25

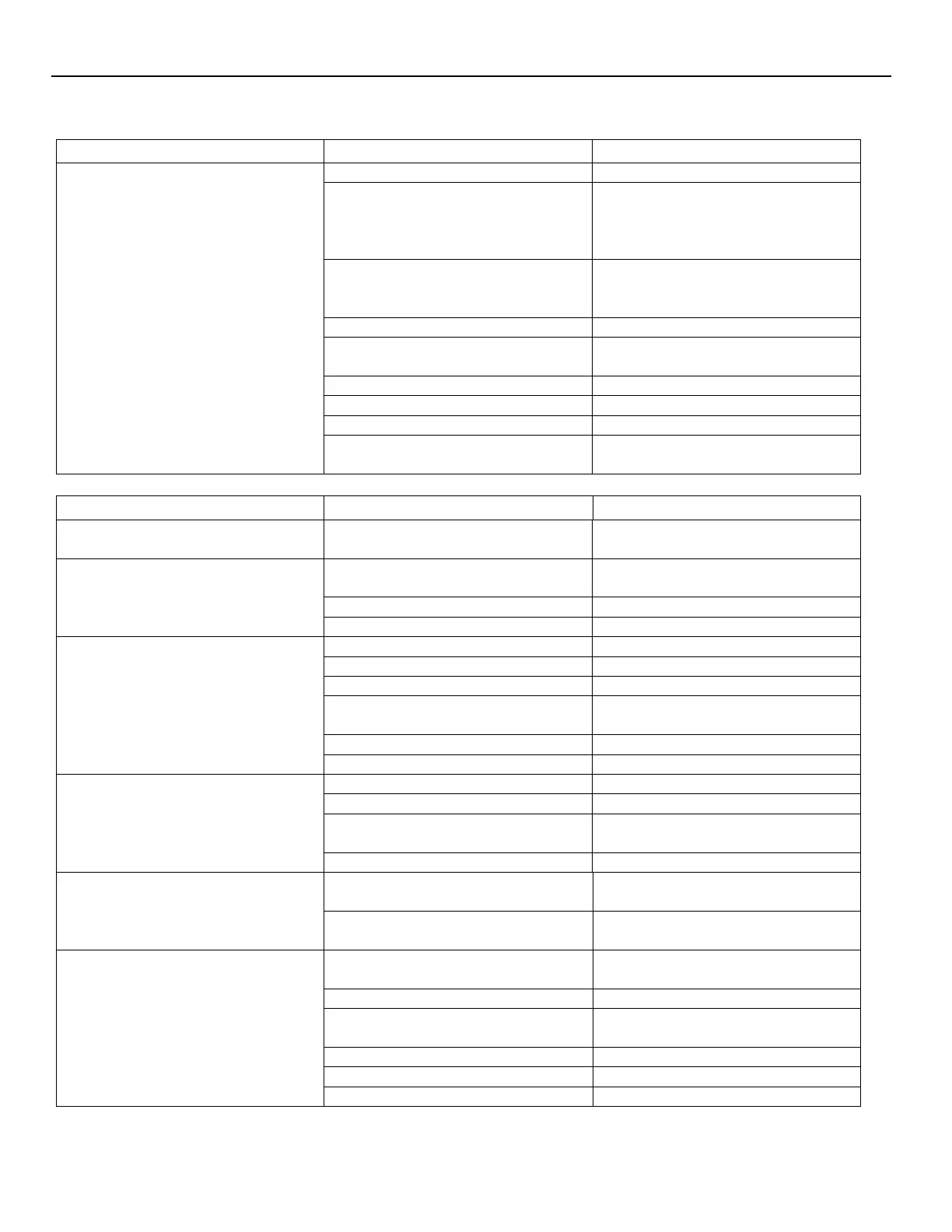

Condensing Unit Troubleshooting

Check electrical circuits and motor

winding for shorts or grounds.

Investigate for possible overloading.

Replace fuse after fault is corrected.

Thermal overloads tripped

Overloads are automatically reset.

Check unit closely when unit comes

Defective contactor or coil

System shut down by safety devices

Determine type and cause of shutdown

and correct

None. Wait until cooling is required.

Liquid line solenoid will not open.

Low pressure switch will not close.

Check motor for open windings or short

circuit.

Check all wire junctions. Tighten all

terminal screws.

