20

5 Maintenance

5 Maintenance

As a result of extensive self-diagnosis, the measuring system is essentially maintenance-free.

Maintenance is restricted to the calibration and the cleaning of dust or other deposits; as well

as the cyclic replacement of the ZrO

2

measuring element.

5.1 Probe Testing and Calibration

The checking / calibration has to be built (advantageously installed) in at normal operating

temperature and carried out under operating conditions.

Recommended time spans (cycles):

• 6 hours after commissioning

• 12 months for natural gas combustion systems

5.1.1 Checking/Calibrating the Air Voltage (Offset)

1. Shut down the system.

If the system cannot be shut down the probe must be removed from the system.

Respect the safety hints and warnings!

2. Pre-purge until there is no more flue gas at the measuring point (about 1 minute).

3. Finish pre-purge.

4. Perform the offset calibration of the O

2

(U-O2) electrode

see chapter 5.1.8.1 Offset Calibration perform to 21 % O

2

.

5.1.2 Checking/Calibrating the O

2

Electrode

See Chapter 5.1.10 Checking/Calibrating with Reference Measurement.

5.1.3 Reading the Measured Values

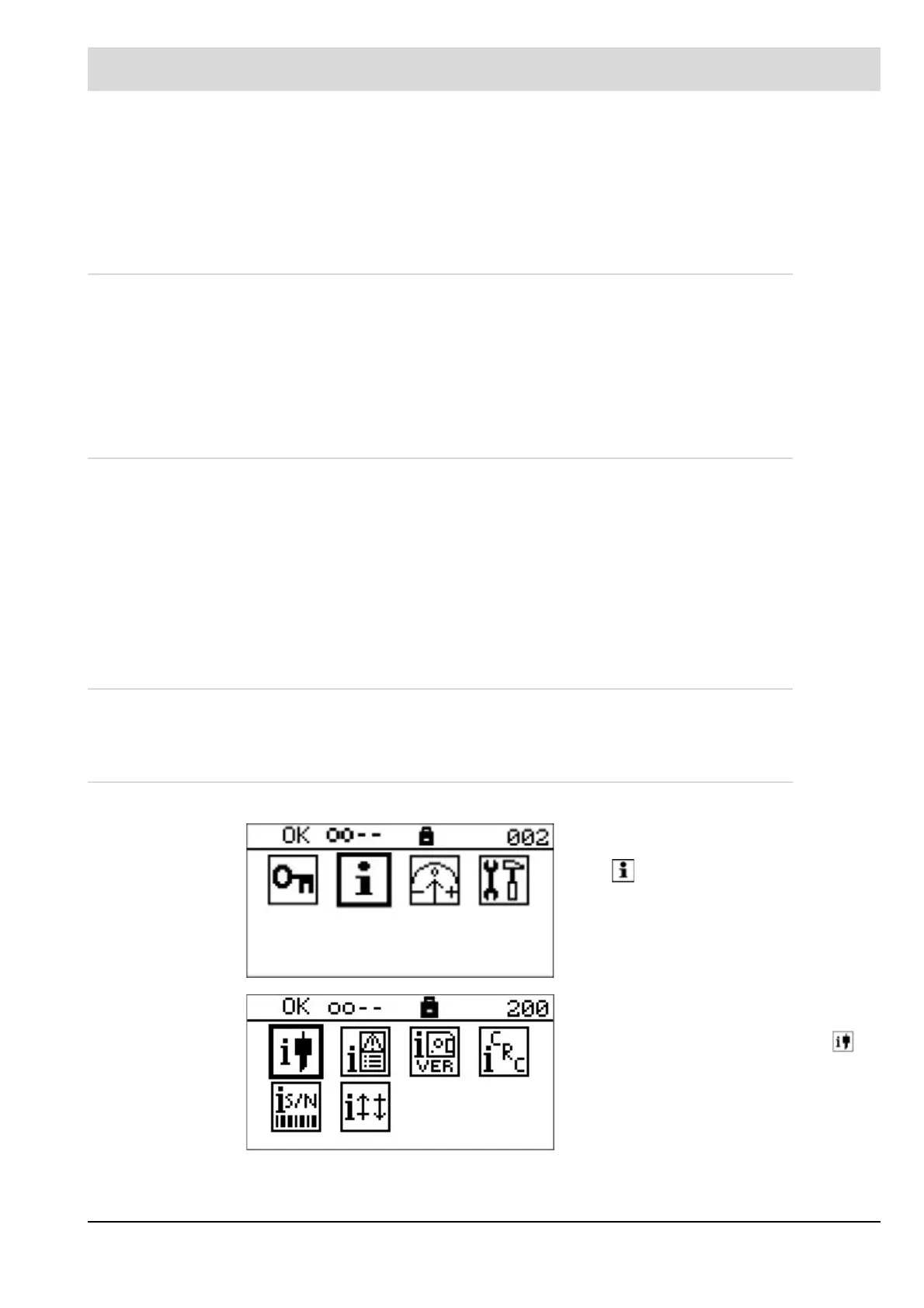

In the main menu, select the INFORMATION

menu .

