4 — PROGRAMMABLE PARAMETERS

pg. 79

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

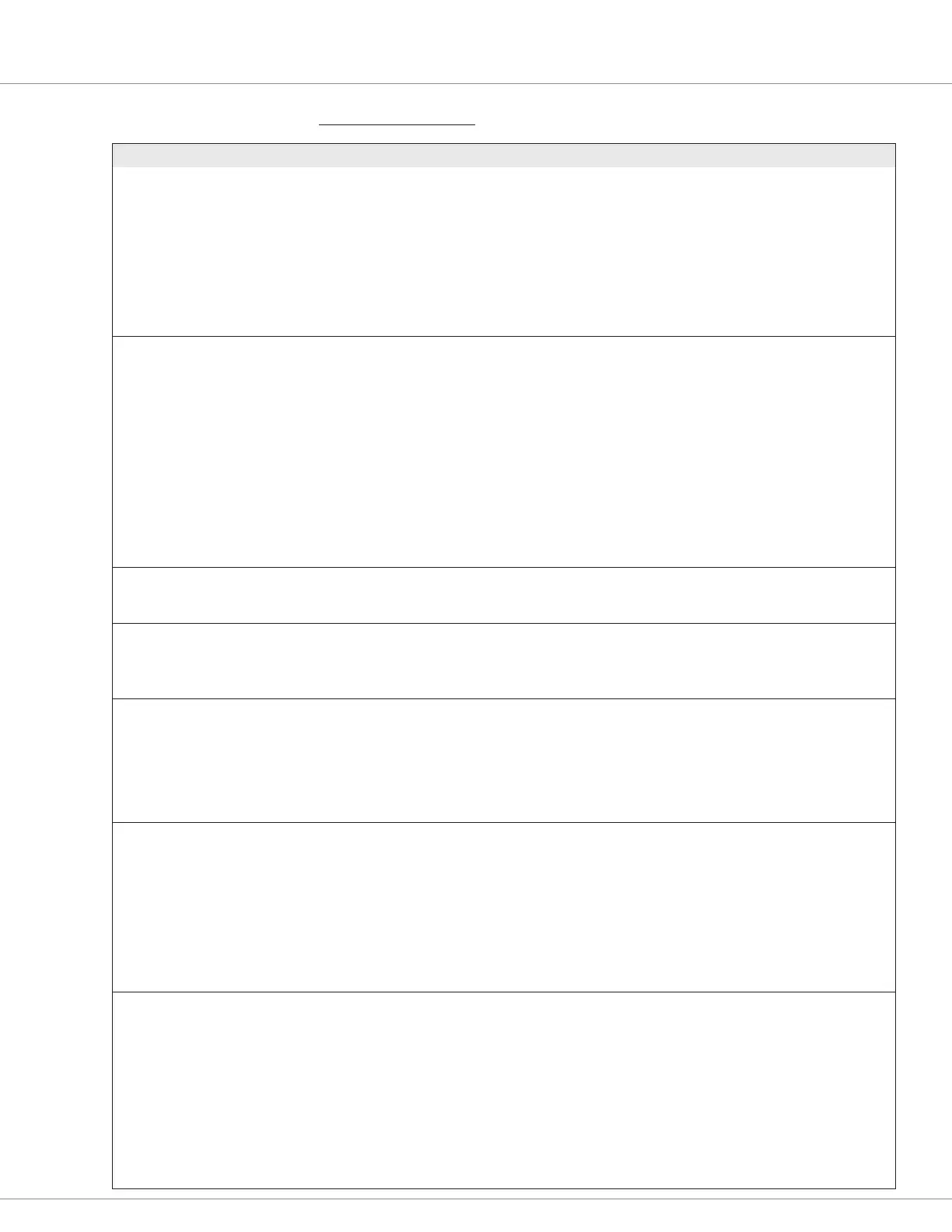

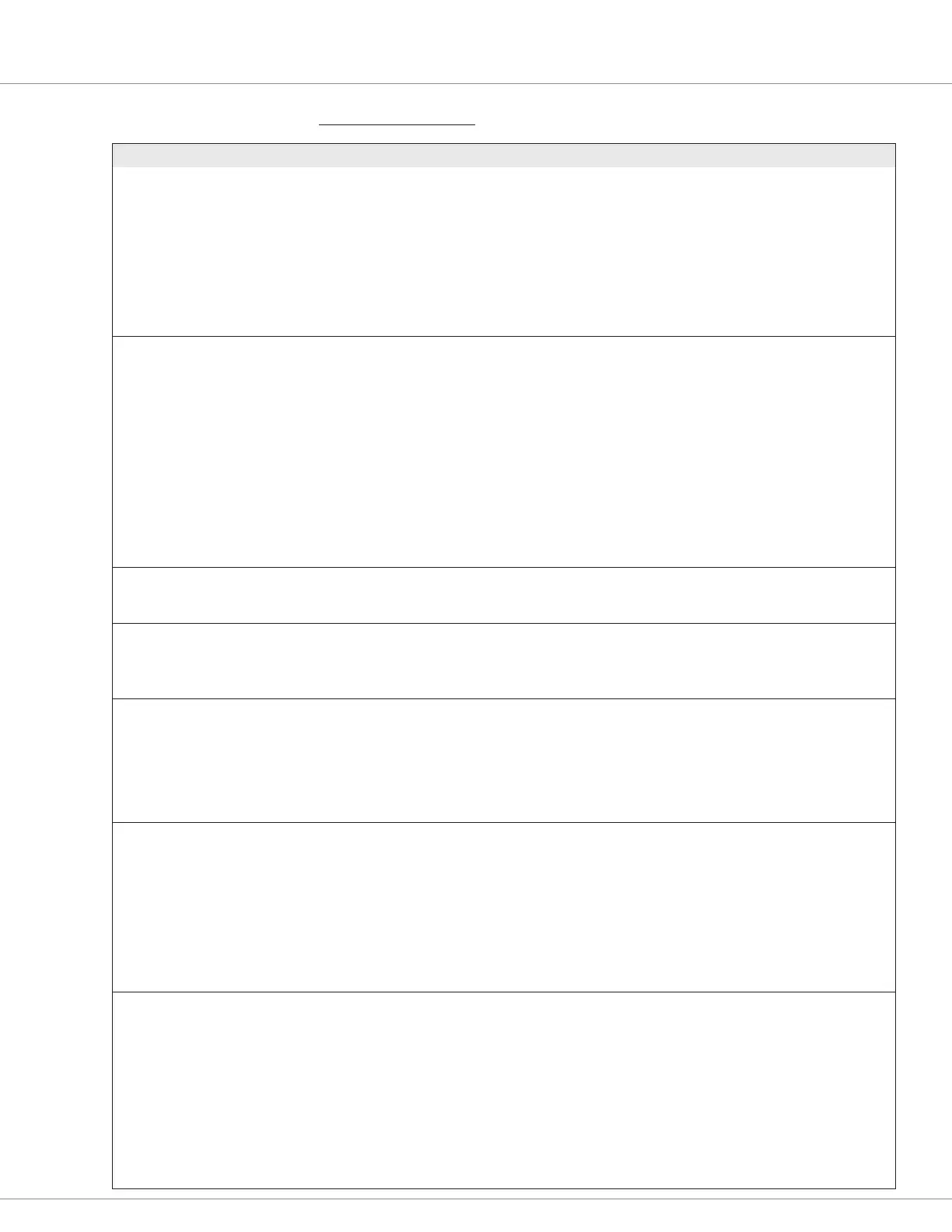

APPLICATION SETUP — MAIN CONTACTOR MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

Main Enable

Main_Enable

0x34C5 0x00

On/Off

On/Off

On When programmed On, the controller's native software

controls the main contactor when enabling the interlock. When

programmed Off, VCL controls the main contactor.

See the assignment parameter in Programmer/Controller Setup/

IO Assignments/Coil Drivers/Main Contactor Driver. The default is

Driver 3.

Note: With Main Enable programmed Off the controller will

not be able to open the main contactor in serious fault

conditions and the system will therefore not meet EEC

safety requirements.

Main State

Main_State

0x34C9 0x00

0 – 10

0 – 10

Read Only Main contactor state:

0 = open

1 = precharge

2 = weld check

3 = closing delay

4 = missing check

5 = closed (when Main Enable = On)

6 = delay

7 = arc check

8 = open delay

9 = fault

10 = closed (when Main Enable = Off)

Keyswitch Voltage

Keyswitch_Voltage

0x3398 0x00

0.00 – 105.00V

0 – 10500

Read Only Voltage at KSI (pin 1).

The value is in 0.01V steps.

Capacitor Voltage

Capacitor_Volts

CAN = 0x34C1 0x00

0.00 – 200.00V

0 – 20000

Read Only Voltage of the controller’s internal capacitor bank at the B+ terminal.

The value is in 0.01V steps.

Note that the precharge, main weld check and DNC tests affect this

reading when those actions are active.

Pull In Voltage

Main_Pull_In_Voltage

0x34C8 0x00

0 – 100 %

0 – 32767

0 % The main contactor pull-in-voltage parameter allows a high initial

voltage when the main contactor driver rst turns on to ensure

