Power harrow

64

HR6004DR

Maintenance and storage

3. Lubrication

Except for the secondary PTO shaft lubrication, the

machine must be placed in transport position for all

maintenance operations.

Clean grease nipples before greasing.

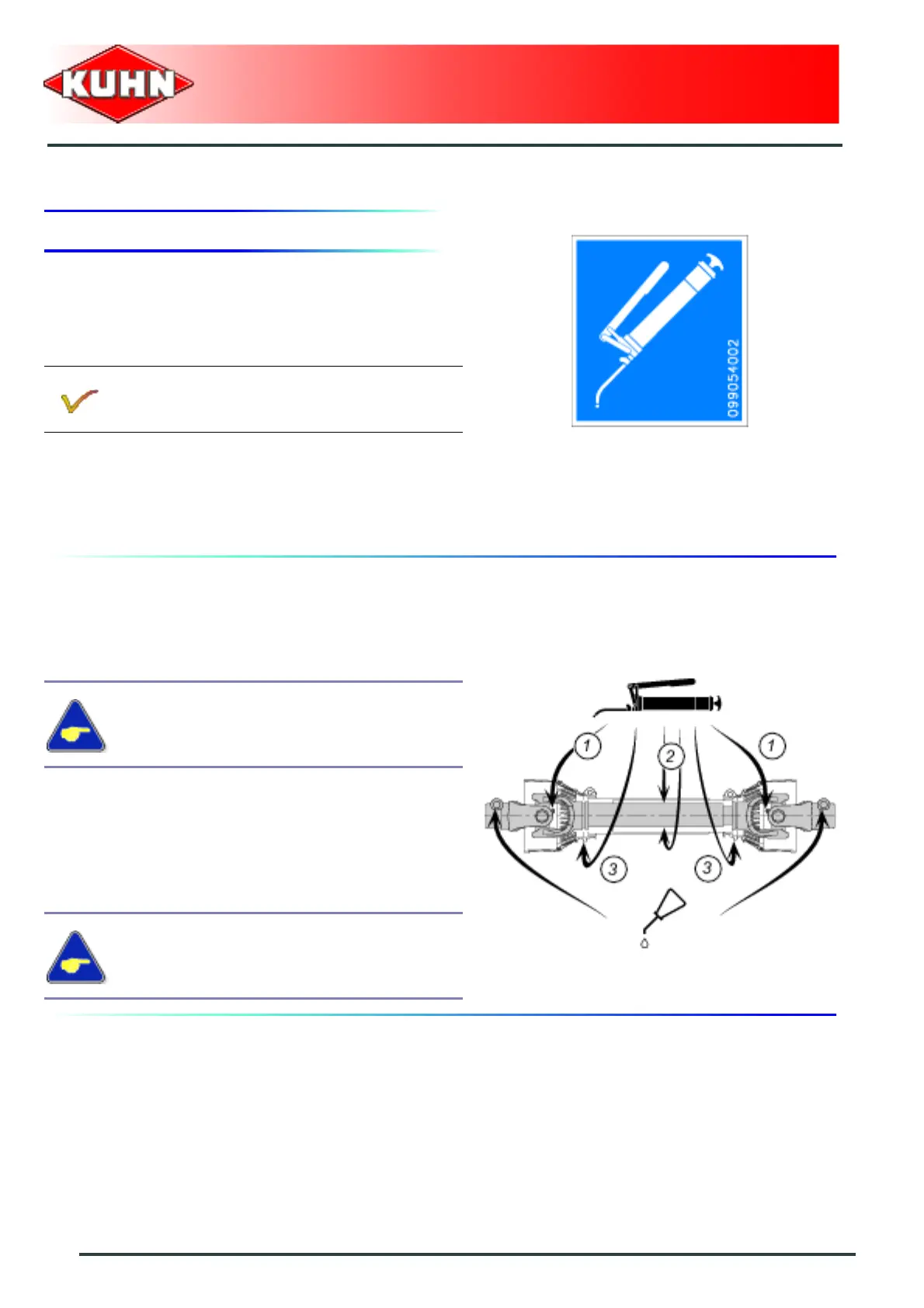

Intermediate PTO shaft 1

Every 250 hours or at the end of the season:

- U-joints (1).

- Transmission tube:

- guide rings (3):

• Unlock and slide guards for easier greasing of the

PTO shaft u-joints and guiding bushes.

Each time the 2 half-PTO shafts are split:

- Transmission tube (The two grease nipples (2)).

Lubricate with SHELL multi-purpose grease

grade NLGI 2.

To access the 2 grease nipples (2) to grease

(Slide the black collar).

During intensive use with tractors of

maximum authorized power, it is

recommended to grease at closer intervals

(Interval of 100 to 150 hours).

Loading...

Loading...