56

Starter System

KohlerEngines.com 22 690 01 Rev. --

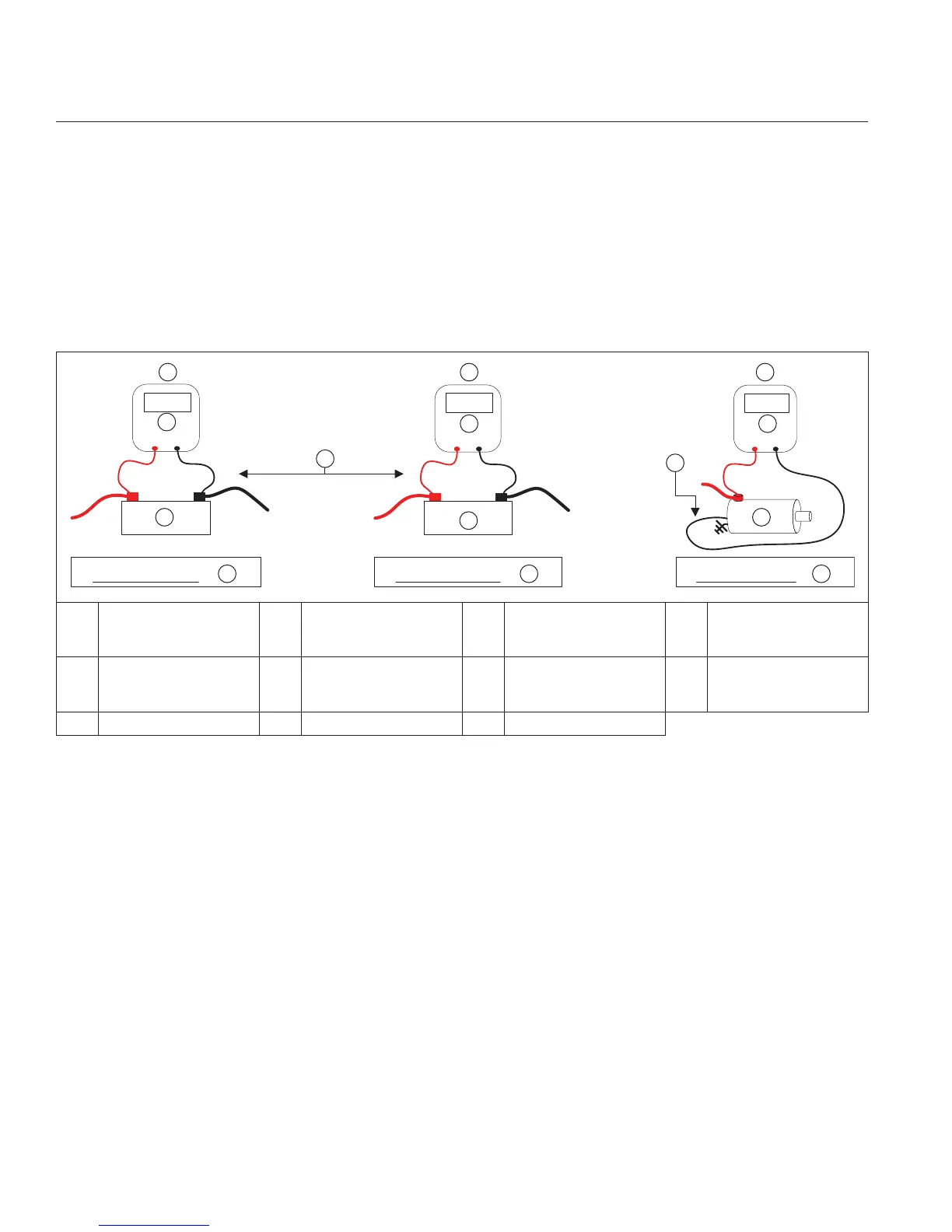

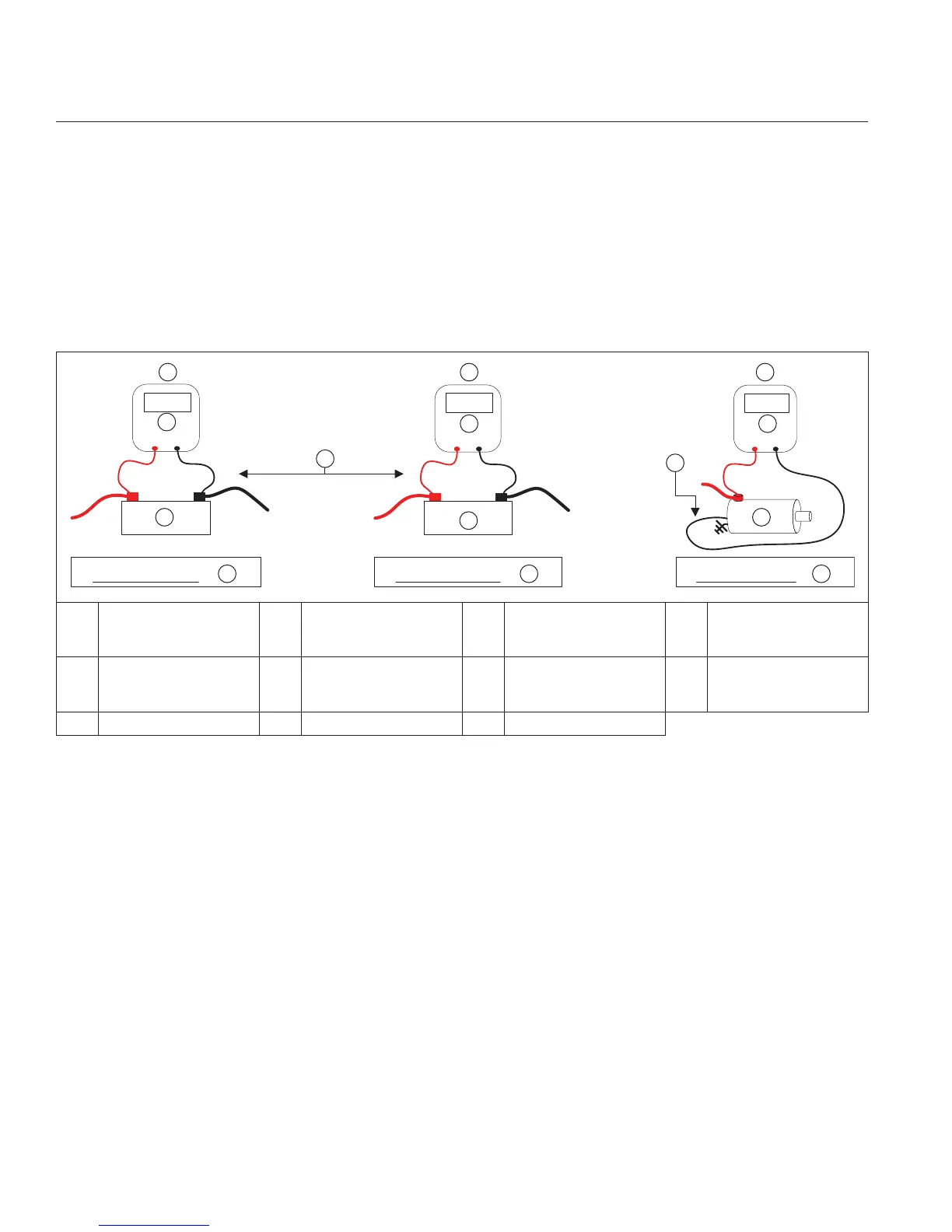

Inertia Drive Starter Tests

NOTE: Please perform following testing as near to conditions during failure.

Before Starting

● Disable ignition system: disconnect spark plug lead from spark plug, then ground spark plug lead to engine block

using mechanical means.

● Battery voltage should be tested and must be at 12.4 VDC or higher. Do not proceed if battery voltage is less than

12.4 VDC as battery should be charged.

● Test meter leads before use. (Set meter to Ohms and check for resistance reading of less than 0.5 Ohm.)

● If available, use clamping meter leads to assist with testing.

● Set meter to next highest voltage scale that includes 12 VDC.

● When taking readings, allow meter to stabilize before recording. Reading should stabilize after 3 to 5 seconds. If

reading continues to drop while cranking, stop test and perform a battery load test.

+-

+-

+-

+-

+

-

+-

D

E

A C B

F

D D

E

G

H

I J K

A

Test #1

Battery Voltage Test

(Static)

B

Test #2

Voltage Drop Across

Battery (Cranking)

C

Test #3

Voltage Drop Across

Starter (Cranking)

D DVOM

E Battery F Starter G

Touch meter leads

to actual battery

terminals.

H

Use starter end plate

as test point.

I Test #1 Results J Test #2 Results K Test #3 Results

Test 1 Conclusions

• If battery voltage is above 12.4 VDC continue to Test 2.

• If voltage is below 12.4 VDC, charge battery and retest.

• If battery will not hold a charge it should be replaced before continuing test or replacing starter.

Test 2 Conclusions

• If battery cranking voltage is above 9.0 VDC continue to Test 3.

• If battery cranking voltage is below 9.0 VDC you should check battery by using a load tester. Also check for external

engine load.

Test 3 Conclusions

• If diff erence between test 2 and test 3 is greater than 1 VDC check all positive and negative electrical connections

for corrosion and/or loose fasteners in starter circuit.

Loading...

Loading...