12. Checking gauges, meter and

Easy Checker

™

1. Inspect

the instrument panel for broken gauge(s),

meter(s) and Easy Checker

™

indicators.

2. Replace if broken.

13. Checking headlight, hazard light,

and so on

1. Inspect the lights for broken bulbs and lenses.

2.

Replace if broken.

14. Checking seat belt and ROPS

1. Always

check the condition of the seat belt and

ROPS attaching hardware before operating the

tractor.

2. Replace if damaged.

15. Checking and cleaning of

electrical wiring and battery cables

WARNING

T

o avoid personal injury or death:

• A loose terminal or connector, or a damaged

wire may affect the performance of the electrical

components or cause short circuits. Leakage of

electricity could result in a fire hazard, a dead

battery or damage to electrical components.

• Replace the damaged wires or connections

promptly.

• If a fuse blows soon after replacement, do not

use a larger than recommended fuse or bypass

the fuse system.

• Many wiring connections are protected by

waterproof plugs. Plug and unplug these

connections carefully and make sure they are

sealed correctly after assembly.

• Accumulation of dust, chaff or spilled fuel

deposits around the battery, electrical wiring,

engine or exhaust system may cause a fire

hazard. Clean these areas before starting the

work.

To avoid the premature electrical

malfunctioning, do not apply high pressure

water directly to battery, wiring, connectors,

electrical components or instrument panel.

Inspect the following regularly

1.

Check the wiring for chafed or cracked insulation.

2. Check the wiring harness clamps. Replace if

necessary.

3. Check

the connectors and terminals for looseness,

contamination or overheated (discolored)

connections.

4. Check the instrument panel for correct operation of

the switches and gauges.

Consult your KUBOTA Dealer regarding maintenance,

diagnosis and repair

.

16. Checking movable parts

If any of the movable parts, such as levers and pedals,

are

not moving smoothly because of rust or sticky

material, do not attempt to force them into motion.

In the above case, remove the rust or the sticky

material and apply oil or grease to the relevant spot.

Otherwise, the machine may be damaged.

