18

ENGINE

182

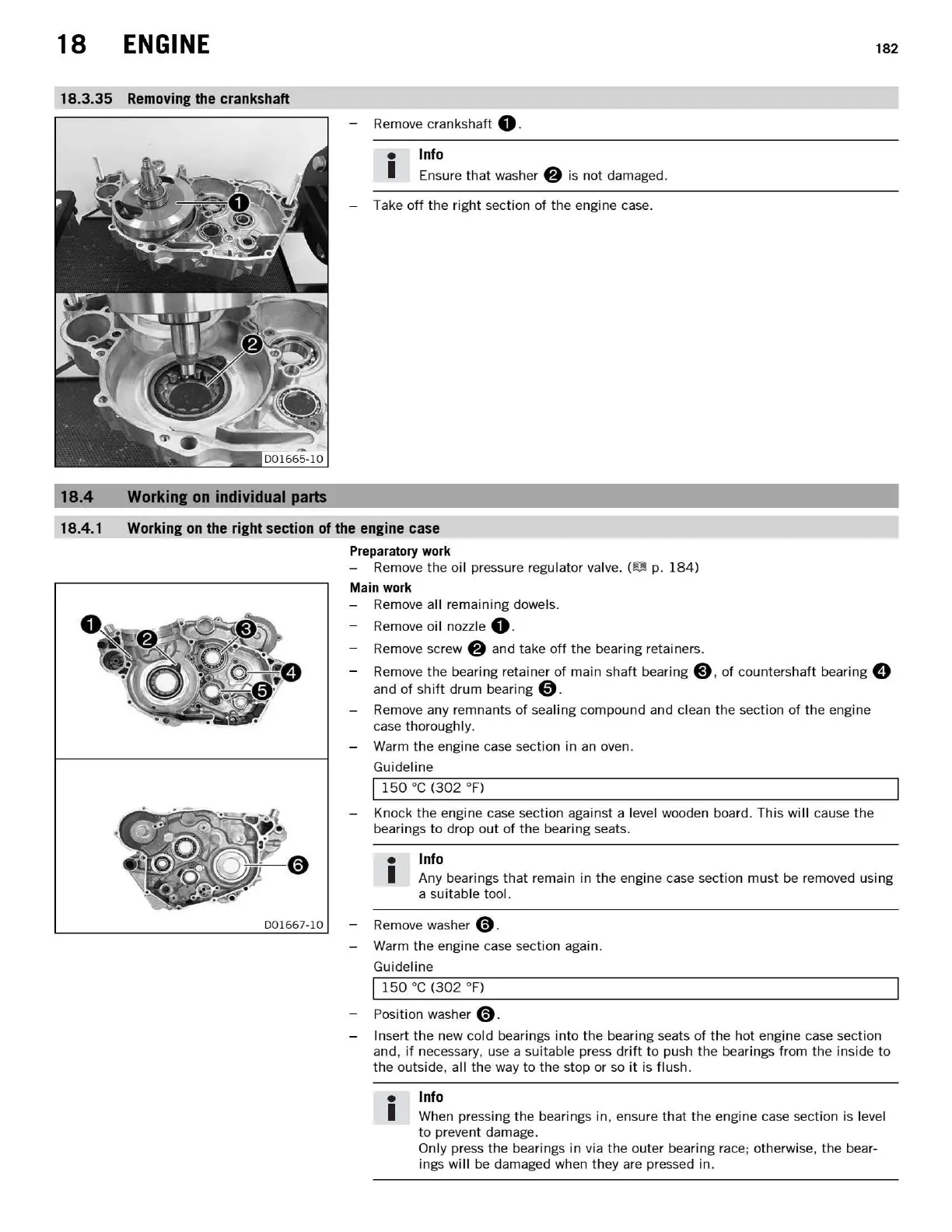

18.3.35

Removing the crankshaft

18.4

18.4.1

Remove cra

nk

s

haft

0 .

• Info

I Ensu

re

that

washer 8 is

not

damaged.

Take

off

the

right

section of

the

engine case.

