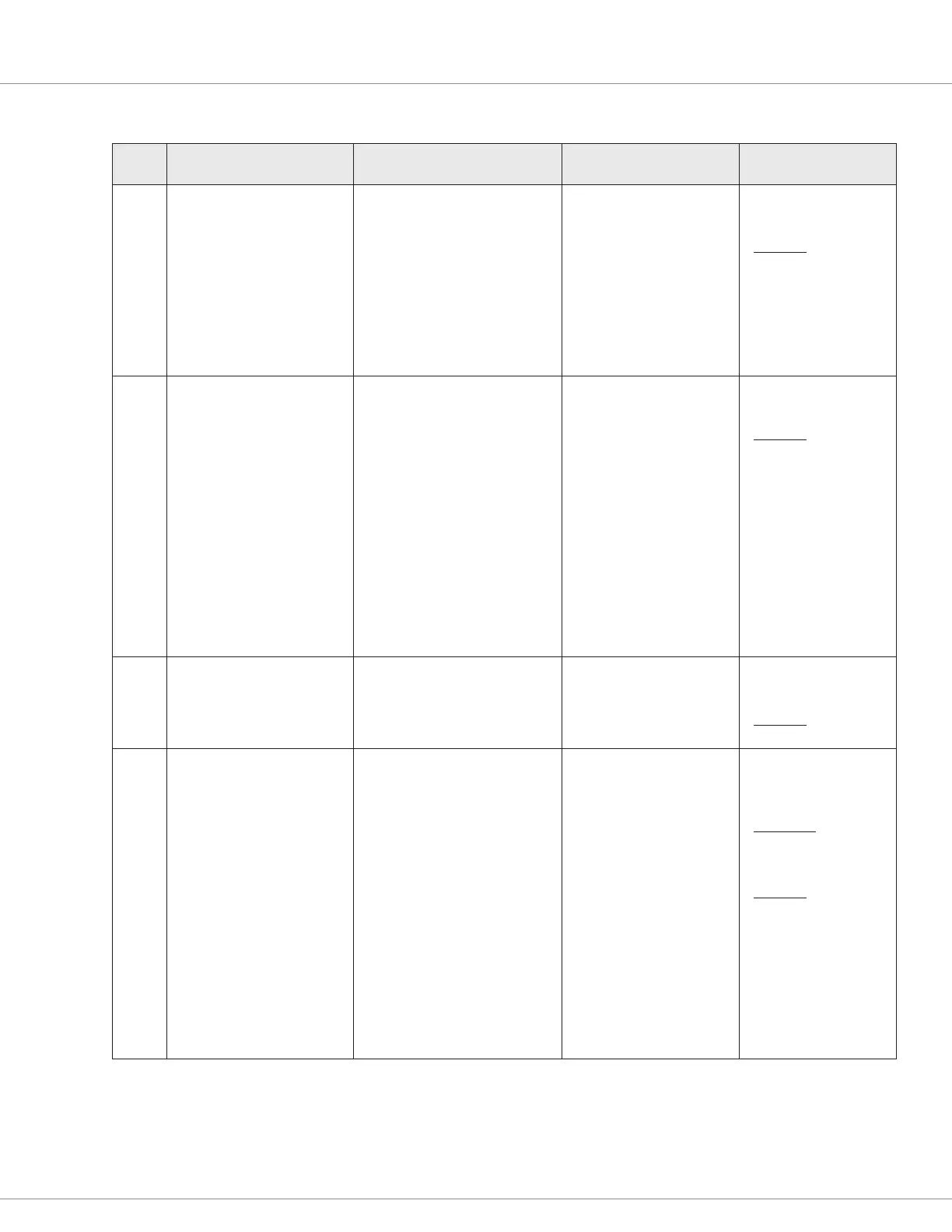

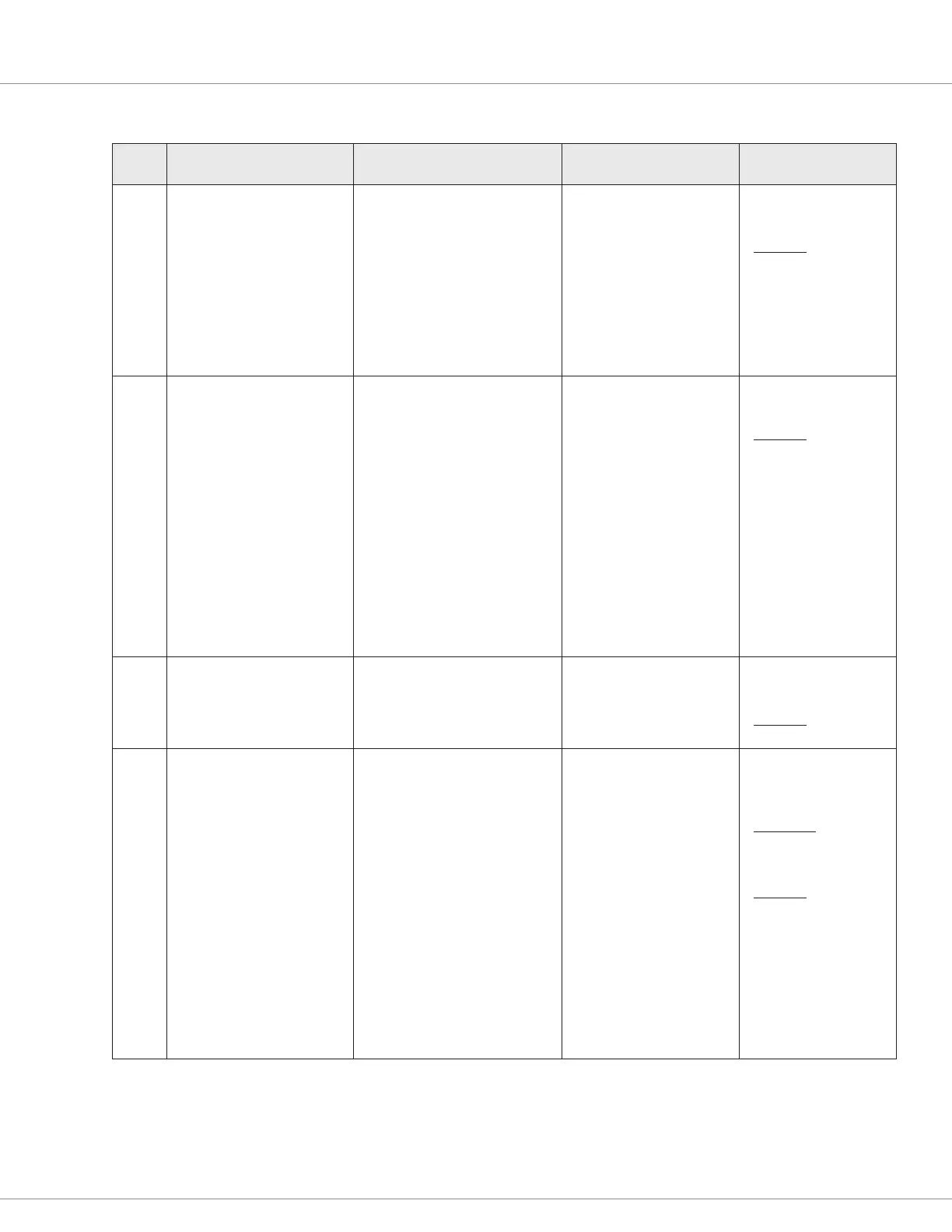

7 — DIAGNOSTICS AND TROUBLESHOOTING

pg. 213

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

FLASH

CODE

FAULT NAME

(Curtis Integrated Toolkit™)

POSSIBLE CAUSES SET/CLEAR CONDITIONS FAULT ACTIONS

1-12

0x1C

OS General 2

OS_General_2

0x210A

Fault Type(s):

(<100) Internal Fault. Contact

Curtis support.

(>100) An ill-formed or

corrupted application

package was loaded

into controller.

1. (<100) Internal Fault.

2. (>100) CIT version is too old to fully

support the FOS version.

Set: Program execution within

the controller encountered a

serious problem and could

not recover.

Clear:

(<100) Internal Fault.

(>100) Update CIT version,

re-package the project,

and re-ash the

application package.

NO ACTION

(controller is not operable)

Dual Drive

Same, both motors

1-13

0x1D

Reset Rejected

Reset_Rejected

0x2110

Fault Type(s): 1

This occurs if a controller is

commanded to reset while controlling

a PMAC motor that is not stationary.

Examples of resets include sending

an NMT reset or calling reset_

controller() in VCL.

Note, the controller will NOT reset

when safe unless the NMT is resent

or reset_controller() is called again.

If legacy brownout is set to off,

the user may see this fault if the

controller is turned off and on again

at an unsafe time, but in this instance

the controller will reset as soon as

it is safe to do so. Consult Curtis

Support for further assistance using

non legacy brownout.