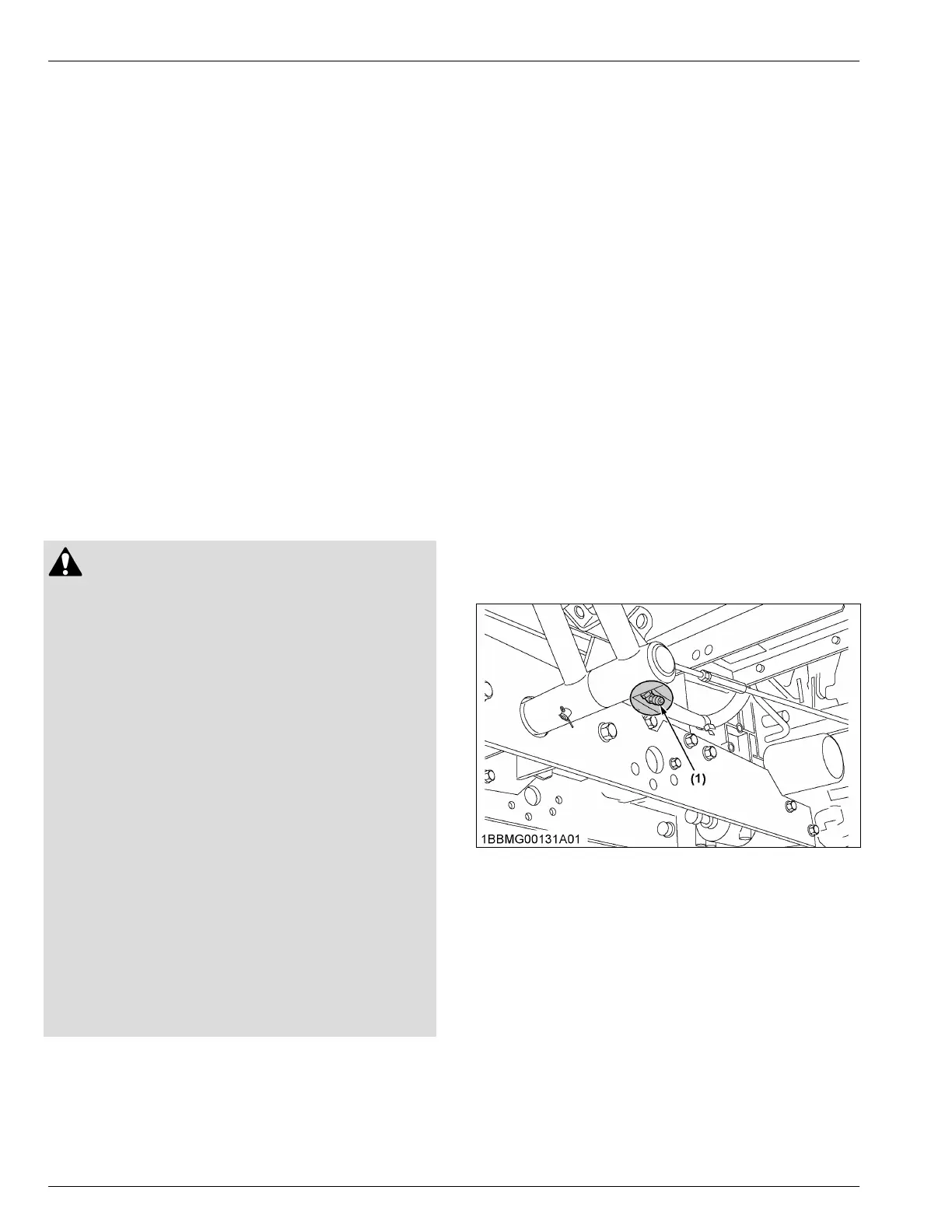

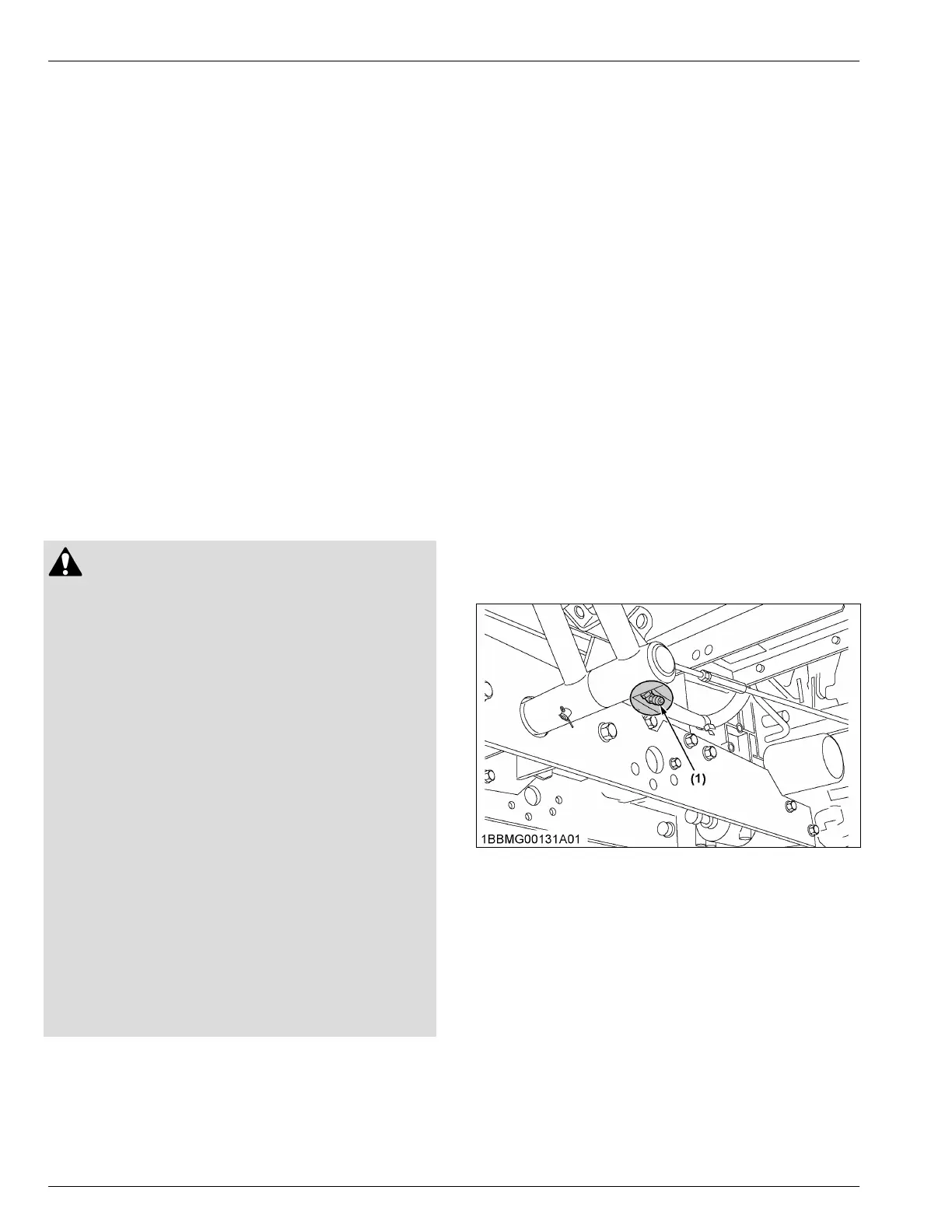

EVERY 50 HOURS

1. Lubricating grease fittings

Apply a small amount of multipurpose grease to the

following points every 50 hours.

If

you have been operating the machine in extremely

wet and muddy conditions, lubricate the grease fittings

more often.

ROPS model

(1) Grease fitting (brake pedal)

PERIODIC SERVICE DAILY CHECK

Loading...

Loading...