TP-6447 10/12 17Section 2 Installation

Making line or auxiliary connections. Hazardous voltage

can cause severe injury or death. To prevent electrical

shock deenergize the normal power source before making

any line or auxiliary connections.

Grounding electrical equipment. Hazardous voltage can

cause severe injury or death. Electrocution is possible

whenever electricity is present. Ensure you comply with all

applicable codes and standards. Electrically ground the

generator set and related equipment and electrical circuits.

Turn off the main circuit breakers of all power sources before

servicing the equipment. Never contact electrical leads or

appliances when standing in water or on wet ground because

these conditions increase the risk of electrocution.

NOTICE

Foreign material contamination. Cover the transfer switch

during installation to keep dirt, grit, metal drill chips, and other

debris out of the components. Cover the solenoid mechanism

during installation. After installation, use the manual

operating handle to cycle the contactor to verify that it

operates freely. Do not use a screwdriver to force the

contactor mechanism.

2.6.1 Source and Load Connections

Determine the cable size. Refer to the transfer switch

dimension drawing to determine the size and number of

conductors that can be used. Make sure that the cables

are suitable for use with the transfer switch lugs.

Watertight conduit hubs may be required for outdoor

use.

Drill the entry holes. Cover the internal components of

the ATS to protect them from metal chips and

construction grit. Then drill entry holes for the

conductors at the locations shown on the enclosure

drawings. Remove debris from the enclosure with a

vacuum cleaner.

Note: Do not use compressed air to clean the switch.

Cleaning with compressed air can cause debris to

lodge in the components and damage the switch.

Install and test the power conductors. Leave

sufficient slack in the conductors to reach all of the

power connecting lugs on the power switching device.

Test the power conductors after pulling them into

position and before they are connected to verify that they

are not defective and that they were not damaged during

installation.

Connect the cables. Be careful when stripping

insulation from the cables; avoid nicking or ringing the

conductor. Clean cables with a wire brush to remove

surface oxides before connecting them to the terminals.

Apply joint compound to the connections of any

aluminum conductors.

Refer to the wiring diagram provided with the switch.

The connection points on the contactor are labeled

Normal, Emergency, and Load. Be sure to follow the

phase markings (A, B, C, and N). For single-phase

systems, connect to A and C.

Note: Connect the source and load phases as

indicated by the markings and drawings to

prevent short circuits and to prevent phase-

sensitive load devices from malfunctioning or

operating in reverse.

