23 44

EN

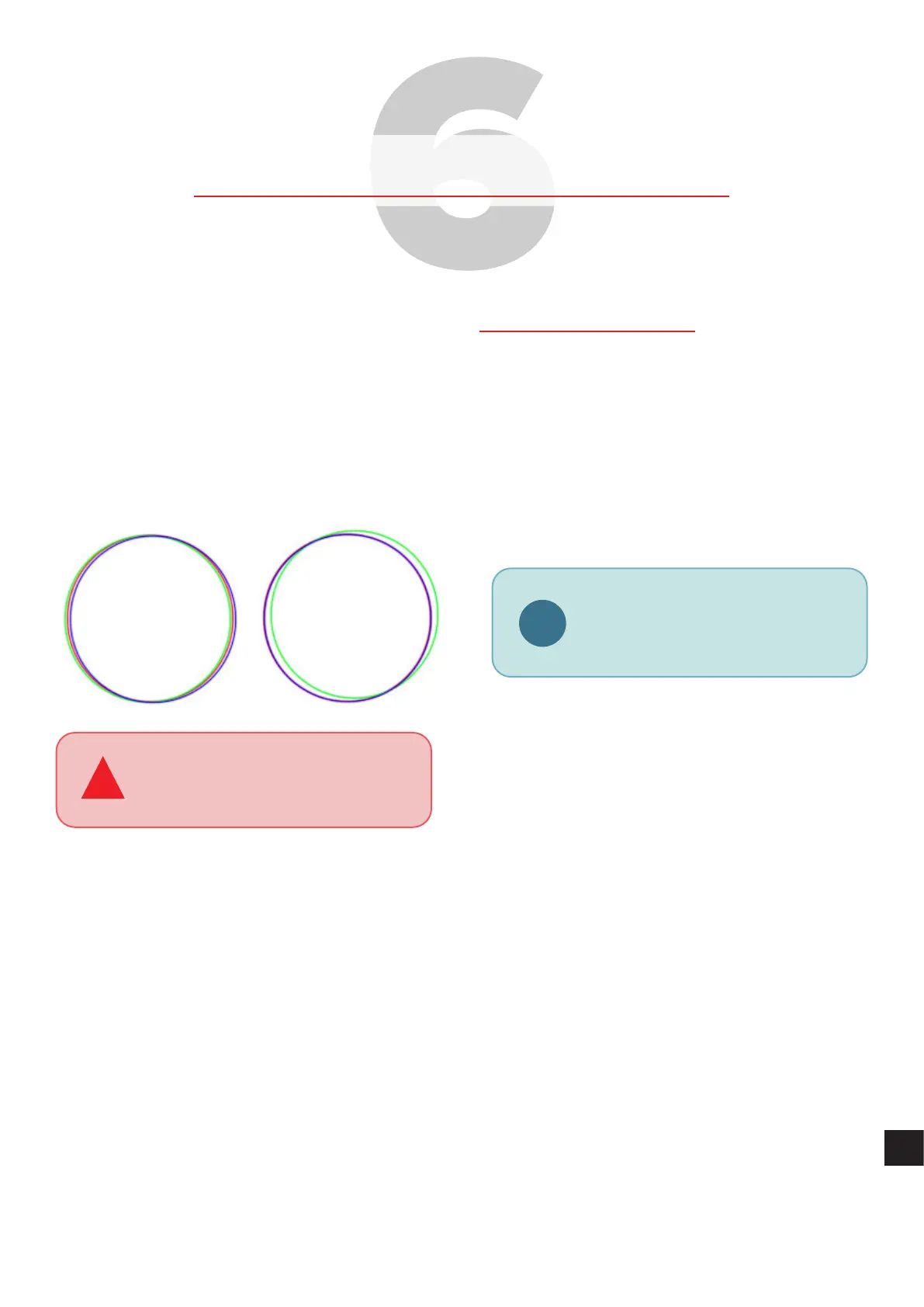

It is possible that due to transportation, rigging, moving

around or vibrations caused by various elements during

aset uporlaser performance some ofthe internal optical

parts can move slightly resulting incolour misalignment.

The colour misalignment is when two or more colours

(red, green and blue) physically donot overlay each other

properly like onthe picture below. This makes itimpossible

toget nicely mixed colours like yellow, cyan, magenta and

white (including all their shades). Ifthis occurs itisnecessary

tocarry out the beam alignment procedure.

!

Becautious when aligning the beams and

wear sucient laser safety protection

to avoid accidental exposure to Class

4laser radiation.

Beam alignment principle

There are three laser modules within this system where

each module produces one ofthe basic RGB colours (red,

green orblue).

The goal ofthe alignment procedure is toalign all three

beams (colours) so they overlay each other nicely while

they hit exact centre ofthe bottom scanning mirror.

An easiest way to do the alignment is to project a full

size circle onto awall (orany another suitable projection

surface), change its colour as necessary and check the

alignment ofindividual colours onboth Xand Yaxes.

i

Remember that greater isthe distance

between the laser system and the

projection surface during the alignment,

more precise the alignment will be.

When doing the alignment onlong distances itisalways

good tohave someone with you who can point you inthe

right direction. Alternatively you can use binoculars.

Loading...

Loading...