Set: A reset was called at a

time unsafe for the controller.

Clear: Cycle KSI.

ShutdownInterlock

ShutdownThrottle

Dual Drive

Same, both motors

1-14

0x1E

Motor Short

Motor_Short

0x210E

Fault Type(s): 1

Check Motor Type and Parameters.

See the PMAC considerations.

Indicates whether the fault is

presently active or not.

Set: The motor was shorted to

avoid dangerous voltage levels.

Clear: Reset controller.

NO ACTION

(controller is not operable)

Dual Drive

Same, both motors

2-2

0x22

Controller Overtemp Cutback

Controler_Overtemp_Cutback

0x2140

Fault Type(s):

1 = Controller heatsink high

temperature (affecting AC

phases)

2 = Controller heatsink high

temperature (affecting

pump phase)

3 = Capacitor bank high

temperature

4 = AC phase FET high

temperature

5 = Pump phase FET high

temperature

6 = Low Frequency single

phase high temperature.

1. Controller is operating in an

extreme environment.

2. Excessive load on vehicle.

3. Improper mounting of

controller which is preventing

controller cooling.

4. Controller is performance-limited

at this temperature.

5. See Programmer » System Monitor

menu » Controller » Temperature.

Set: Controller’s heatsink

temperature exceeded 85°C.

Clear: Bring heatsink

temperature below 85°C.

Reduced drive torque.

Reduced regen-braking

torque.

Fault Action:

None, unless a fault action

is programmed in VCL.

Dual Drive

This Motor:

TrimDisable

Other Motor:

TrimDisable

Table 24 Fault Code Troubleshooting Chart, cont’d

Loading...

Loading...