GB-8

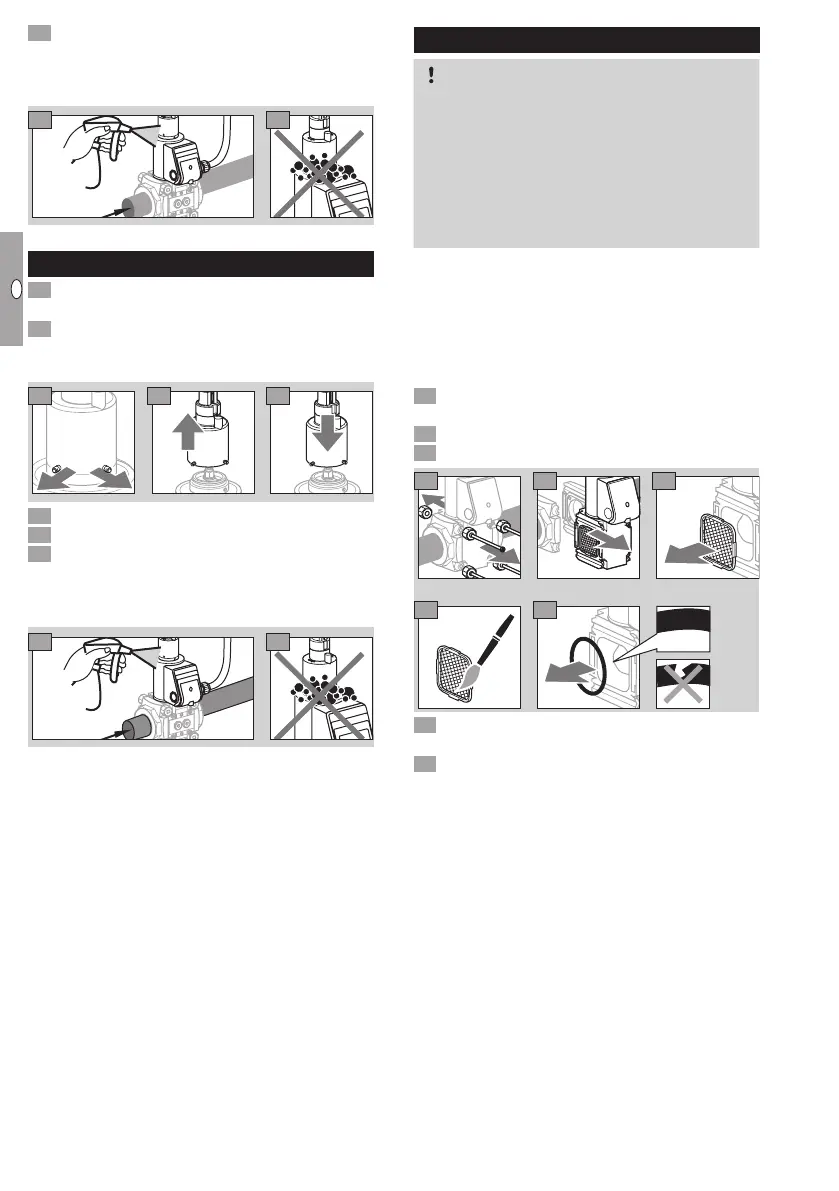

16 Set the start gas rate, see page 6 (Setting

the start gas rate on VAS../L, VCS..L). The con-

nection between solenoid actuator and damping

unit must then be checked for tightness.

N

2

<

–

1,5 x p

u max

18

17

Gewindestifte

M3 fest

einschrauben.

Replacing the damping unit

1 Disconnect the system from the electrical power

supply.

Shut off the gas supply.

▷

Loosen the M3 setscrews (1.5 mm hexagon

socket), but do not unscrew completely.

M3

4

5

3

6 Screw the M3 setscrews back in again.

7 Open the solenoid valve and the gas supply.

8 Set the start gas rate, see page 6 (Setting

the start gas rate on VAS../L, VCS..L). The con-

nection between solenoid actuator and damping

unit must then be checked for tightness.