Working

on

individual

parts

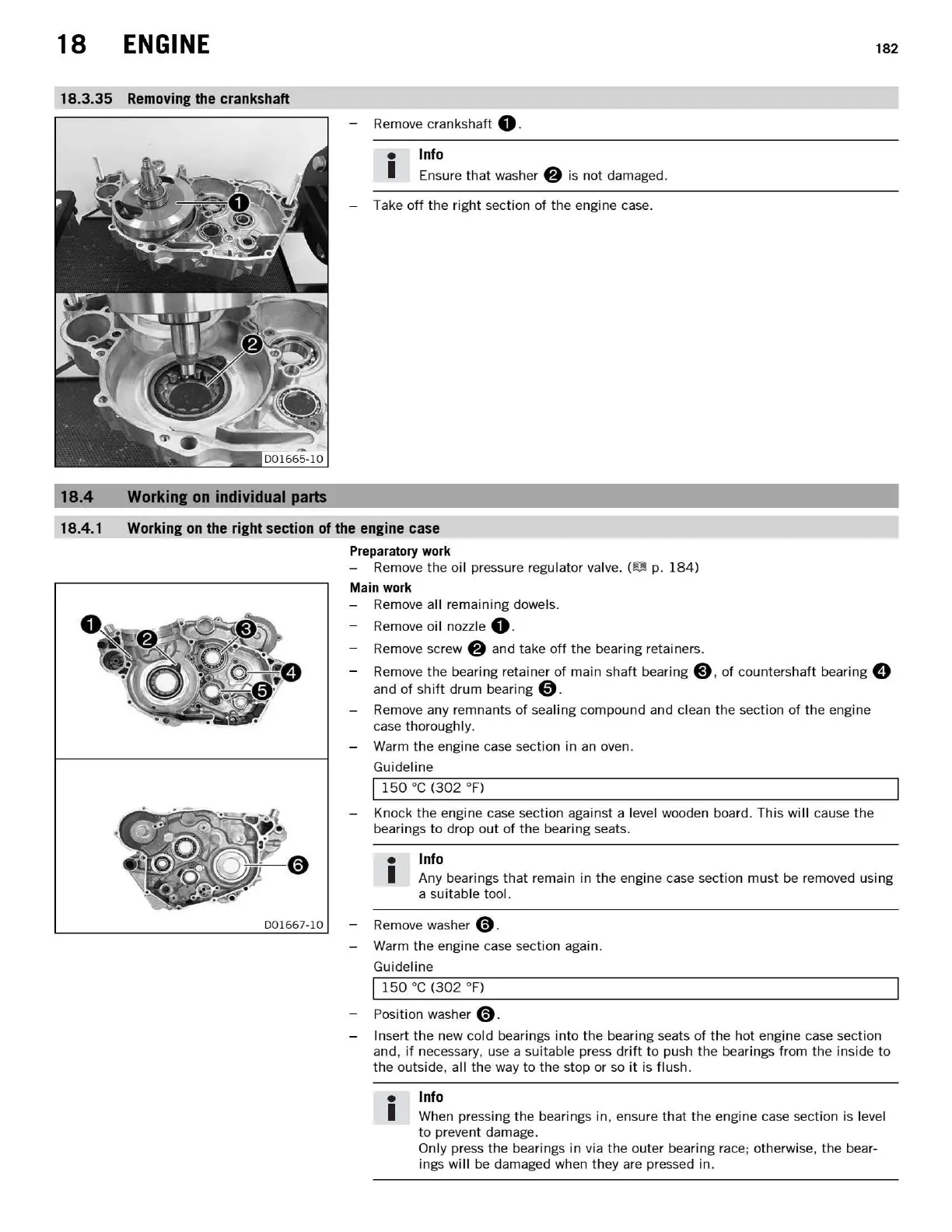

Working

on

the right section of the engine case

Preparatory

work

0016

67

-10

Remove the oil pressure regulator

va

l

ve.

(

lg

p.

184)

Main

work

Remove all remaining dowels.

Remove oil nozzle O .

Remove screw 8 and take

off

the

bearing retainers.

Remove the bearing retainer

of

main s

haft

bearing

@)

, of counters

haft

bearing 8

and

of

s

hift

drum

bearing 0 .

Remove any remnants of sealing compound and clean the section

of

the engine

case

thoroughly.

Warm

the

engine case section in

an

oven.

Guideline

1

150

oc

(302

°

F)

Knock the engine case section against a

le

ve

l wooden board. This

will

cause the

bearings to drop

out

of

the

bearing seats.

• Info

I Any bearings

that

remain in

the

engine case section

mu

st

be removed using

a suitable tool.

Remove washer 0 .

Warm

the

engine case section again.

Guideline

I

150

oc

(302

°

F)

Position washer 0 .

Insert

the

new cold bearings

int

o the bearing seats

of

the

hot

engine case section

and,

if

necessary, u

se

a su itable press

drift

to

push

the

bearings from

the

inside

to

the outside, all

the

way

to

the

s

top

or

so

it

is flush.

• Info

I When pressing

the

bearings in, ensure

that

the

engine case sec

tion

is level

to

pre

ve

nt

damage.

On

ly pre

ss

the

bearings in via the outer b

ea

ring race; otherwise, the bear-

ings

will

be

damaged when they are pressed in.

Loading...

Loading...