ENGLISH

30

Part-throttle range C

Operation with partly open throttle valve. This range is only influenced by

the jet needle (shape and position). The optimum part-throttle setting is

controlled by the idling setting in the lower range and by the main jet in the

upper range. If the engine runs on a four-stroke cycle or with reduced

power when it is accelerated with the throttle partly open, the jet needle

must be lowered by one notch. If then the engine pings, especially when

accelerating under full power at maximum engine revs, the jet needle

should be raised.

If these faults should occur at the lower end of the part throttle range at a

four-stroke running, make the idling range leaner; if the engine pings,

adjust the idling range richer.

Full throttle range D

Operation with the throttle fully open (flat out). This range is influenced by

the main jet and the jet needle. If the porcelain of the new spark plug is

found to have a very bright or white coating or if the engine rings, after a

short distance of riding flat out, a larger main jet is required. If the porce-

lain is dark brown or black with soot the main jet must be replaced by a

smaller one.

Powerjet (250 SX)

A magnetic valve, the Powerjet nozzle, is opened when maximum torque

has been reached during acceleration, i.e. at between 6,800 – 8,500 rpm.

This sends additional petrol through the carburettor. If the engine is too fat

a smaller Powerjet nozzle must be fitted. If the engine is too lean a larger

Powerjet nozzle must be fitted.

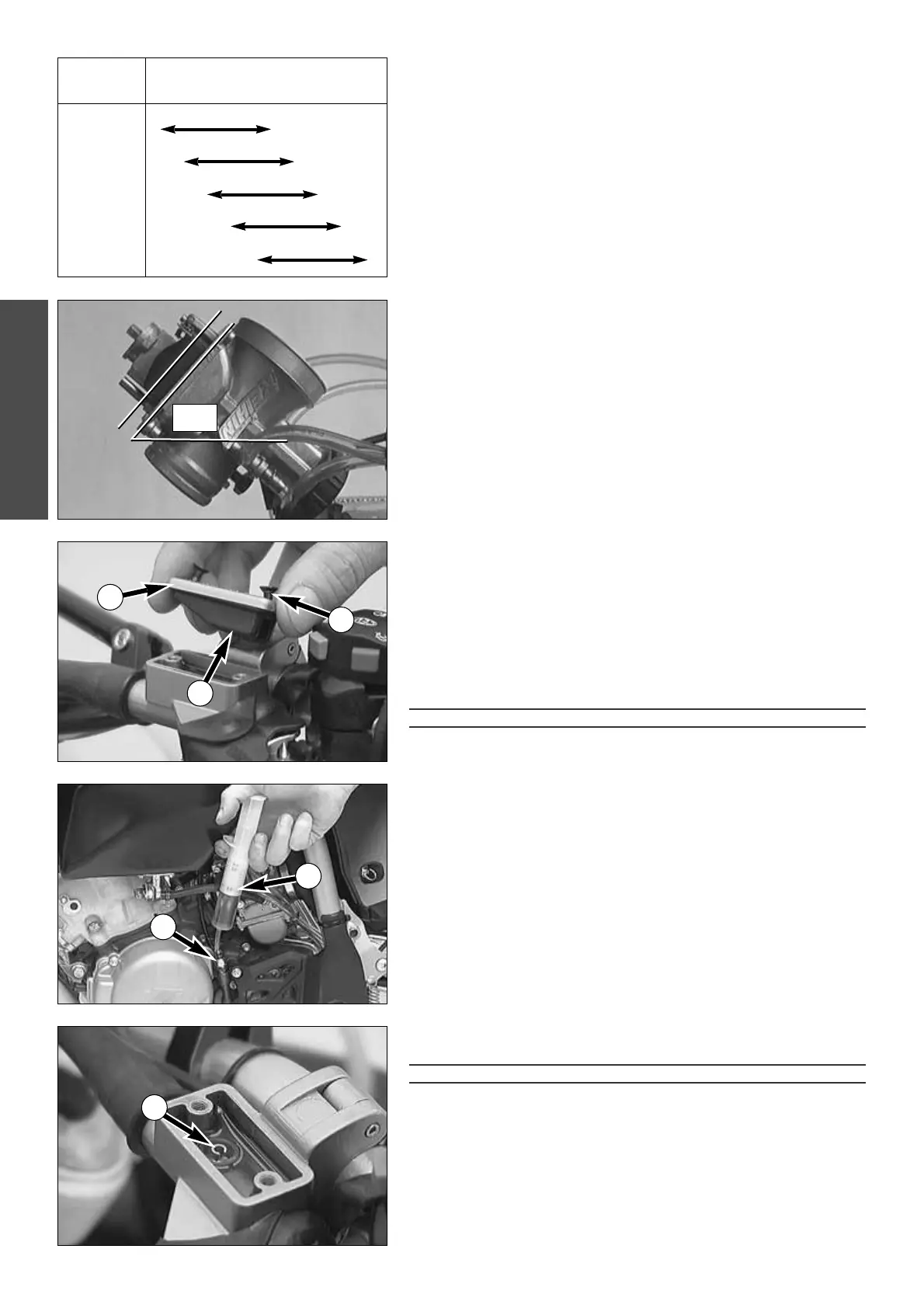

Checking the float level *

Arrange the carburetor diagonally at about 60° so that the spring in the

float needle valve is not pressed together. In this position, the edge of

the

float should be parallel with the float chamber sealing surface (see

illustration).