N

2

<

–

1,5 x p

u max

10

9

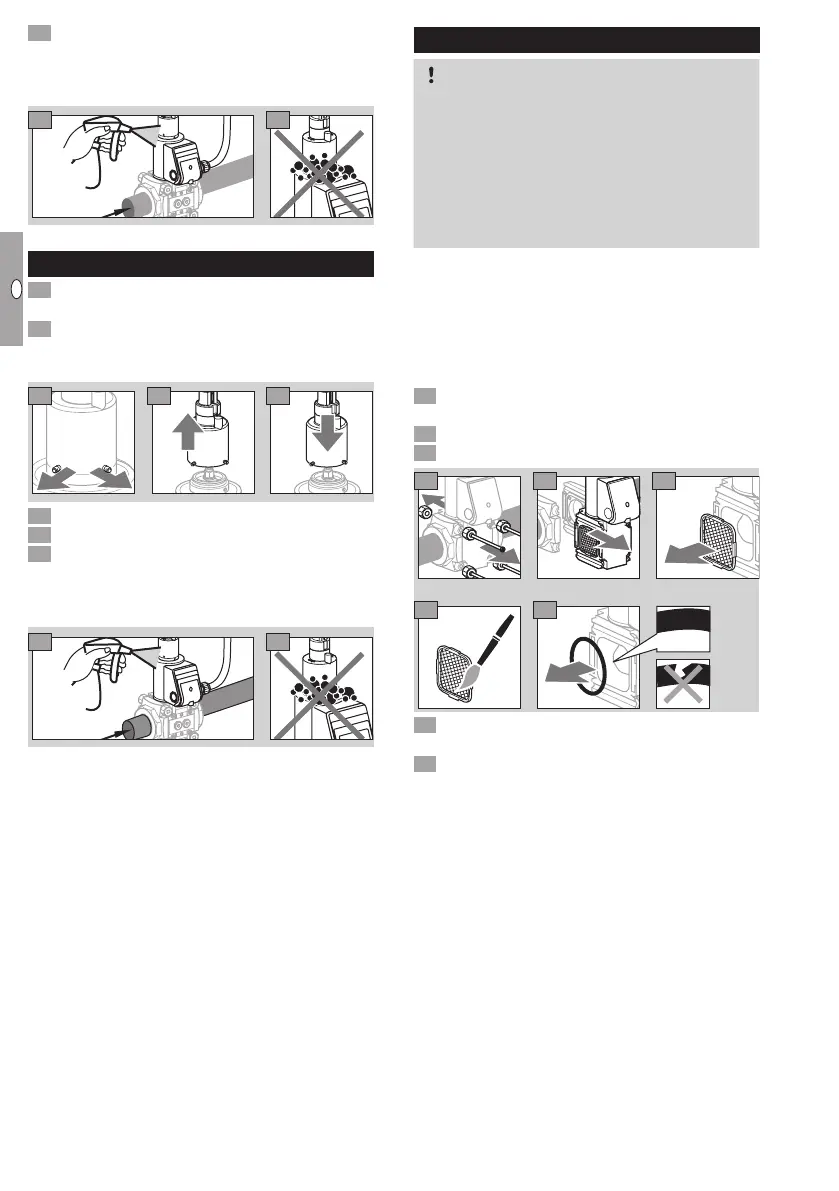

Maintenance

CAUTION

In order to ensure smooth operation, check the

tightness and function of the VAS:

– Once per year, twice per year in the case of

biogas; check for internal and external tightness,

see page6 (Tightness test).

– Check electrical installations once a year in line

with local regulations; pay particular attention

to the PEwire, see page4 (Wiring).

▷ If the flow rate has dropped, clean the strainer.

▷

If more than one valVario control is installed in

series: the controls may only be removed from

the pipeline and reinstalled on the inlet and outlet

flange all at once.

▷ We recommend replacing the seals, see acces-

sories, seal set for sizes 1 – 3.

1 Disconnect the system from the electrical power

supply.

Shut off the gas supply.

Undo connection parts.

4 5

87

6

9 Once the seals have been replaced, follow the

reverse procedure to reassemble the unit.

10 Then check the unit for internal and external

tightness, see page6 (Tightness test).

Loading...

Loading...