18

Troubleshooting

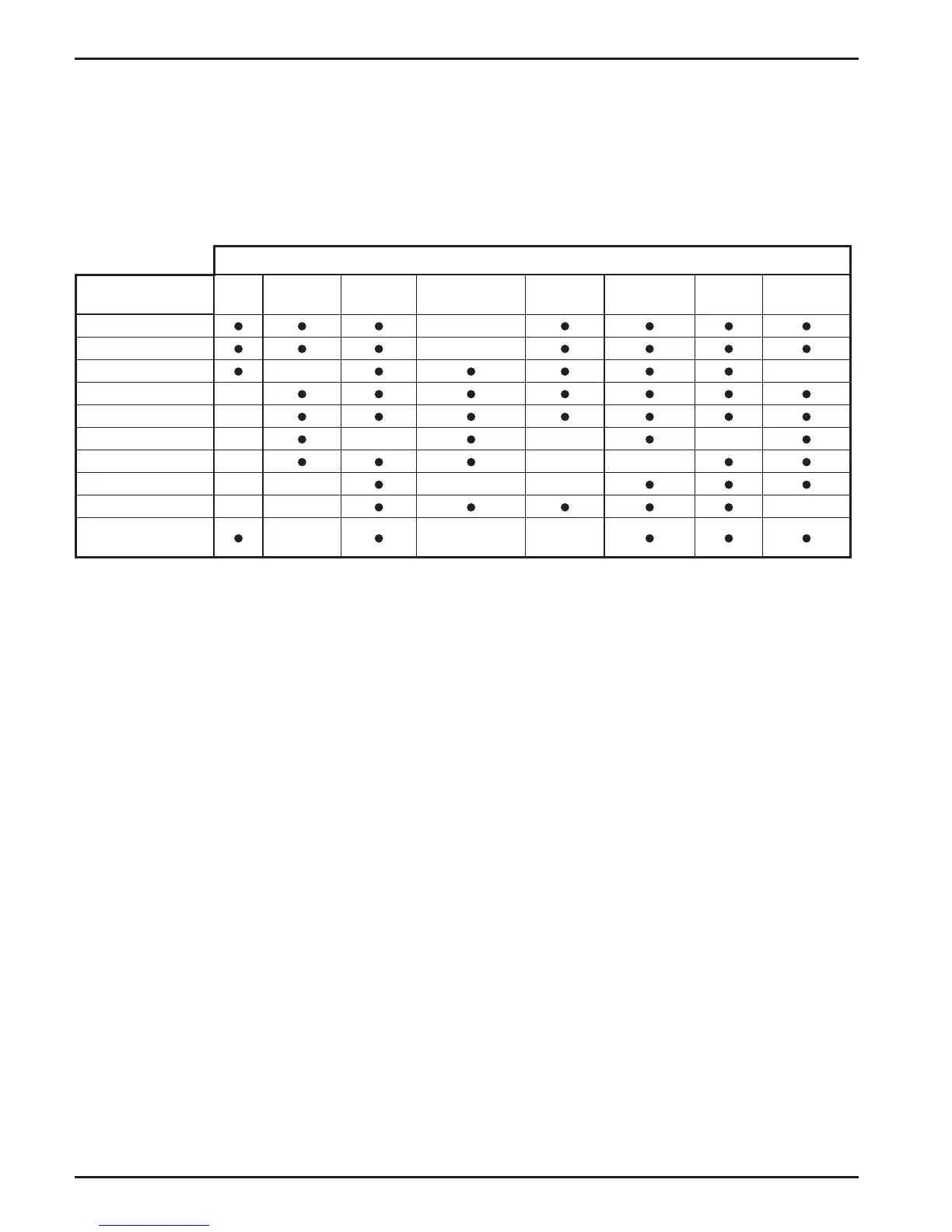

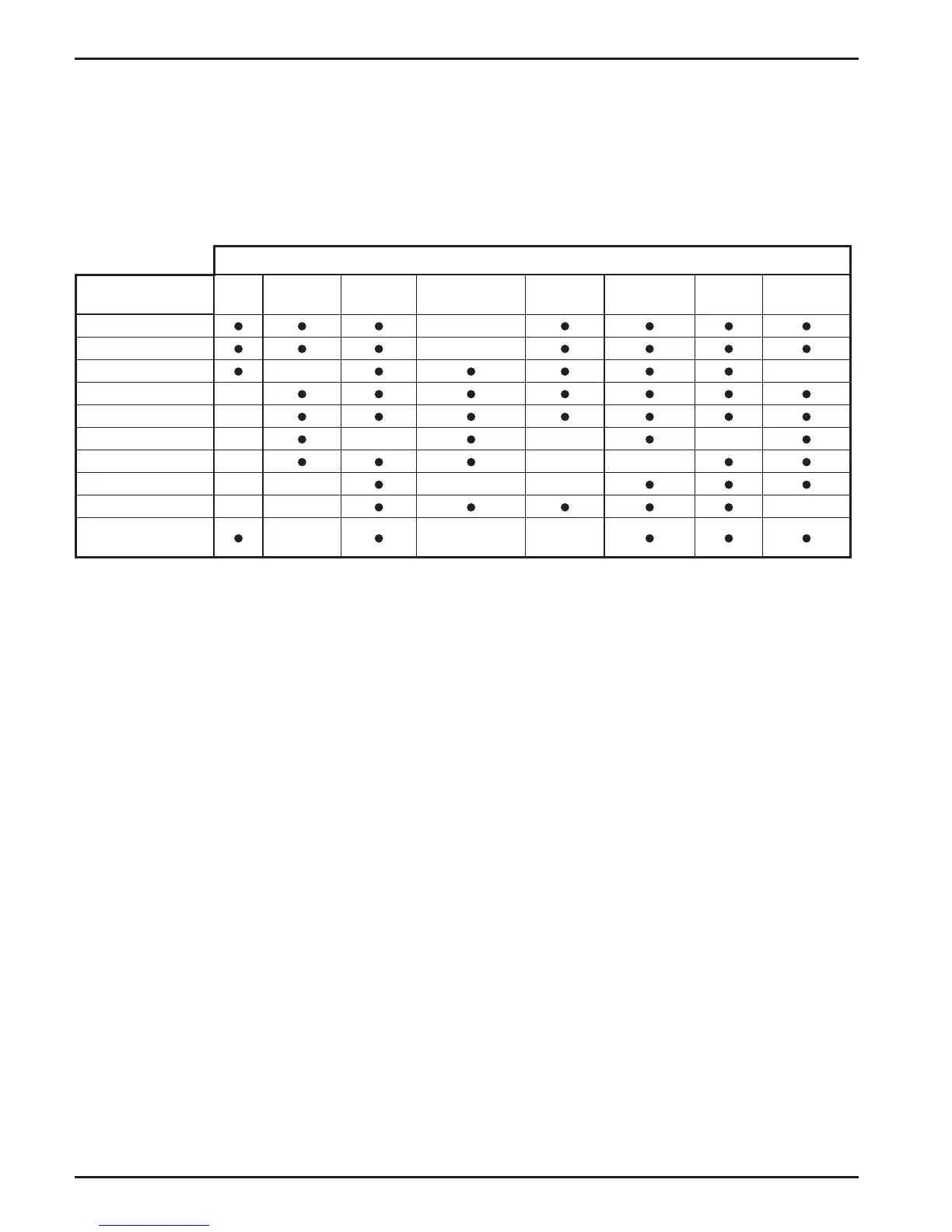

Whentroublesoccur,besuretocheckthesimplecauseswhich,atrst,mayseemtooobvioustobeconsidered.

Forexample,astartingproblemcouldbecausedbyanemptyfueltank.Somecommoncausesofenginetroubles

are listed in the table below.

Donotaempttoserviceorreplacemajorenginecomponents,oranyitemsthatrequirespecialtimingor

adjustmentprocedures.HavethisworkdonebyaKohlerEngineServiceCenter.

Storage

Iftheenginewillbeoutofservicefortwomonthsor

more, use the following storage procedure:

1. Cleantheexteriorsurfacesoftheengine.

2. Changetheoilwhiletheengineisstillwarmfrom

operation. Refer to Change Oil.

3. Thefuelsystemmustbecompletelyemptied,

or the gasoline must be treated with a stabilizer

topreventdeterioration.Ifyouchooseto

use a stabilizer, follow the manufacturers

recommendations, and add the correct amount

for the capacity of the fuel system. Fill the fuel

tank with clean, fresh gasoline. Run the engine

for5minutestogetstabilizedfuelintothe

carburetor.

To empty the system, run the engine until the

tank and system are empty.

4. Removethesparkplug.Addonetablespoonof

engineoilintothesparkplughole.Installthe

plug,butdonotconnectthepluglead.Crankthe

engine two or three revolutions.

5. Removethesparkplug.Coverthesparkplug

hole with your thumb, and turn the engine over

untilthepistonisatthetopofitsstroke.(Pressure

againstthethumbisgreatest.)Reinstalltheplug,

but do not connect the plug lead.

6. Storetheengineinaclean,dryplace.

Transport

1. Turn the fuel valve to the OFF position.

2. Tightenthefuelcap.

3. Readandfollowthetransportguidelines

provided by equipment manufacturer.

Possible Cause

Problem

No

Fuel

Improper

Fuel

Dirt In

Fuel Line

Dirty

Debris Screen

Incorrect

Oil Level

Engine

Overloaded

Dirty Air

Cleaner

Faulty

Spark Plug

Will Not Start

Hard Starting

Stops Suddenly

Lacks Power

Operates Erratically

Knocks or Pings

Skips or Misres

Backres

Overheats

High Fuel

Consumption

Loading...

Loading...