4 — PROGRAMMABLE PARAMETERS

pg. 127

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

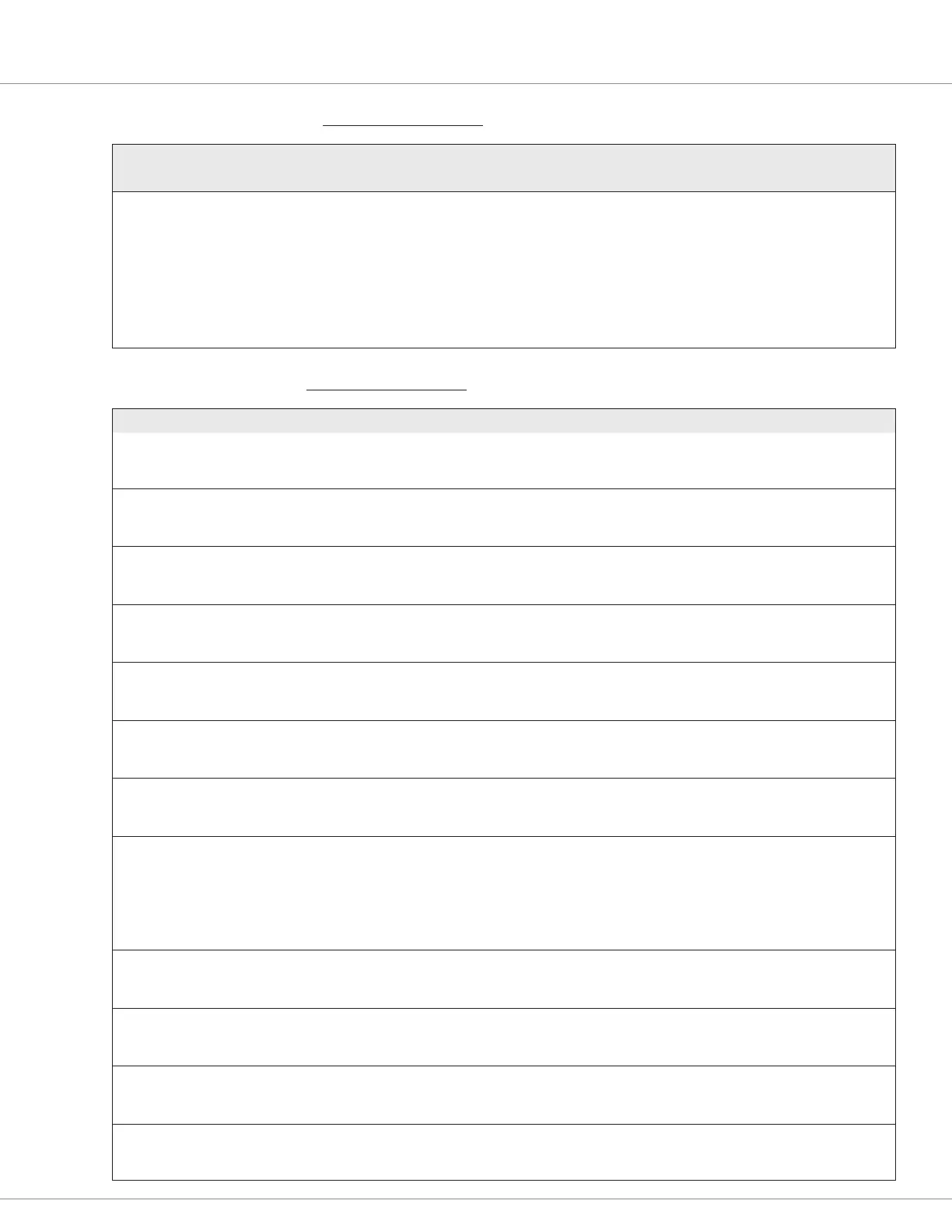

CONTROLLER SETUP — EXTERNAL SUPPLIES MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

5V Output Enable

Ext_5V_Output_Enable

0x36A8 0x00

On/Off

On/Off

On Enables the 5V Power Supply Output.

12V Output Enable

Ext_12V_Output_Enable

0x36A7 0x00

On/Off

On/Off

Off Enables the 12V Power Supply Output.

5V Measured

External_5V_Supply

0x36AA 0x00

0.00 – 100.00V

0 – 10000

Read Only Voltage at the +5V output.

5V Supplied Current

Ext_5V_Current

0x36AE 0x00

0 – 200 mA

0 – 200

Read Only Current (mA) at the +5V output.

The limit is based upon the controller model.

12V Measured

External_12V_Supply

0x36AB 0x00

0.00 – 100.00V

0 – 10000

Read Only Voltage at the +12V output.

12V Supplied Current

Ext_12V_Current

0x36AF 0x00

0 – 200 mA

0 – 200

Read Only Current (mA) at the +12V output.

The limit is based upon the controller model.

Total Supplied Current

Ext_Supply_Current_mA

0x36A9 0x00

0 – 200 mA

0 – 200

Read Only Total current from both the 5V and 12V supplies.

Maximum is 200 mA.

Encoder Power Source

Encoder_Power_Source

0x36A0 0x00

Enumerated

0 - 2

0 = None

1 = 5V

2 = 12V

5V Sets the Power Supply Source to the 5 or 12 volts for the Encoder.

Use this parameter to determine which supply voltage, if any, is

used to issue an encoder fault if the supply itself faults.

