10

Oil Traps

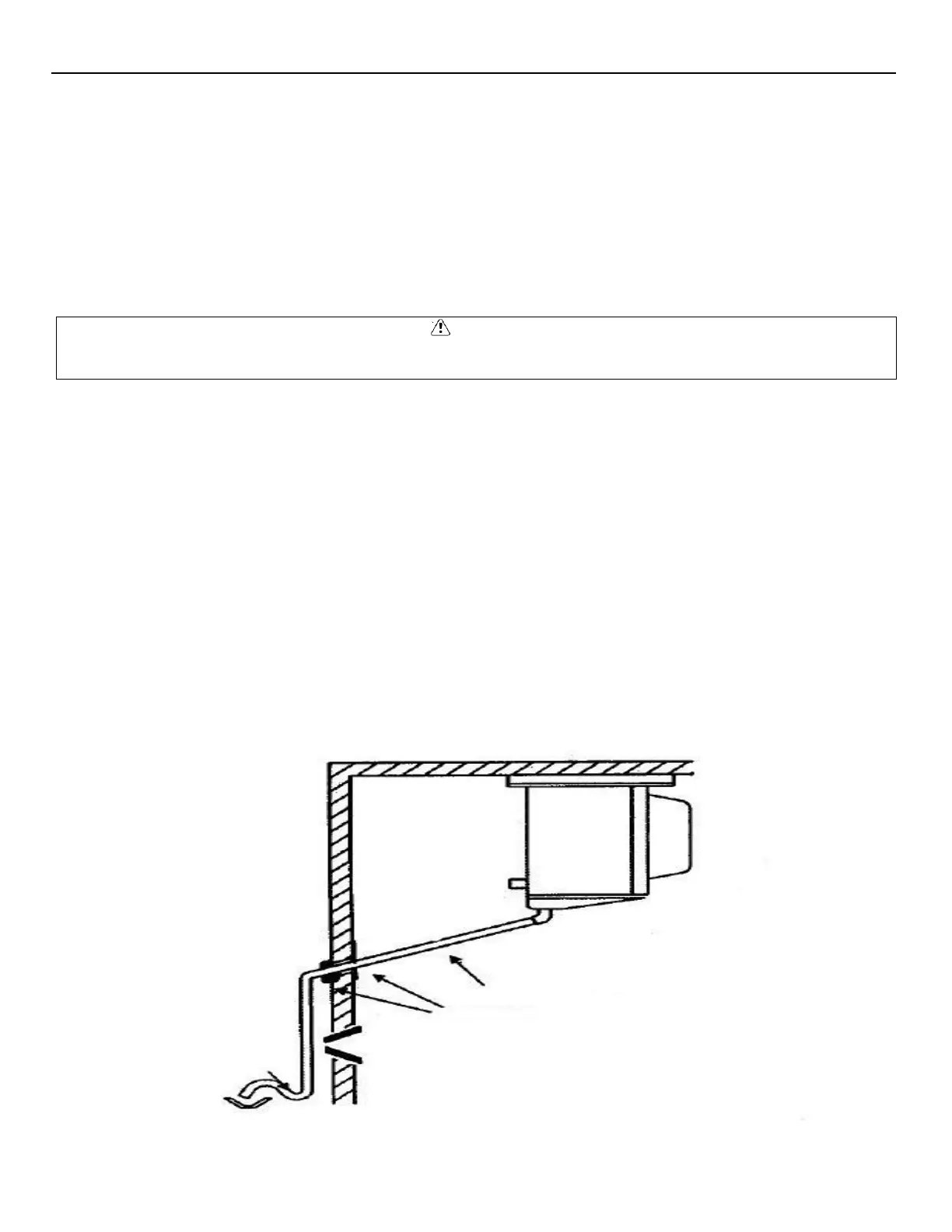

• To ensure proper oil return to the compressor, a P-type oil trap should be installed at the base of each suction riser of

four feet or more.

• The suction trap must be the same size as the suction line.

• Additional traps are necessary for long vertical risers. Add a trap for each length of pipe (approximately 20 feet) to

insure proper oil return.

• Suction lines must slope ¼” per 10 feet toward the compressor.

• Install a suction line trap at the evaporator outlet if the suction line rises to a point higher than the connection on the

evaporator.

