IFD244, IFD258 · Edition 06.23

EN-2

2 CHECKING THE USAGE

IFD244/IFD258

For atmospheric burners or forced draught burners

used in multiple burner applications, where a central

control system is used for pre-purge and for mon-

itoring the limits. For direct ignition and monitoring

of gas burners in continuous operation. Suitable for

intermittent operation thanks to its fast reaction to

different process requirements. 2-digit 7-segment

display for indicating program status and flame

signal intensity.

IFD..I

With integrated ignition.

WARNING

– The user must ensure that the high-voltage

output (IFD..I) is protected against accidental

contact.

– The IFD..I may not be used for domestic,

commercial and trade, or small firm application

due to emitted electromagnetic interference.

IFD244

Gas burner monitoring with a flame rod. For ground-

ed mains. With restart after a flame failure.

IFD258

Gas burner monitoring with a flame rod or a UV

sensor.

In the case of UV control with UV sensors of Type

UVS, the IFD may be used for intermittent operation

only. This means that operation must be interrupted

once within 24hours.

Ionization control is possible in both grounded and

ungrounded systems.

Ignition and monitoring with a single electrode is

possible (single-electrode operation).

The cut-off point can be set using a potentiometer.

The behaviour in the event of flame failure during

operation can be selected using a switch. Either

an immediate fault lock-out or an automatic restart

occurs.

➔ Mains voltage, ambient temperature, safety

time, enclosure, and with IFD..I also the ignition

voltage (peak-peak) and ignition current– see

type label.

IFD

CE-0063BXXXXX

230 VAC

50/60 Hz

-20/+60 °C

-4/+140 °F

ts 5/1s

IP 54/NEMA 3

➔ No condensation permitted on the PC boards

(enclosure IP54).

➔ Length of sensor cable:

ionization control: max. 75m,

UV control: max. 100m.

➔ In the event of an automatic restart, the program

sequence started must match the application

and the burner must be able to restart as intend-

ed in all operating phases.

2.1 Type code

IFD Automatic burner control unit for contin-

uous operation

2 Series 200

4 Ionization control

5 Ionization or UV control

4 Restart in the event of flame failure

8 Immediate fault lock-out or restart,

switchable

-3 Safety time on start-up: 3s

-5 Safety time on start-up: 5s

-10 Safety time on start-up: 10s

/1 Safety time during operation: 1s

W Mains voltage: 230V AC, 50/60Hz

Q Mains voltage: 120V AC, 50/60Hz

Y Mains voltage: 200V AC, 50/60Hz

P Mains voltage: 100V AC, 50/60Hz

I Integrated electronic ignition

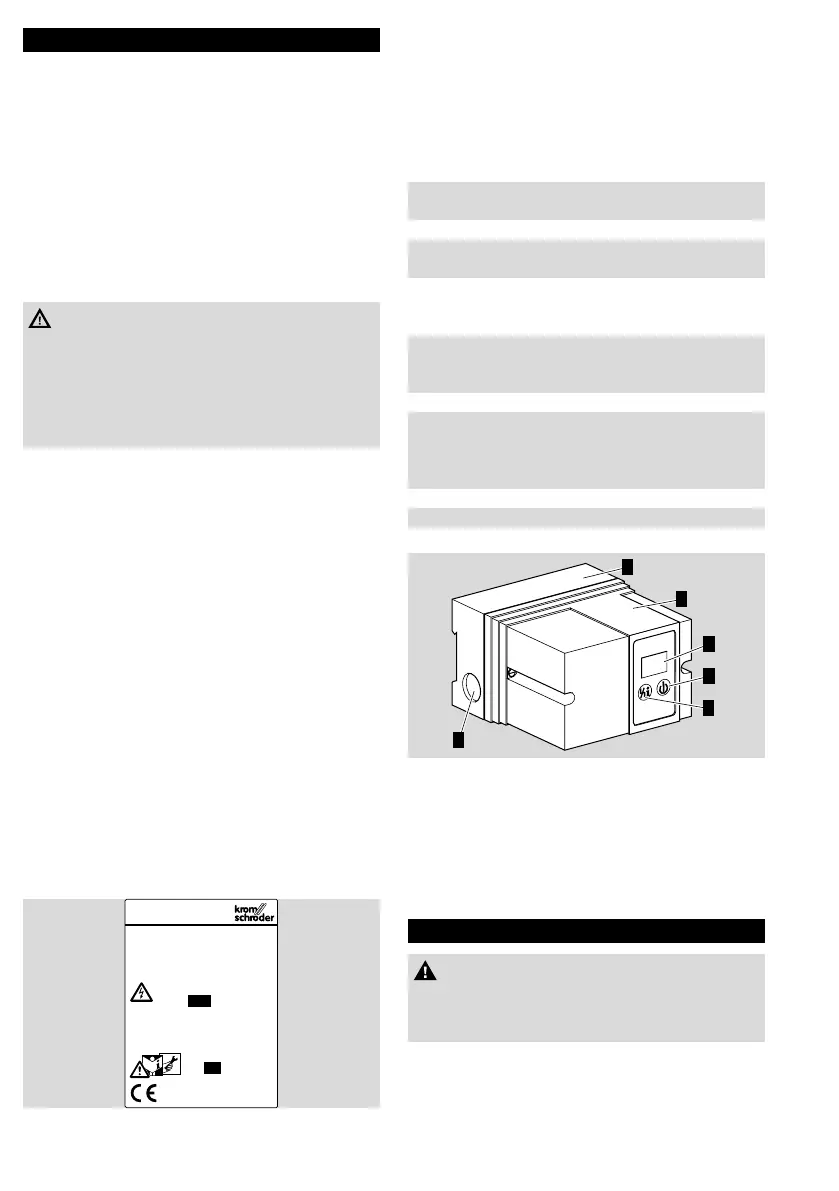

2.2 Part designations

2

6

3

1

4

5

1 LED display for program status and fault mes-

sages

2 On/Off button

3 Reset/Information button

4 Lower housing section

5 Upper housing section

6 Knock-out hole for M16 cable gland

3 INSTALLATION

CAUTION

– Dropping the device can cause permanent

damage. In this event, replace the entire device

and associated modules before use.

➔ Installation position as required.

➔ Eight knock-out holes are pre-prepared for

wiring, M16 plastic cable gland for 8 to 10mm

cable diameter.

Loading...

Loading...