4 — PROGRAMMABLE PARAMETERS

Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022 Return to TOC

pg. 70

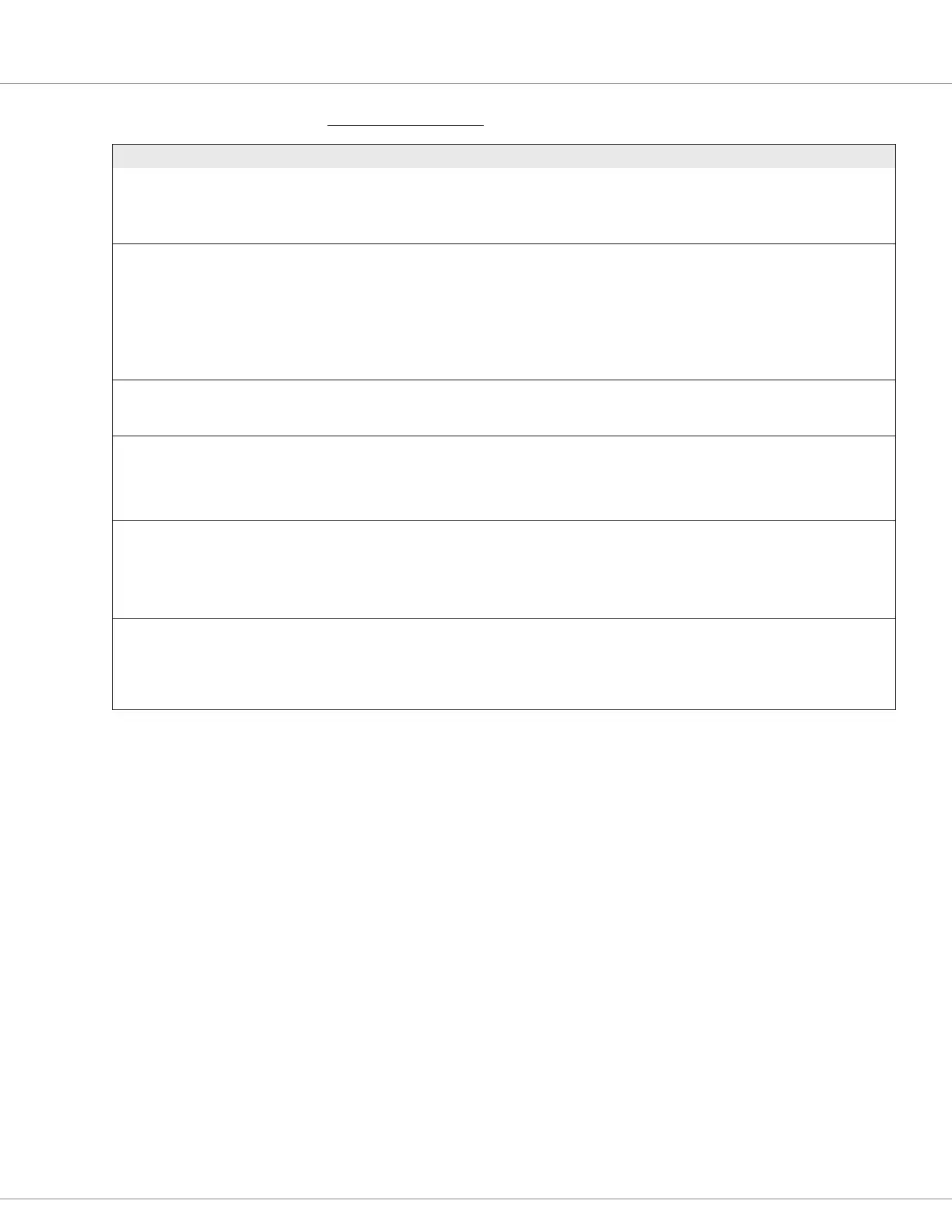

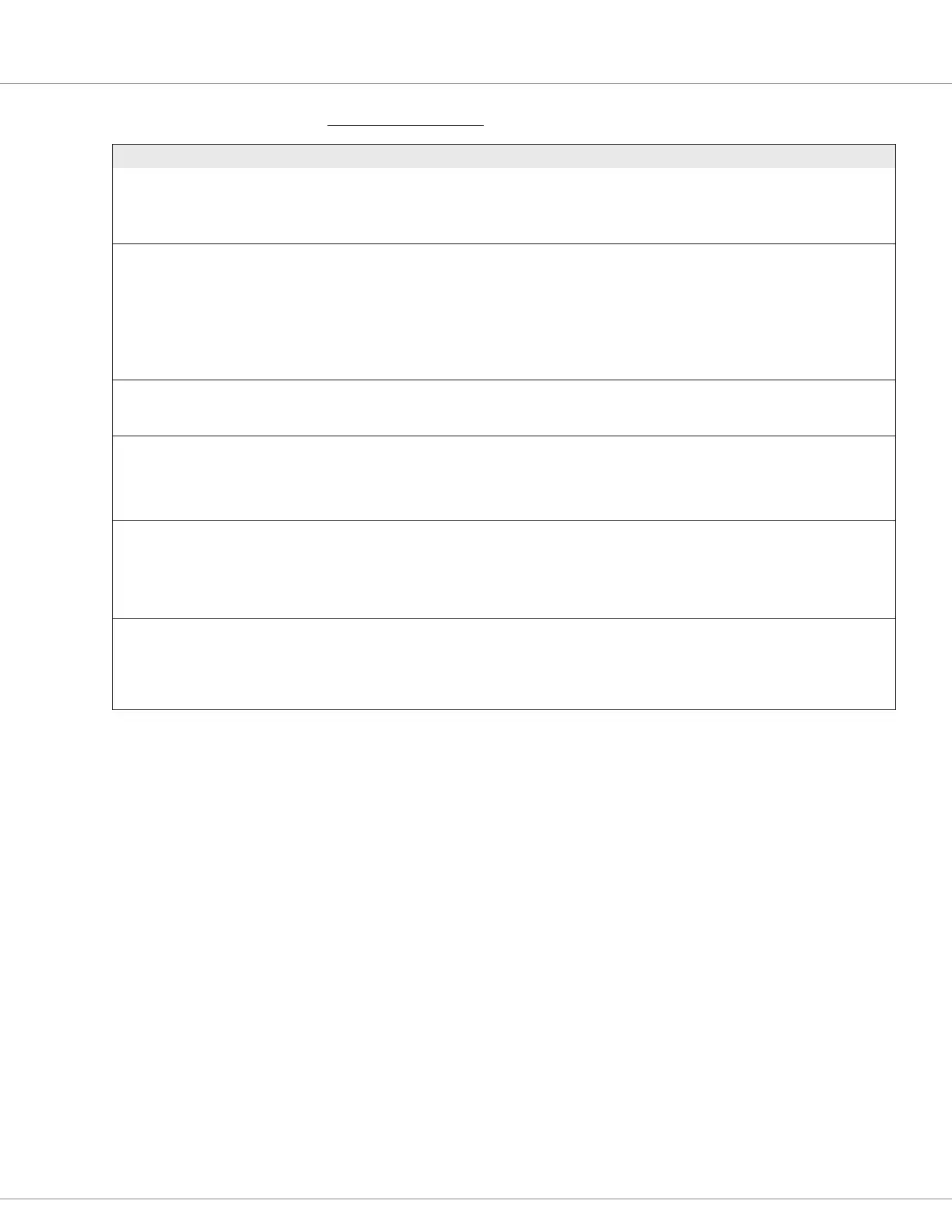

APPLICATION SETUP — CAN INTERFACE MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

CANopen Interlock

CANopen_Interlock_Enable

0x34B4 0x00

On/Off

On/Off

Off When programmed On, CAN NMT State must = 5 (operational

state) in order for the interlock to be set.

This parameter also occurs in the CAN Interface 2 menu.

Changing it in one menu also changes it in the other location.

Baud Rate

CAN_Baud_Rate

0x2001 0x01

–1 – 4

–1 – 4

0 Sets the CAN baud rate for the CANopen Ancillary system:

–1 = 100Kbps

0 = 125Kbps

1 = 250Kbps

2 = 500Kbps

3 = 800Kbps

4 = 1000Kbps.

Heartbeat Rate

CANopen_Heart_Beat_Rate

0x1017 0x00

16 – 2000 ms

0 – 2000

100 ms Sets the transmission rate of the CAN heartbeat messages from

the CANopen Ancillary system.

Emergency Message Rate

CAN_Open_Emergency_Inhibit_

Time

0x1015 0x00

0 – 6554 ms

0 – 65535

16 ms Sets the minimum transmission rate of the CAN Emergency

Messages from the CANopen Ancillary system. This prevents

quickly changing fault states from generating so many

emergency messages that they ood the CANbus. The step size

is 10 ms.

CAN NMT State

CAN_NMT_State

0x32A4 0x00

0 – 127

0 – 127

Read Only Controller CAN NMT state:

0 = initialization

4 = stopped

5 = operational

127= pre-operationalThis Read Only variable also occurs in the CAN Interface 2 menu.

