5 Installation/Dismantling

23 of 44

4STQ

2580.821/04-EN

5.3.5 Installing the double cartridge seal C120/120M1-4STQ

CAUTION

Use of grease or other permanent lubricants

Torque transmission impeded/ overheating of and damage to the pump!

▷ Never use grease or other permanent lubricants for fitting the torque-

transmitting elements of a mechanical seal.

▷ Use soft soap to reduce any friction caused during assembly.

▷ Never coat the mechanical seal faces with grease or oil.

ü The relevant documentation for installing the mechanical seal is observed.

(ðSection9.1.6,Page39)

ü The back pull-out unit has been removed from the pump casing and safely

positioned and secured in a horizontal position.

ü The original 4STQ cartridge seal is fully assembled and undamaged.

1. Apply a suitable lubricant to the O-rings. Ensure that no permanent lubricant

comes into contact with the O-rings, in order to guarantee reliable torque

transmission.

2. Insert O-rings412.54 and 412.55 in discharge cover163. Ensure that no

permanent lubricant is used.

3. Fit O-ring412.59 on the shoulder of shaft seal housing441.

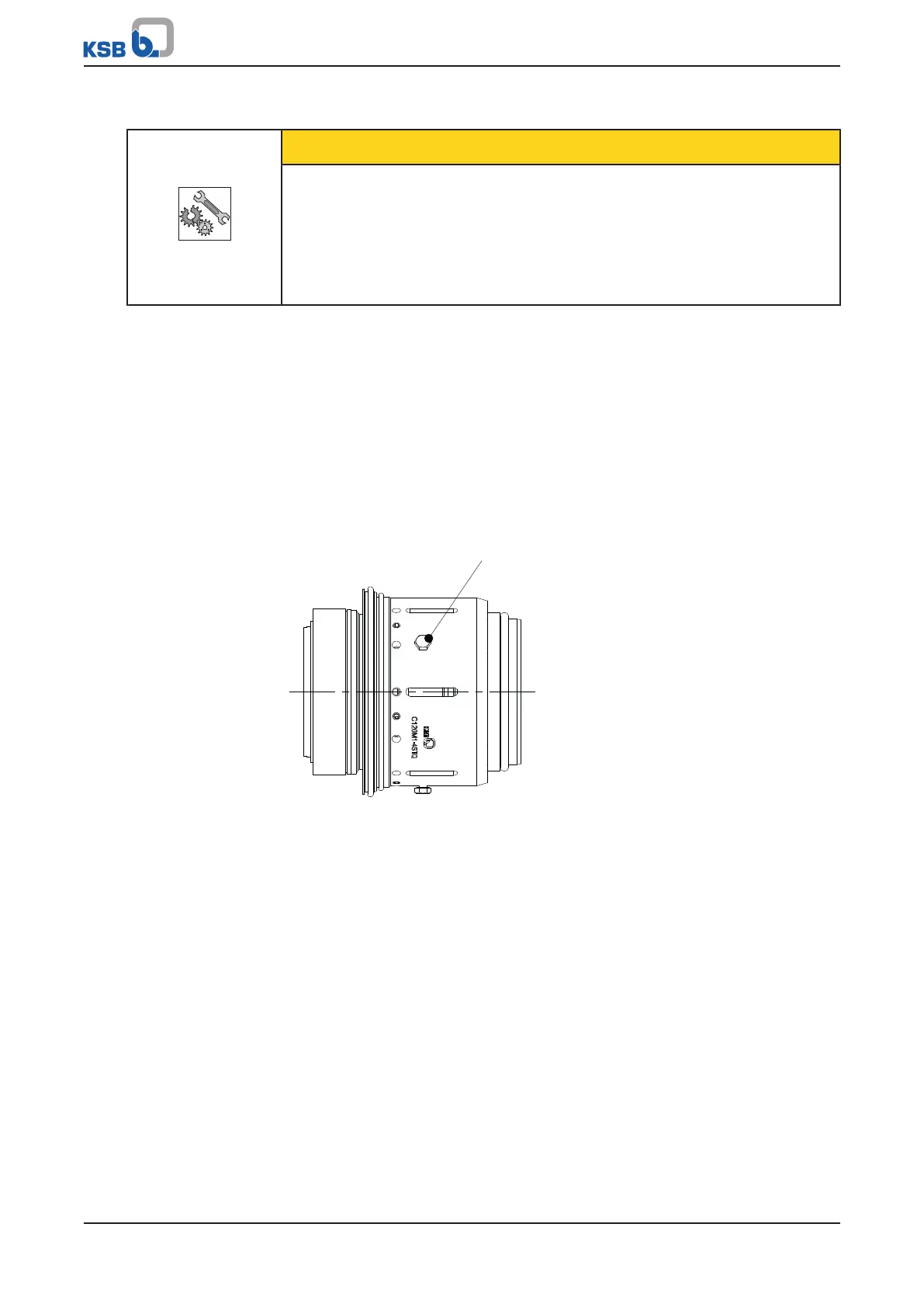

Fig.11: Illustration showing hexagon head bolt

4. Completely remove the hexagon head bolts901 (x 3) that make up the transport

lock and store them.

5. Apply a coat of a suitable grease to shaft210 in the area of the mechanical seal

and the impeller hub.

6. Align the groove in shaft sleeve 523 with the groove in shaft210.

7. Carefully slide the entire cartridge mechanical seal 4STQ onto the shaft until seal

cover 471 abuts discharge cover 163. Apply the axial force required for insertion

into the discharge cover via the seal cover only. Ensure that primary ring472.52

and mating ring475.52 are not damaged. A tube with an inside diameter larger

than 170mm and outside diameter smaller than 190mm can be used to press

the stationary seal cover into the discharge cover of the pump.

8. Fit circlip 932.53 in the groove of discharge cover 163. Make sure it is correctly

seated.

Loading...

Loading...