contactor closure. After 1 second, this peak voltage drops to the

contactor holding voltage. Typical is 100% to ensure closure.

Note: The Battery Voltage Compensated parameter (0x34C4)

controls whether the pull-in and holding voltages are battery

voltage compensated.

Holding Voltage

Main_Holding_Voltage

0x34C6 0x00

0 – 100 %

0 – 32767

0 % The main contactor holding-voltage parameter allows a reduced

average voltage to be applied to the contactor coil once it has

closed. Typical is 75-80% to conserve energy and coil heating.

Set this parameter (applied voltage) high enough to hold the

contactor closed during all vehicle shock and vibration conditions.

If the voltage is too low, the contactor tips may open when

subjected to shock and vibration conditions.

Note: The Battery Voltage Compensated parameter (0x34C4)

controls whether the pull-in and holding voltages are battery

voltage compensated.

Battery Voltage Compensated

Main_Driver_Battery_Voltage_

Compensated

0x34C4 0x00

On/Off

On/Off

On This parameter determines whether the main pull-in and holding

voltages are battery voltage compensated. When set On, the pull-

in and holding voltages are set relative to the set Nominal Voltage.

In other words the output voltage is adjusted to compensate for

swings in battery voltage so the percentage is relative to the set

Nominal Voltage not to the actual voltage.

For example suppose Nominal Voltage is set to 48V and Holding

Voltage is set to 75 % (36V) to the output driver. Now suppose the

bus voltage dips to 40V. If Battery Voltage Compensated = On, the

output will still be 36V (Nominal Voltage × Holding Voltage) to the

coil. If the Battery Voltage Compensated = Off, the output will be

30V (Actual Voltage × Holding Voltage) to the coil.

Loading...

Loading...