Instructions for work

Power harrow

HR6004DR

47

2. Adjustments in working position

Rigid/floating working position.

The machine can operate in two ways:

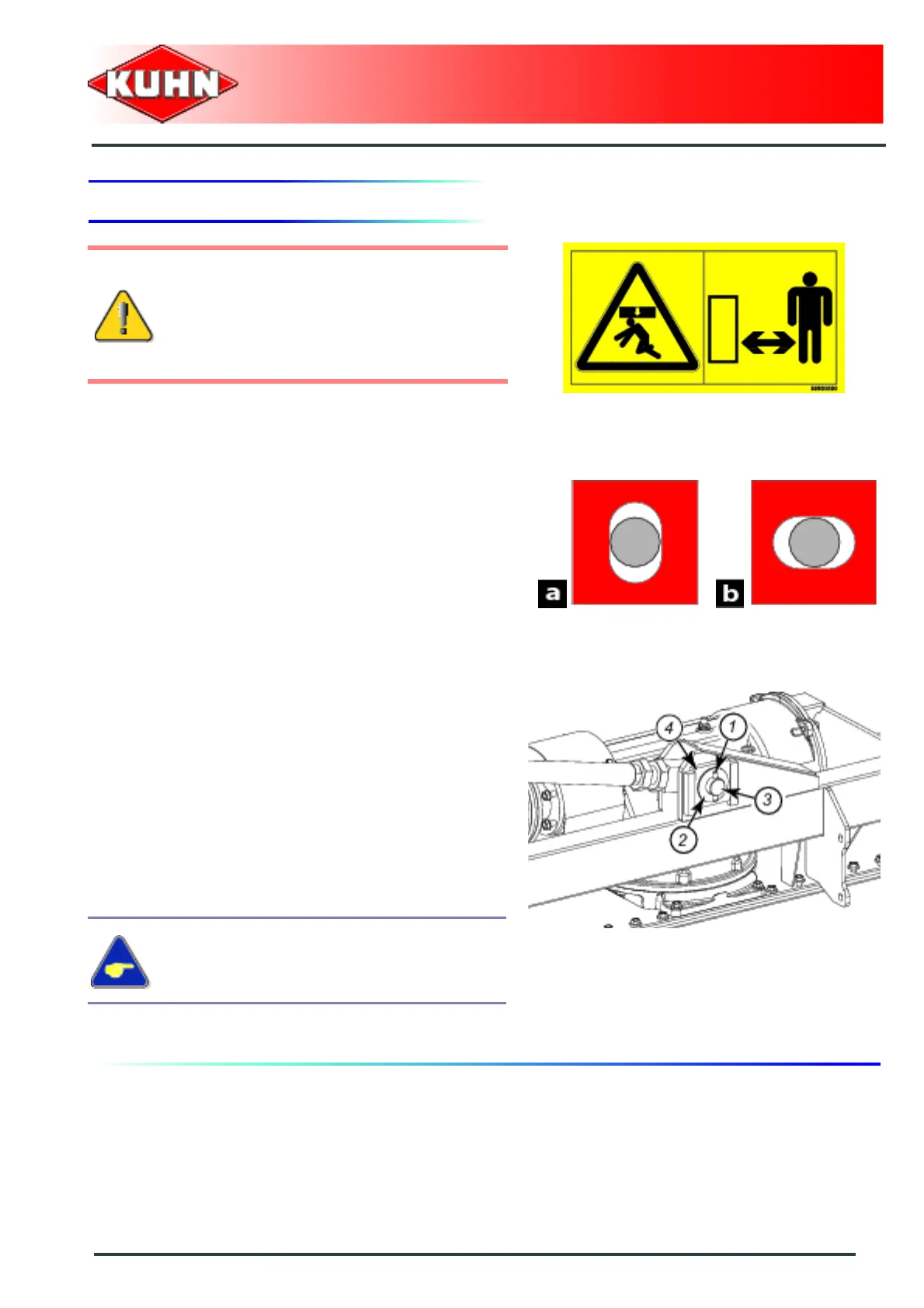

Rigid position: (a)

The half-harrows are locked on the frame and work like

a rigid harrow: Improved soil levelling.

Floating position: (b)

The half-harrow outboard sides have a travel range of -

100 mm to approximately +100 mm (-4’’/+4’’): The

floating position provides contour following on irregular

ground.

The machine is factory set in rigid position.

Setting to floating position:

- Remove roll pin (1) and washer (2).

- Check that the pin is not under load: If necessary,

activate transport/work cylinder control valves of the

half-harrows to free pin.

- Remove pin (3).

- Remove and rotate square spacers (4) through 90° to

bring the slot to a horizontal position.

- Reinstall pin (3).

- Reinstall washer (2) and roll pin (1).

- Repeat procedure on the second half-harrow.

The machine is in floating position.

Reverse the sequence to put the slot in vertical position

and the machine in rigid position.

Before placing the machine in working

position:

- Check that nobody is within the machine

pivoting area.

- If there is someone, make sure the

person moves away.

The two half-harrows must be in the same

working position.

Loading...

Loading...