CAN Node ID

Can_Node_Id

0x2000 0x01

0001 – FFFFh

1 – 65535

0026h

(0x26)

(38d)

Displays the controller’s Node ID, in hexadecimal.

For example: 0x26 = 38d

Do not assign 0x00 as a device’s CAN Node ID. Such an ID will

never be detected by CIT or the 1313 HHP, and therefore be

inoperable.

CAN ports 1 and 2

If the controller is equipped with two external CAN ports (Ports 1 and 2), each may have a unique

baud rate, and CANopen node ID. Either may be used for the secure node connection to the Curtis

programming tools (see Appendix D). Note that only one port at a time may be used for Curtis tools

connection. Note also that there is a single CANopen NMT state for the controller, which will be

indicated via heartbeats unique to each port’s node ID, but which can be changed by sending NMT

commands to either port. In addition, CANopen Emergency messages will be transmitted to all CAN

ports. Each port has a unique CANopen PDO conguration, and may receive and transmit unique

data for each port.

Non-isolated CAN models

CAN1 has the internal 120Ω termination when pins 21 and 34 are connected. CAN2 does not have

the internal 120Ω termination. For applications requiring CAN2 termination, add it externally from

the controller. On these models, the CAN-circuit reference is from the controller’s I/O ground (pins

7 and 18).

CAN1

CAN1 L = pin 35

CAN1 H = pin 23

CAN1 120-Ohm termination: externally connect (short) pins 21 and 34.

Loading...

Loading...