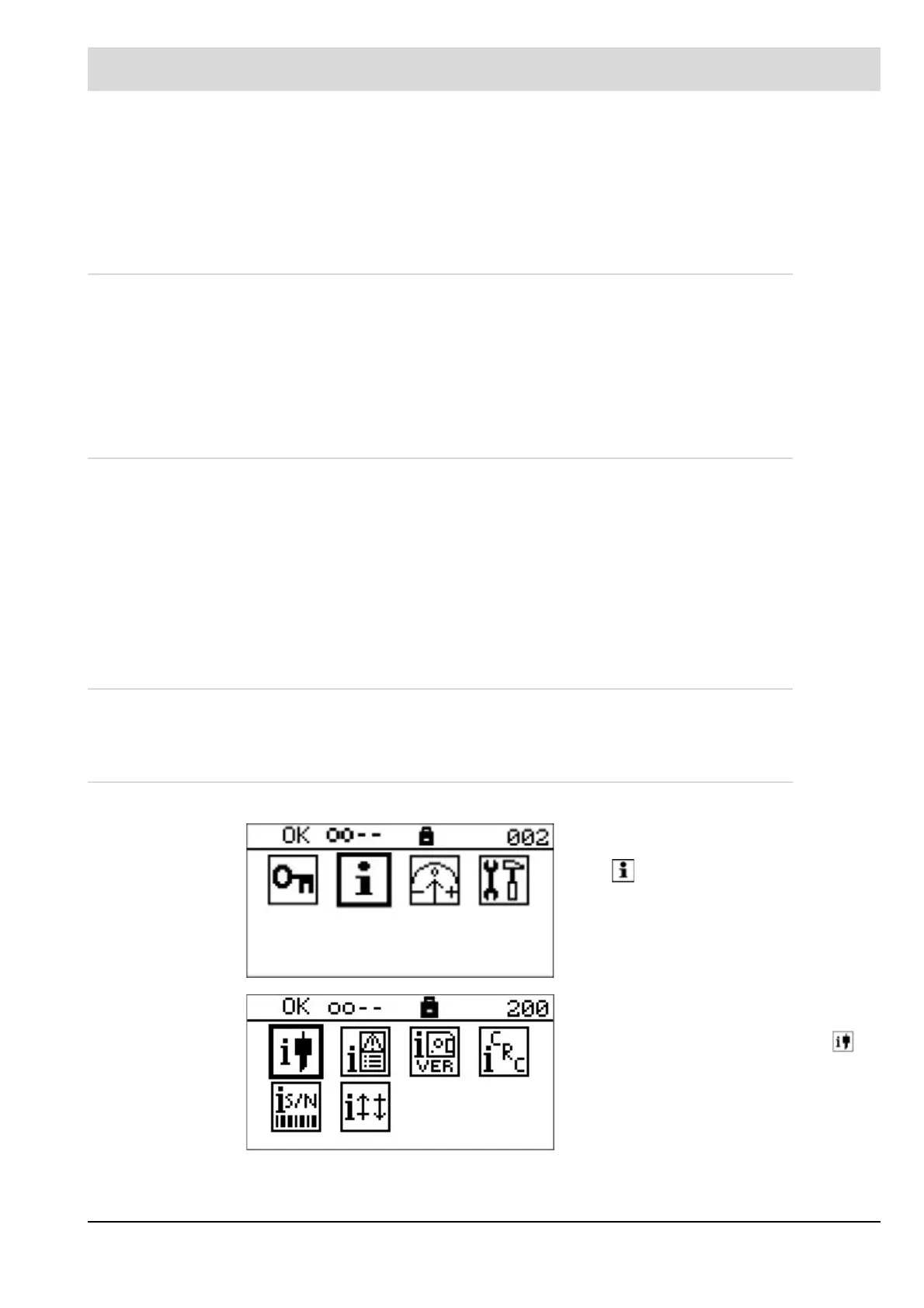

In the INFORMATION menu, select

measured values and probe data with .

Loading...

Loading...