Power harrow

82

HR6004DR

Trouble shooting guide

$Trouble shooting guide

-

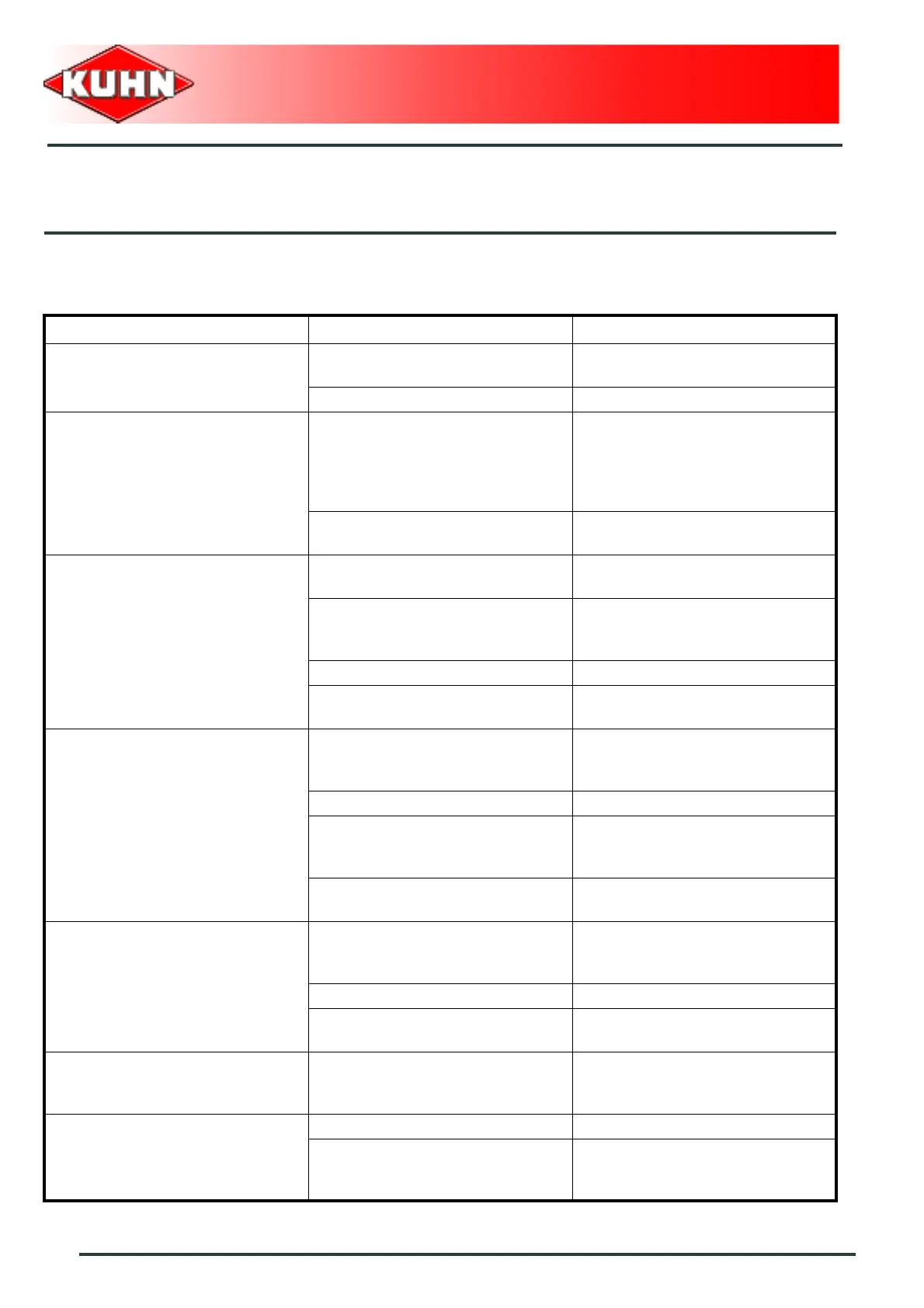

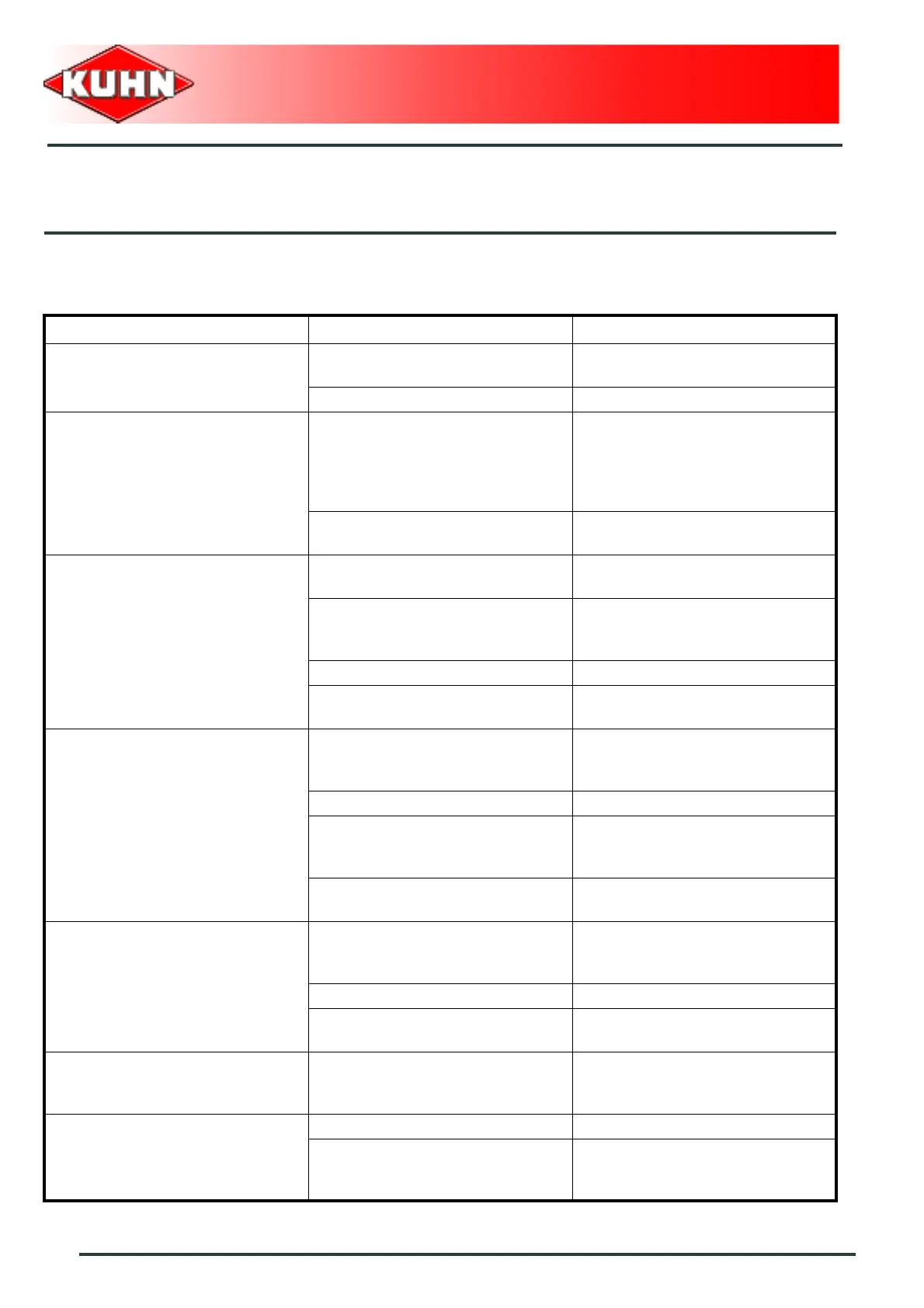

Problem Cause Remedy

Noisy drive when lifting the

machine

Top link of 3-point hitch badly

positioned/adjusted

Position top link parallel to

lower linkage arms

Excessive lifting height Limit the lift linkage stroke

Noisy drive during work

Machine tilted to the front or

rear (excessive pitch angle)

Lengthen or shorten top link to

set the machine horizontally

during work. (Tractor pto shaft

end and machine input shaft

must be parallel)

Insufficient machine side to

side stabilization

Use lower linkage arm

stabilizers

Excessive power requirement

Working depth too deep

Reduce working depth by

adjusting the roller height

Rotor speed too high

Reduce speed using the side

gearboxes. (optional

gearwheel sets)

Excessive ground speed Reduce ground speed

Incorrect setting of the rear

levelling bars

Raise or remove the levelling

bars

Tilth produced is too coarse

Considerable build-up of long

plant residues around the

blades

Eliminate plant residues

Excessive ground speed Reduce ground speed

Rotor speed too low

Increase speed at the side

gearboxes (optional gearwheel

sets)

No levelling bars

Install levelling bars, preferably

towards the rear

Tilth produced is too fine

Rotor speed too high

Reduce speed using the side

gearboxes. (optional

gearwheel sets)

Forward speed is too slow Increase forward speed

Rear levelling bars are too low

Raise or remove the levelling

bars

Ridging at the side of the

machine

Anti-ridging plate incorrectly

positioned on the side

deflectors

Position each anti-ridging plate

as close as possible to the

ground and roller

Excessive wear on blades and

blade holders

PTO speed is too high Reduce PTO speed

Levelling bars mounted at the

rear

Remove rear levelling bars if

not required by working

conditions

Loading...

Loading...