Failure to properly install oil traps can prevent sufficient oil return to the compressor resulting in premature compressor

Drain Lines

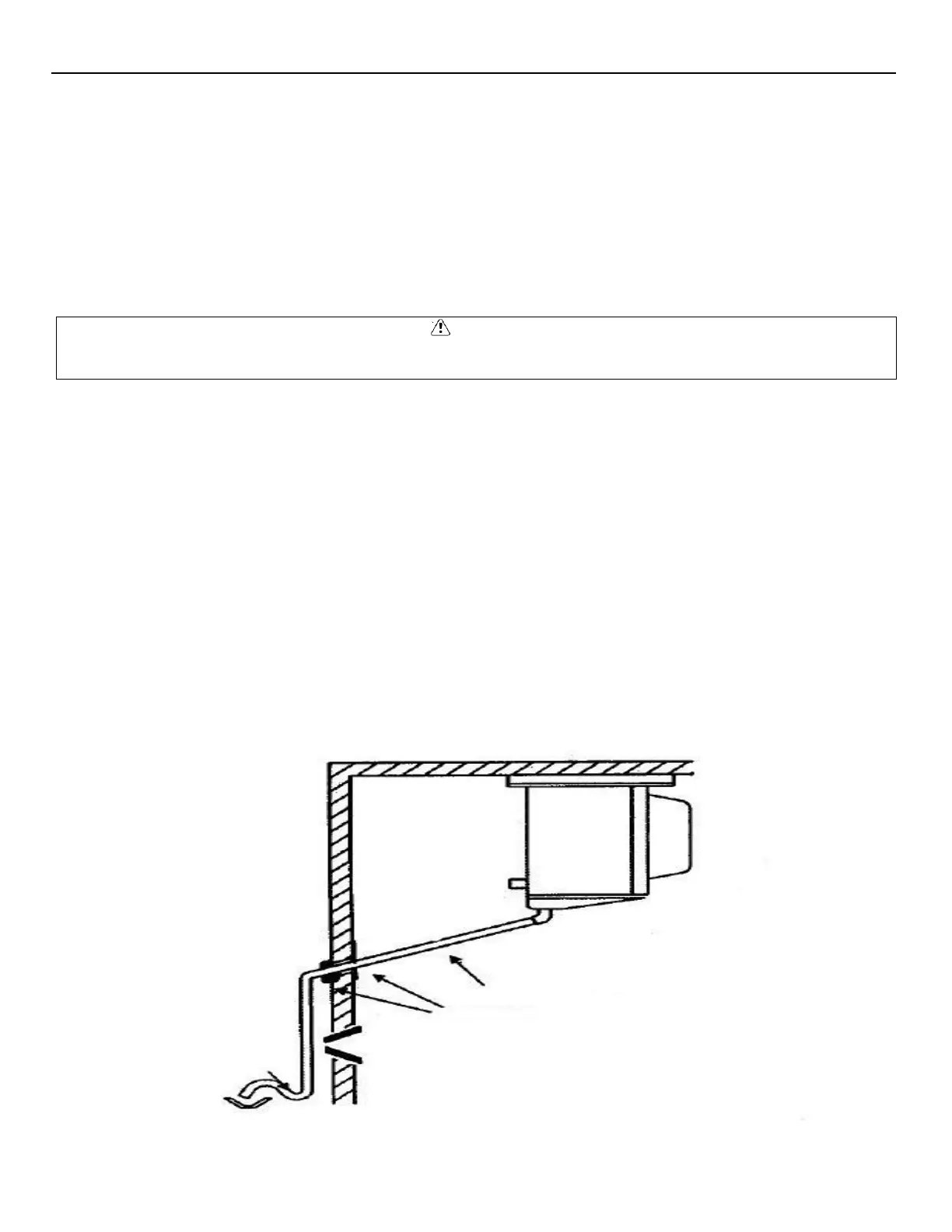

• Evaporator coil drain lines should be pitched a minimum of 1/2” per foot to allow proper drainage and exit the walk-in

as quickly as possible.

• Insulate and seal the drain line where it passes through the wall.

• Copper drain line is required.

• Freezer compartment drain lines must have heat tape wrapped around the copper drain line and must have ¾” thick

insulation tubing.

• Do not locate drain line P-traps within the freezer space.

• Do not reduce the drain line size.

• Locate a drain line P-trap outside of the cooler space.

• Any outdoor P-traps exposed to low ambient temperatures should be wrapped with a drain line heater (provide 20

watts of heat per foot of drain line at 0°F, 30 watts per foot at -20°F.

• Freezer/cooler combo boxes can have one common drain line. However, there must be a P-trap located between the

freezer evaporator and the cooler evaporator located inside the cooler compartment.

• The cooler compartment P-trap should be located between the cooler evaporator and the external drain location.

Loading...

Loading...