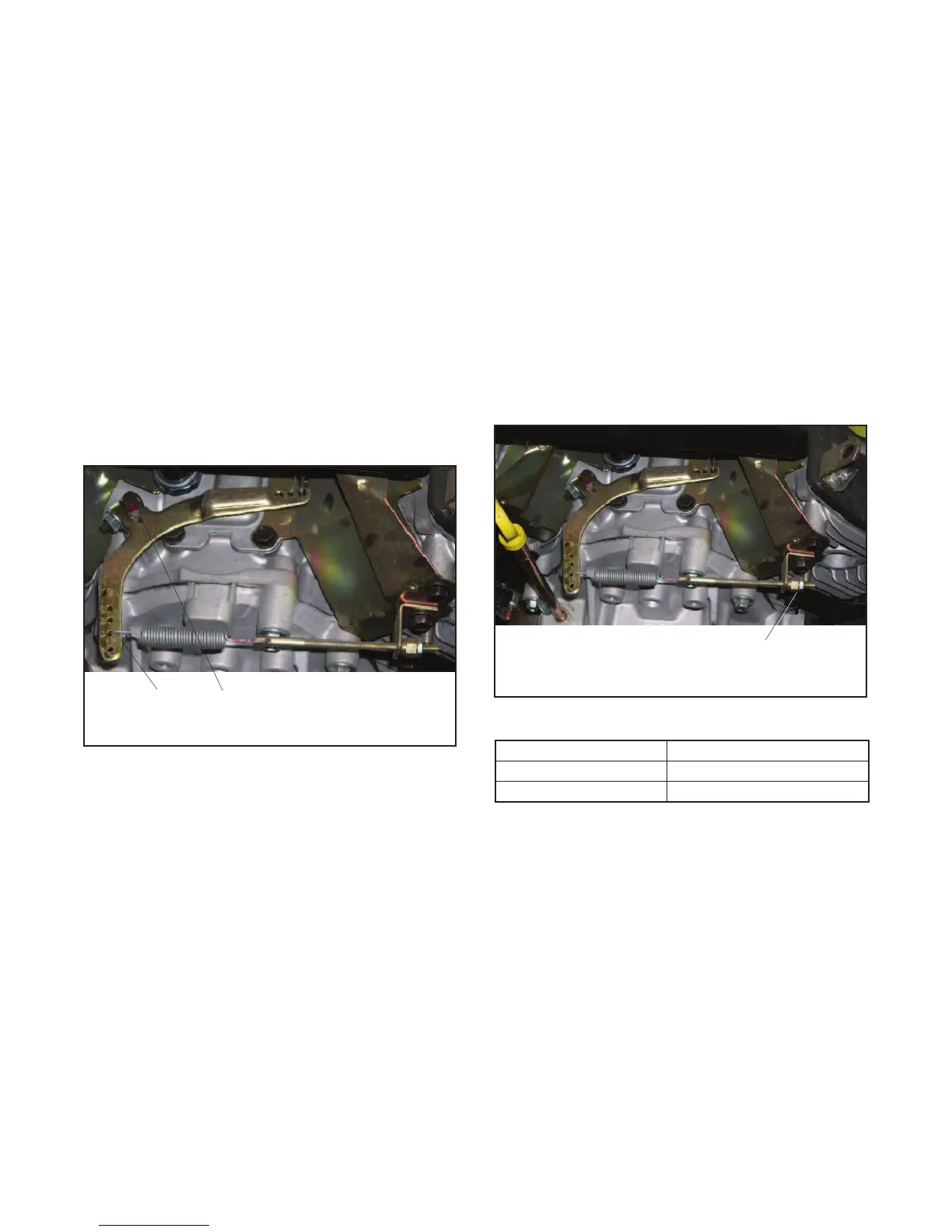

Use the adjusting nut shown in Figure 6-28 to adjust the

engine speed, if necessary. Recommended engine

speeds with no load and full load are shown in

Figure 6-29.

1. With the engine running, loosen the lock nut.

2. If the engine is running too slow (frequency is low),

turn the adjusting nut clockwise to increase the

speed.

3. If the engine is running too fast, turn the adjusting

nut counterclockwise, backing the nut out and

decreasing the speed.

4. Verify that the engine speed is correct and tighten

the locknut.

1

photo5005

1. Speed adjusting nut and lock nut

Figure 6-28 Engine Speed Adjustment

Generator Set Load Engine Speed

No Load 3780 RPM (63 Hz)

Full Load 3600 RPM (60 Hz)

Figure 6-29 Recommended Engine Speed

Loading...

Loading...