Verify that all connections are consistent with drawings

before tightening the lugs. Tighten all lug connections to

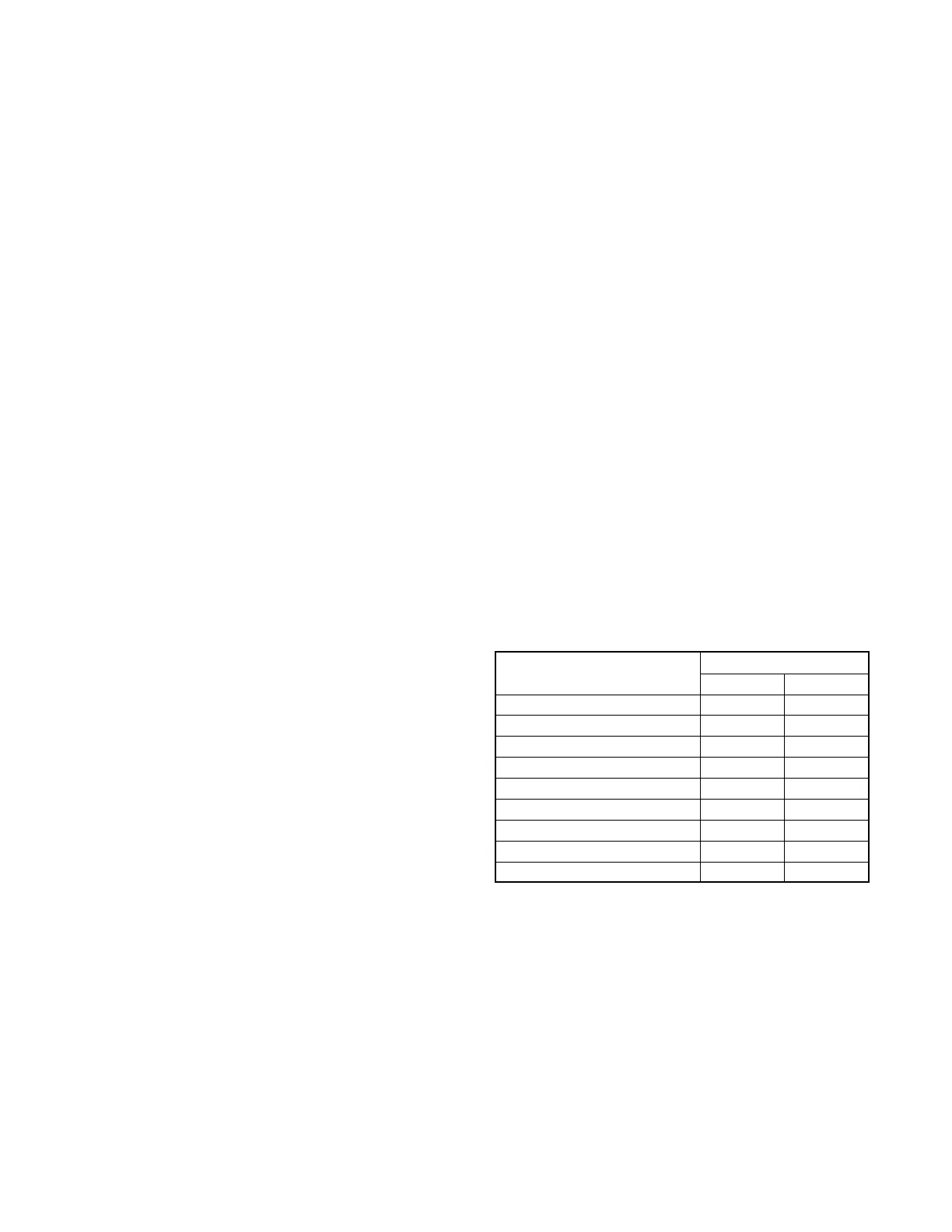

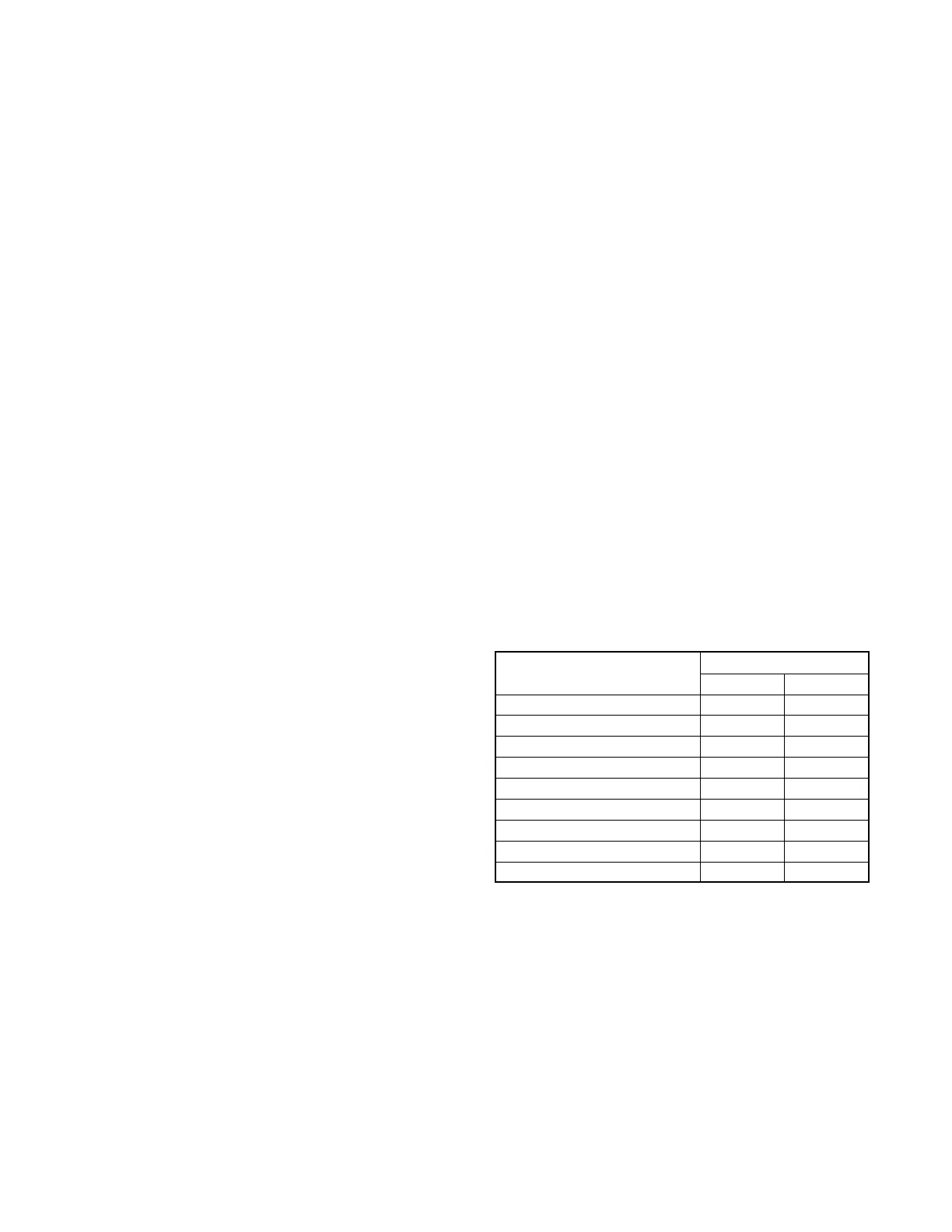

the torque values shown in Figure 2-10. Carefully wipe

off any excess joint compound after tightening the

terminal lugs.

Socket Size Across Flats, in.

Bolt Torque

Nm Ft. lb.

1/8 5 4

5/32 11 8

3/16 14 10

7/32 16 12

1/4 23 17

5/16 31 23

3/8 42 31

1/2 57 42

9/16 68 50

Figure 2-10 Tightening Torque for Lugs

Loading...

Loading...