6 — COMMISSIONING

pg. 171

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

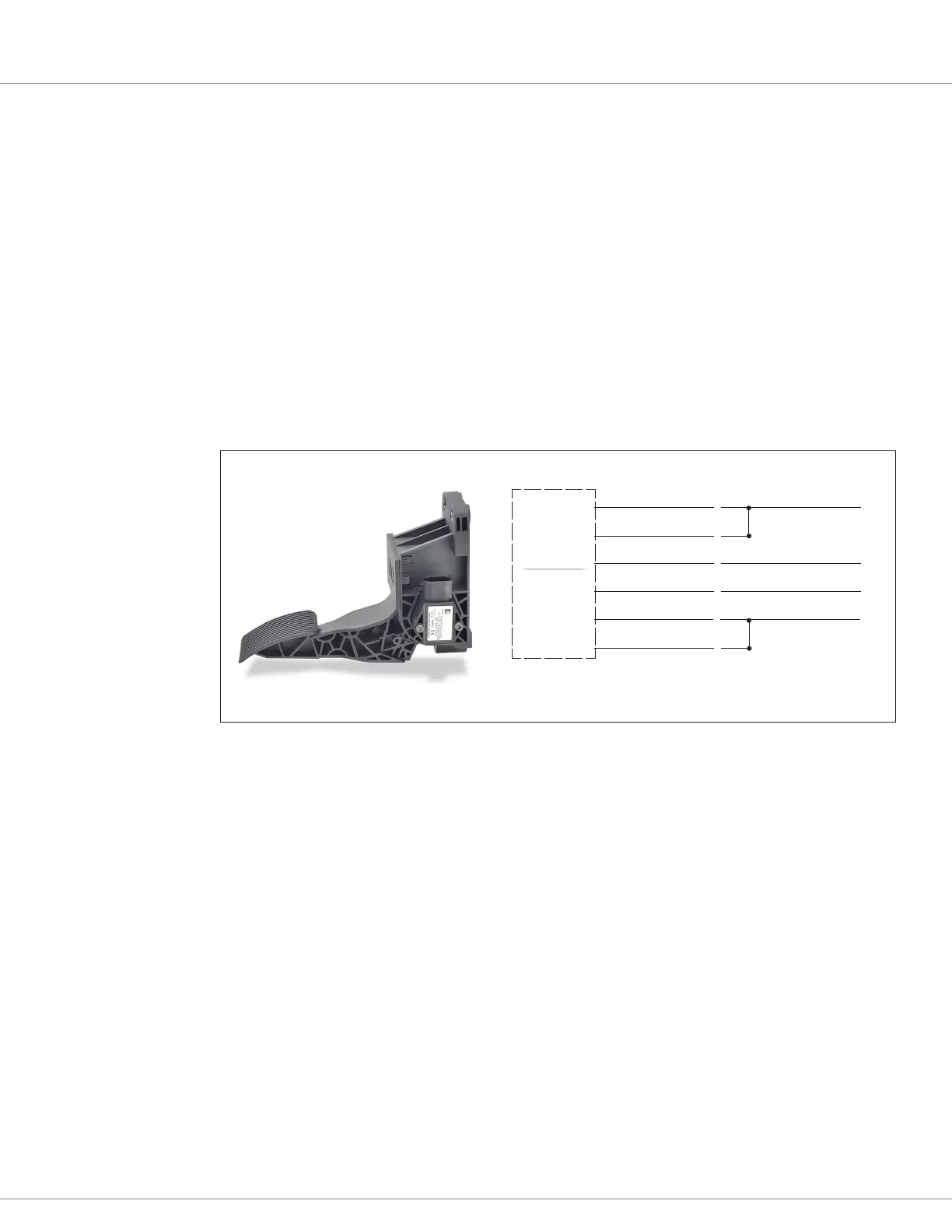

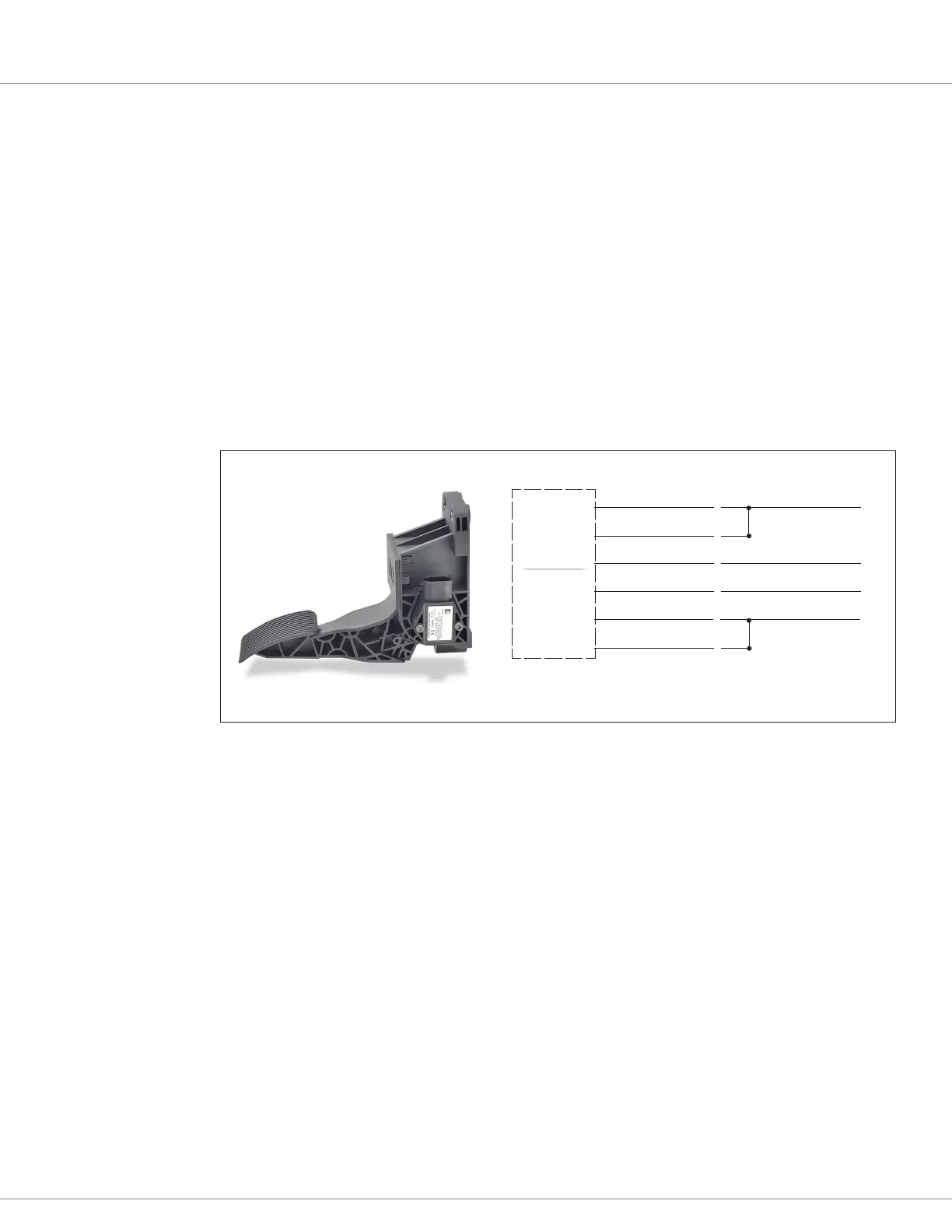

Hall-eect voltage throttles

e Curtis FP Series of electronic throttles oers multiple pedal angles and mounting congurations

(oor, suspended, ush) with 0–5 Volt operation and an Idle Validation Switch (IVS). e IVS will

connect to an assigned analog input (e.g., pin 16). See Figure 38 (35-pin controller basis).

e Curtis ET-XXX (e.g., ET-126) electronic throttle is typically a drive throttle (as illustrated in

Figure 39). When used in Class III tiller handles or twist-throttle grips, it oers symmetrical throttle

response in both the forward and reverse directions of the twist-grip/ippers (i.e., CW and CCW

rotation). Based upon rotation it switches the forward or reverse switches to KSI and thus provides the

directional switches within the throttle assembly. It is a wigwag type throttle, which when released,

returns the throttle to neutral for convenience and safety. Other, similar third party wigwag throttles

follow the same setup process.

e ET-XXX voltage throttles contain no built-in fault detection, or a throttle validation signal. It is

the responsibility of the OEM to provide appropriate throttle fault detection.

THROTTLE SENSOR OUTPUT (0.5 –4.5V)

IVS OUTPUT (0.75V [5-0V])

HALL-EFFECT

THROTTLE

S E NSO R

I/O Ground (pin 7)

Voltage (analog 1) input (pin 16)

(1) Sensor +5V supply

(2) Ground

(3) IVS Signal (voltage)

