10

6 Operation

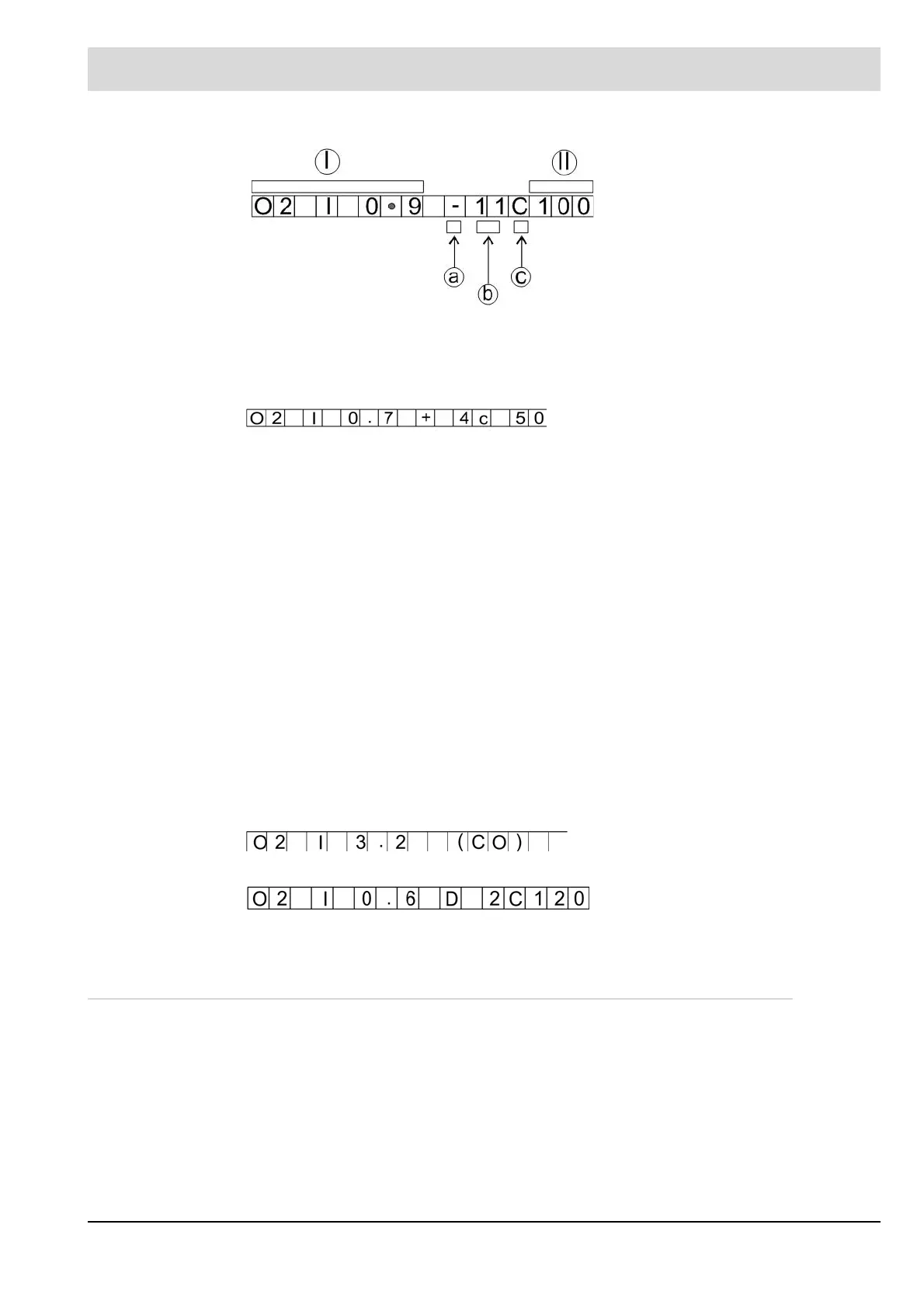

Examples:

Example of inactive control, if the O

2

controller is not permitted to take over.

