2

GB

Contents

Safety ..................................................2

First start-up Instructions ..................... 2

Starting and Stopping .......................... 3

Adjustment for max. Capacity..............3

Piping Instructions ...............................4

Selection of Intake Nozzle ................... 5

Clearing a blocked Pipe System..........5

Bin clean-out........................................5

Maintenance ........................................ 6

Trouble shooting .................................. 7

Conveying Capacity.............................8

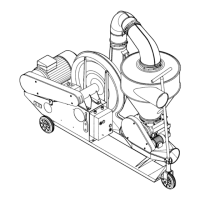

Principle of Operation ........................ 10

Function and use of Air Regulator ..... 11

Technical Data ................................... 12

Safety

1. Take care that all the guards

areincorrectpositionandxed

during operation.

2. Always stop the machine prior to

greasing, adjusting or repair.

3. Blower noise can be irritating.

Ear protection should be used

under long-term continuous

exposure.

4. Use eye protection when work-

ing in the vicinity of the intake

nozzle.Kernelscanyoutofthe

secondary air opening, causing

eye damage if proper protection

is not worn.

5. Avoid open suction pipes.

Clothing or objects can be

drawn into the machine and

cause injury to a person or

damage to the machine.

6. After conveying treated grain the

machine and the pipe system

should be carefully cleaned out.

7. Always use a discharge cyclone

to decelerate the grain and to

separate it from the air stream.

First Start-up

Instructions

1. All wiring must be made by a

certiedelectrician.

Min. fuse at 3 x 380 V

(recommended):

SUC 100E: 25 Amp.

SUC 150E: 35 Amp.

SUC 200E: 35 Amp.

SUC 300E: 63 Amp.

SUC 500E: 100 Amp.

2. Make sure that the direction of

rotation of blower and rotary

valve is correct (see arrows on

blower and rotary valve).

3. Check that the belt tension is

correct.

4. Make sure that all bolts are

tightened. Retighten the bolts

aftertherstdayofoperation.

Loading...

Loading...