TP-5393 9/933-10 Scheduled Maintenance

LP Carburetor Adjustments

Main Fuel Mixture

For preliminary setting turn the MAIN FUEL valve in a

clockwise direction until it bottoms lightly (do not force),

then back out 1 turn. With the engine thoroughly

warmedupand runningatratedrpmunderfullload,turn

MAIN FUEL valve in until the engine slows down (lean

setting) then turn valve out until the engine regains full

speed (about 1/8 turn). When properly adjusted, the

engine will operate with steady governor action.

Improper adjustment (rich setting) causes improper

operationofthevaporizerandexcessfuelconsumption.

Idle Fuel Mixture

The idle system functions only at part- and no-load

conditions. For this reason, the idle setting has only a

momentary effect. To adjust, stop the engine and then

turntheIDLEFUELscrewallthewayin(clockwise)then

back out 1/4 turn. Adjust for proper no load operation.

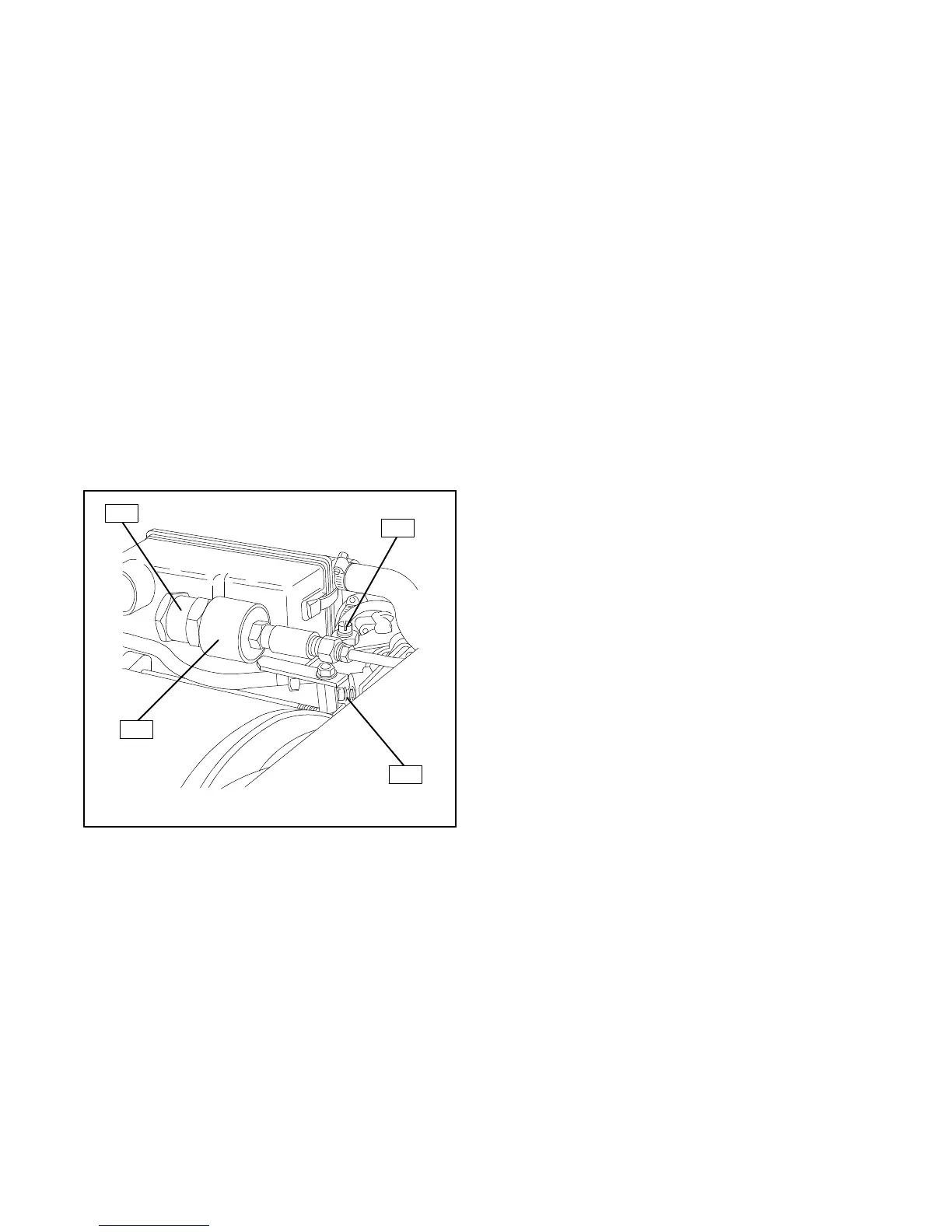

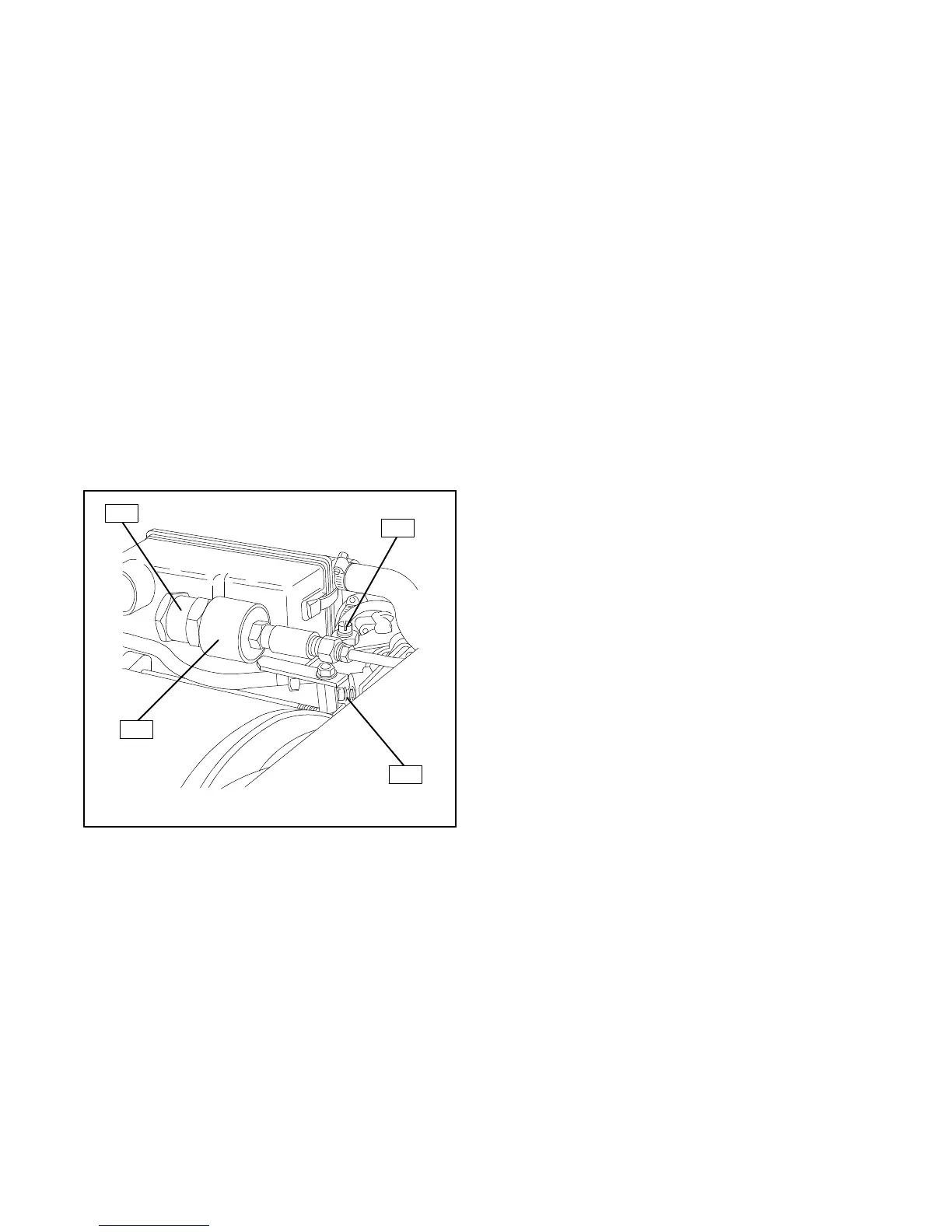

1-917

2

3

4

1

1. Fuel Valve

2. Fuel Filter

3. Main Fuel Adjustment

4. Idle Fuel Adjustment

Figure 3-12. LP Gas Carburetor Adjustments and

LP Gas Fuel Valve Assembly

Fuel Valve and Filter—LP Liquid

The LP fuel valve contains a replaceable filter which

should be inspected yearly or after every 100 hours of

operation. Normally,the filterrequiresreplacementonly

after accumulation of filtered debris restricts fuel flow to

the regulator/vaporizer. Rough generator operation

and/or the presence of frost on the fuel valve outer

surface indicates filter replacement is necessary.

AssemblyoftheLPgasfuelvalveandlocationofthefuel

filter is shown in Figure 3-12.

Loading...

Loading...