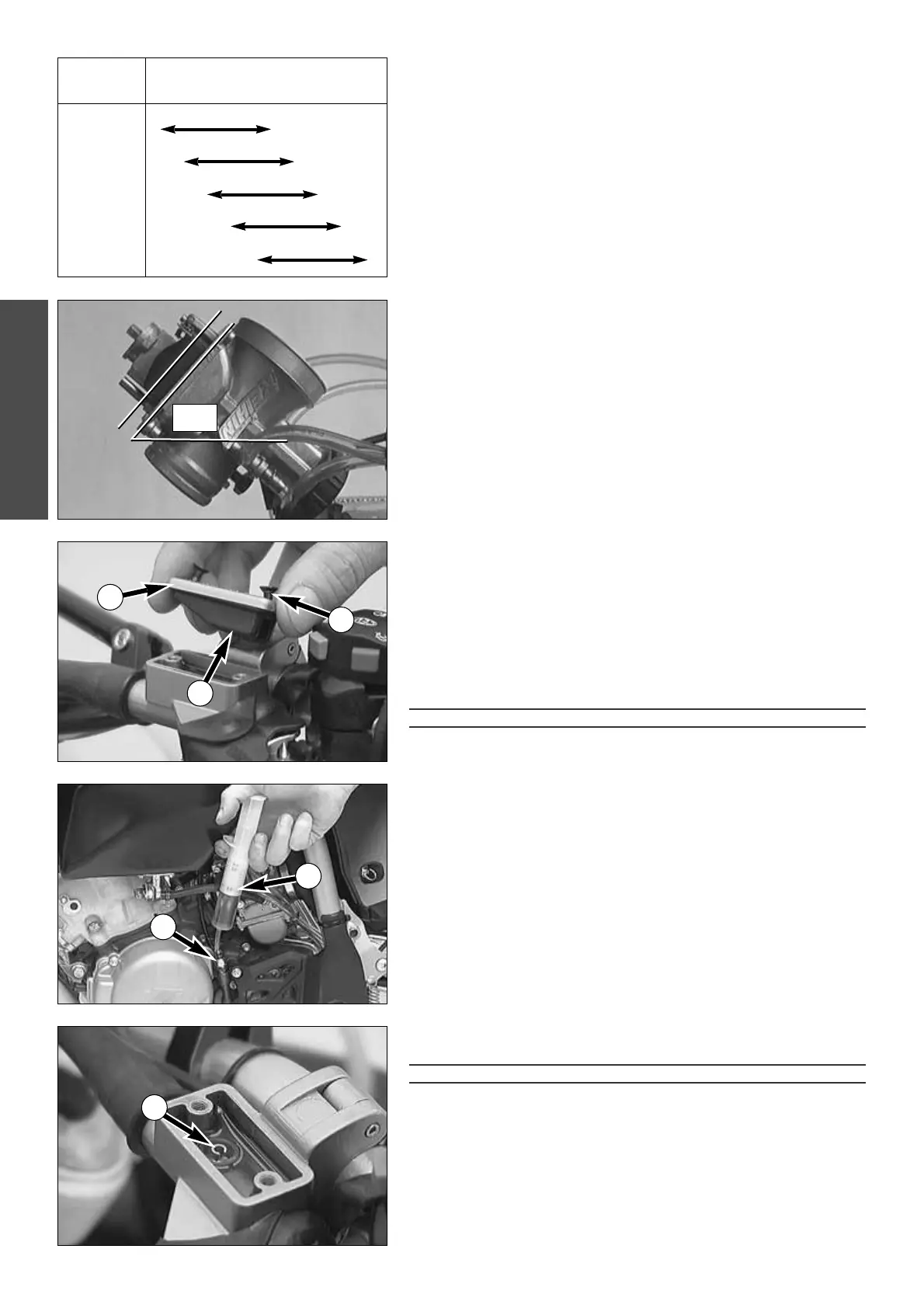

Checking the oil level of the hydraulic clutch

To check the oil level in the master cylinder of the clutch remove the

cover. For this purpose, remove screws

1 and cover 2 together with

the rubber boot

3. The oil level in the horizontal-standing master cylin-

der should be 4 mm below the upper edge. If necessary add SAE 10

hydraulic oil

!

CAUTION

!

O

NLY USE SAE 10

MINERAL HYDRAULIC OIL (i.e. Shell Naturelle HF-E15) TO REFILL

THE MASTER CYLINDER

. NEVER USE BRAKE FLUID!

Bleeding of the hydraulic clutch

For bleeding, the cover of the master cylinder of the clutch needs to be

removed. For this purpose, remove screws 1 and take off cover 2 together

with rubber bellows

3. At the slave cylinder of the clutch, remove the blee-

der nipple 4. At its place, mount the bleeder syringe 5 which is filled with

SAE 10 hydraulic oil. Refill oil, until oil is discharged from the bore

6 of the

master cylinder in a bubble-free state. Make sure that the oil does not over-

flow. The bleeder syringe can be purchased at your KTM dealer.

!

CAUTION

!

H

AVING COMPLETED THE BLEEDING PROCEDURE, YOU HAVE TO VERIFY THAT THE OIL

LEVEL IN THE MASTER CYLINDER IS CORRECT

. FOR FILLING OF THE MASTER CYLINDER, USE

SAE 10

MINERAL HYDRAULIC OIL (e.g. Shell Naturelle HF-E15) ONLY; NEVER USE

BRACKE FLUID

!

NOZD

NOZE

NOZF

NOZG

NOZH

JET NEEDLE

RANGE OF ACTION

TYPE RICHER LEANER

60°

1

2

3

6

4

5

Loading...

Loading...