38

- Check up the machine for completeness and its general condition.

- Any maintenance and servicing on the machine can be done at standstill only,

i.e. the PTO shaft off, the switch key being pulled out from the ignition box,

tractor wheels blocked against unwished motion.

- While servicing the chipper should be lowered on the ground.

- Pay special attention to all safety elements.

- Check up V-belts for tightness and wear.

- Keep regular intervals for lubrication of bearings.

- Check up condition of blades and chipping wheel vanes regularly.

- Check up hydraulic hoses for wear. Replace them if necessary or every five

years.

Lubrication

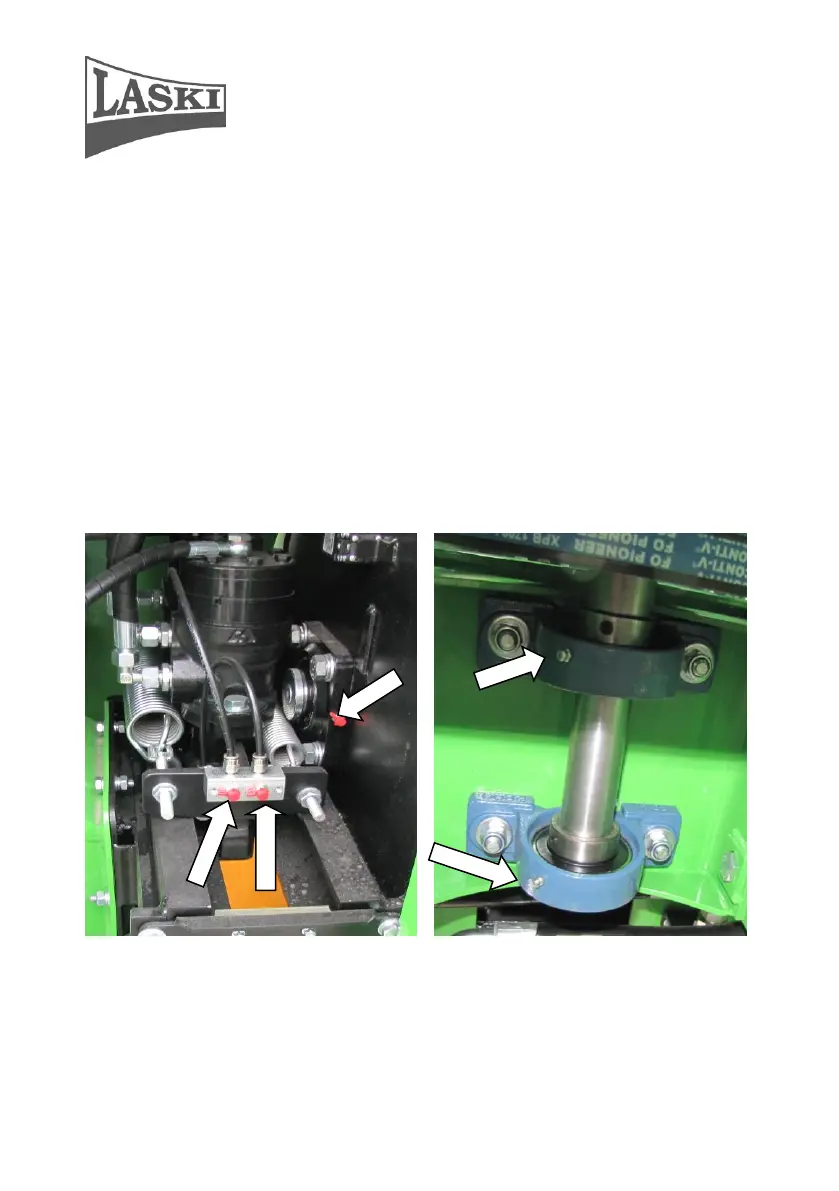

Grease cup of chipping wheel (left) and

sliding guides of loading rolls

Lubrication every 40 running hrs

(LTA 3EP MOL Lition)

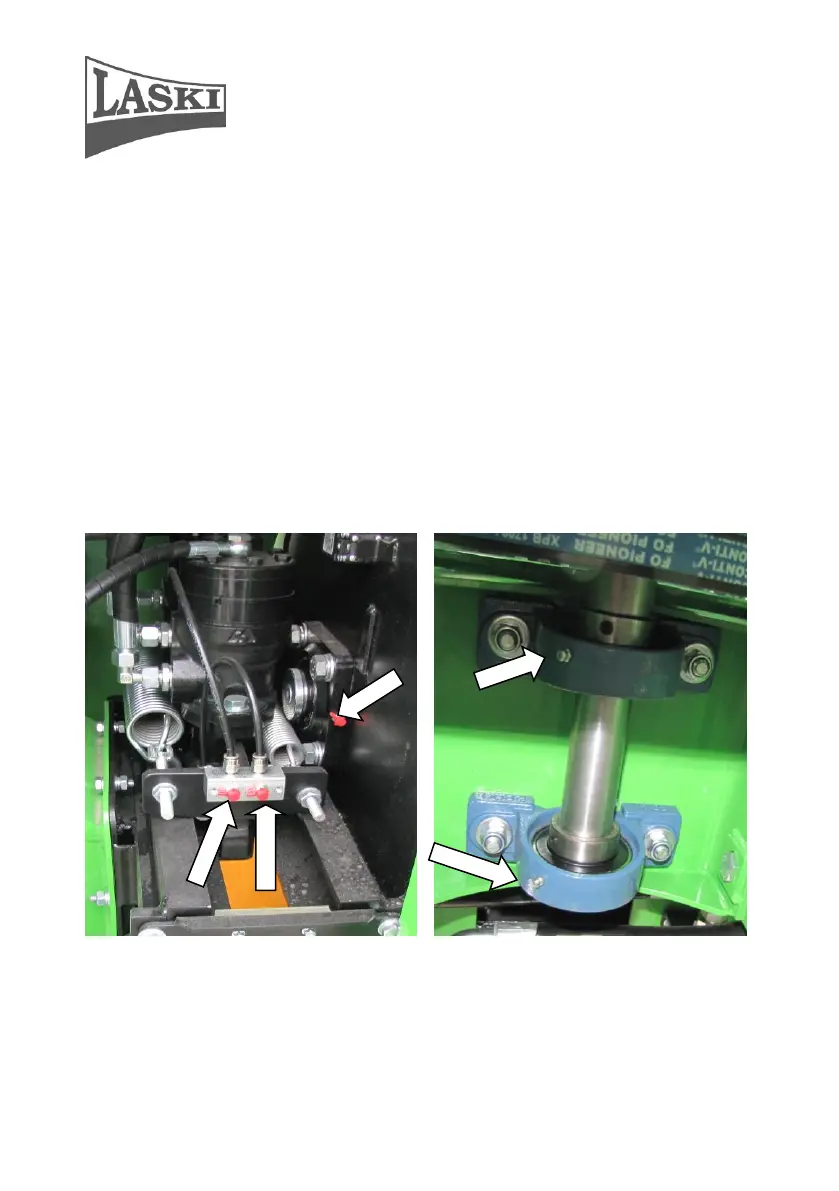

Grease cup on input shaft Lubrication

every 40 running hrs(LTA 3EP MOL

Lition)

Loading...

Loading...