(4) Throttle Signal (voltage)

(5) IVS Ground

(6) IVS +5V supply

>>

>>

>>

>>

>>

>>

+5V (pin 26)

Voltage (analog) input (pin TBD)

IDLE-VALIDATION

SWITCH

Figure 38

Curtis FP-SCV-0022

Hall-eect rottle

Voltage rottle setup

Wire the voltage throttle as illustrated in the options shown in Figures 38 and 39. With the throttle

connected and powered, set the Low and High parameters based upon the observed input Voltage

(analog_input_volts_1) while moving the throttle throughout its physical range (stroke). ese

parameters set the range for 0% (Low) and 100% (High) throttle. Inputs below and above these set

points will declare a fault. e Percent (Analog_Input_Percent_1) monitor variable is repeated as

rottle Input (rottle_Pot_Percent) in the Application Setup » rottle menu. Use either of these

variables as feedback when adjusting the potentiometer throttle’s Forward & Reverse Min/Max

Input parameters (described below).

For voltage throttles with an idle validation switch or additional voltage outputs, program these

signals as per their type using the controller’s available switch or analog inputs. Reference the

wiring diagrams and Tables 8 and 9 for these available switch and analog inputs. Be sure to include

these additional signals in a VCL program as the means to integrate such throttle validation signals

into the controller application.

Note: e pin numbers in Figures 36–39 are on the 35-pin controller basis.

Quick Links:

Table 8 (Switch Inputs) p.20

Table 9 (Analog Inputs) p.22

Loading...

Loading...