Compressor noisy or vibrating

Flooding of refrigerant into crankcase

Check superheat setting of expansion

valve

Non-condensable in system

Recover, evacuate and charge

System overcharged with refrigerant

Discharge shut-off valve partially closed

Check electrical circuit or replace

defective fan motor

Insufficient condenser air supply

Check for cause and correct

Faulty head pressure control

Check head pressure control operation.

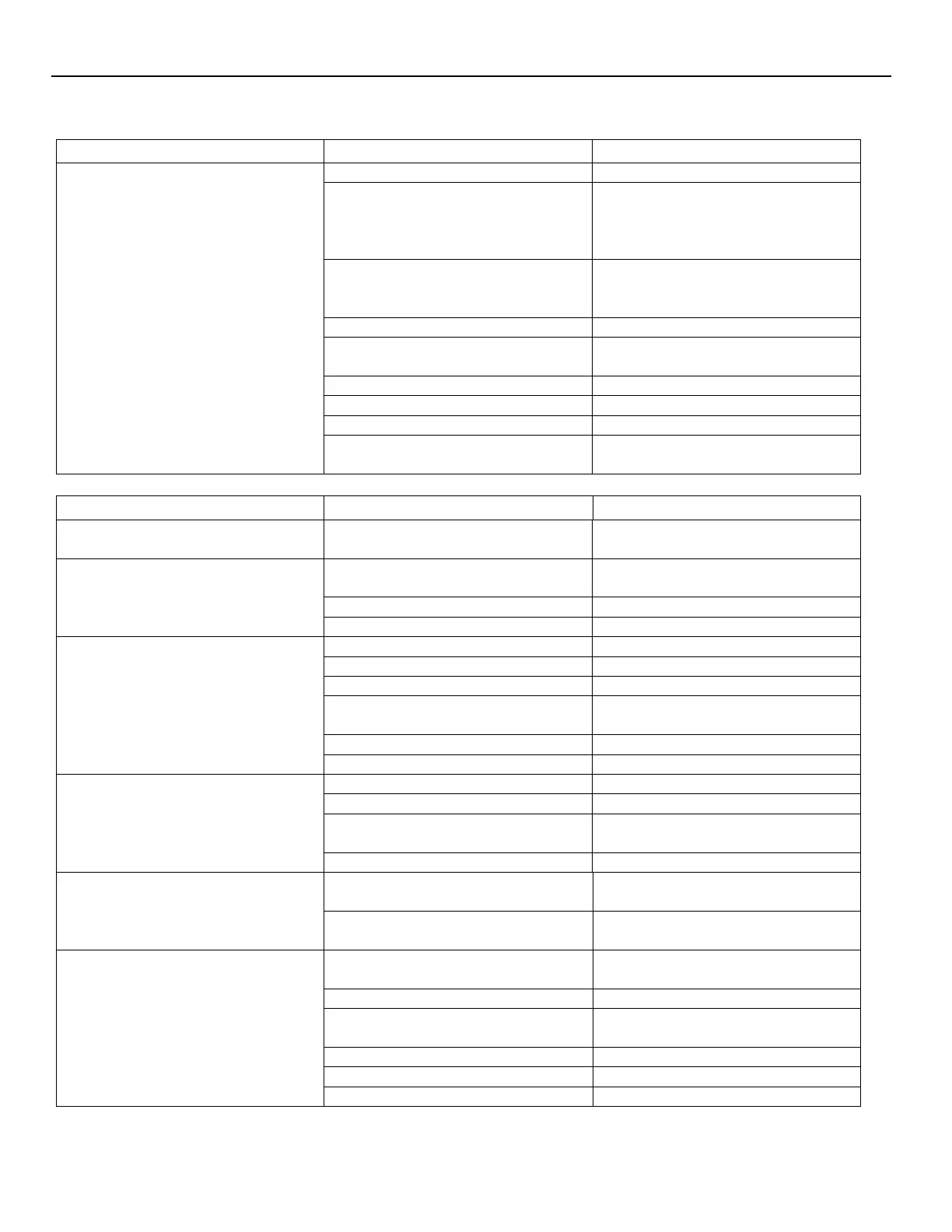

Suction shut-off valve partially closed

Insufficient refrigerant in system

Locate and repair leak, recover,

evacuate and recharge

Check for proper refrigerant charge

Reduce load or add additional

equipment

Expansion valve overfeeding

Secure and insulate TXV bulb or if

required adjust superheat.

Locate and repair leak, recover,

evacuate and charge.

Clogged liquid line or suction line filter-

drier

Expansion valve malfunctioning

Check and reset for proper superheat

Condensing temperature too low

Check head pressure control

Loading...

Loading...