5V Supply Min

Ext_5v_Supply_Min

0x36A4 0x00

0 – 200 mA 0 mA Sets the lower threshold of the current of the 5V external supply.

Current below this threshold will generate a fault (Ext_5V_Supply_

Failure_Active 0x2531) that can be read by VCL.

5V Supply Max

Ext_5v_Supply_Max

0x36A3 0x00

0 – 100 mA 100 mA Sets the upper threshold of the current of the 5V external supply.

Current above this threshold will generate a fault (Ext_5V_Supply_

Failure_Active 0x2531) that can be read by VCL.

12V Supply Min

Ext_12v_Supply_Min

0x36A6 0x00

0 – 200 mA 0 mA Sets the lower threshold of the current of the 12V external supply.

Current below this threshold will generate a fault (Ext_12V_Supply_

Failure_Active 0x2532) that can be read by VCL.

12V Supply Max

Ext_12v_Supply_Max

0x36A5 0x00

0 – 100 mA 100 mA Sets the upper threshold of the current of the 12V external supply.

Current above this threshold will generate a fault (Ext_12V_

Supply_Failure_Active 0x2532) that can be read by VCL.

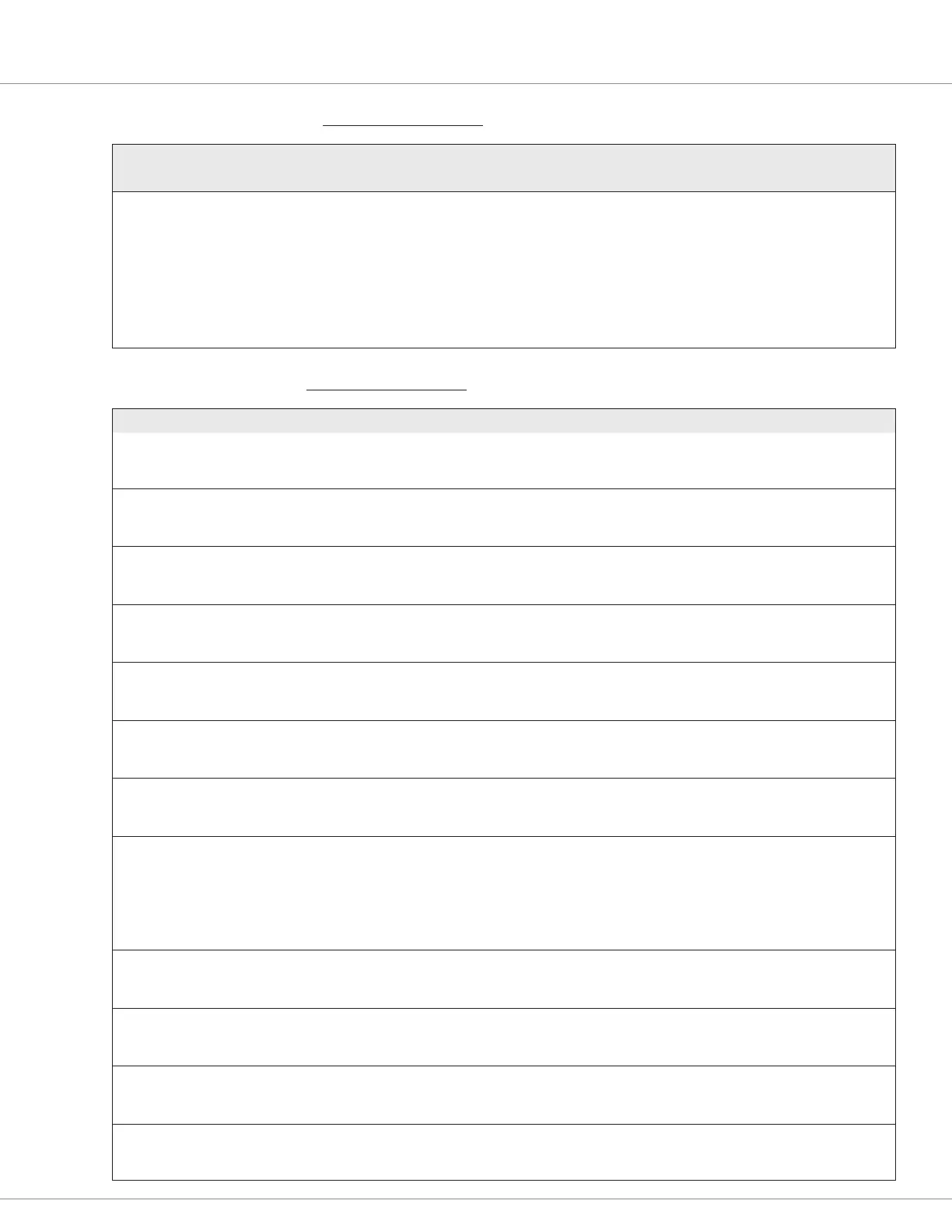

CONTROLLER SETUP — OUTPUTS MENU, cont’d

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

Driver 2–7

Driver X Checks Enable

Driver_X_Checks

Enumeration

0 – 2

Checks Off See Driver 1.

X = 2–7.

Note: Drivers 6 and 7 do not apply to the 23-pin controllers.

Driver_2_Checks : 0x341C 0x00

Driver_3_Checks : 0x341D 0x00

Driver_4_Checks : 0x341E 0x00

Driver_5_Checks : 0x341F 0x00

Driver_6_Checks : 0x3420 0x00

Driver_7_Checks : 0x3421 0x00

Loading...

Loading...