Example of active dynamic test

D2 ... dynamic test active, CO

e

120 ppm

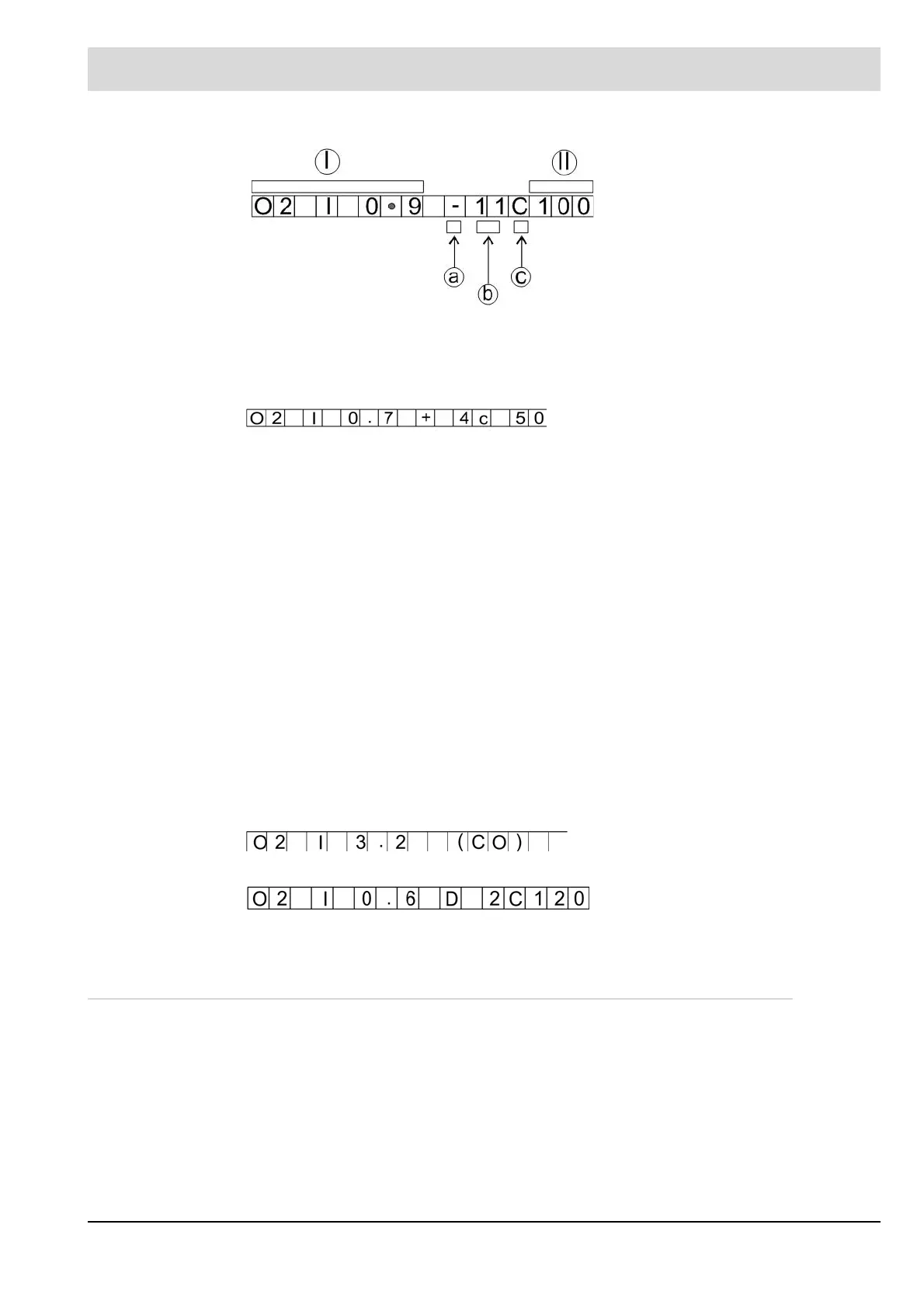

6.1.5 Display and Interpretation of the Operating Modes

I - O

2

actual value

II - CO

e

value

a Edge position:

"-" Air would be reduced

"+" Air would be increased

b11 11 optimisation steps have

taken place

c big "C" means optimisation dur-

ing increasing firing rate

small "c" means optimisation

during decreasing firing rate

O

2

actual value 0.7 %

+ air is increased, 4 optimisation steps already performed

c small "c" means optimisation in the learning curve for decreasing firing rat

e

CO

e

50ppm

b-

In

formation on optimisation in the

current

firing rate segment

"0" until now there were no optimi-

sation

"1" ... "31" linear approach

"32" optimisation completed

"50" ... "81" successive repeated control

from the CO

"D 1" ... "D 6" dynamic test step 1 to step 6

op O

2

trim in standby (during burner start-up), or O

2

trim temporarily switched off as a

function firing rate via parameters 914 and 915.

or O

2

- trim active.

ot O

2

trim temporarily deactivated (air deficiency, probe dynamics etc).

od O

2

trim deactivated (fault), e.g. test routine failed during burner start-up, dynamic test

negative, O

2

trim temporarily deactivated for over 1 hour etc.

C Optimisation at increasing firing rate

c Optimisation at decreasing firing rate

Loading...

Loading...