39

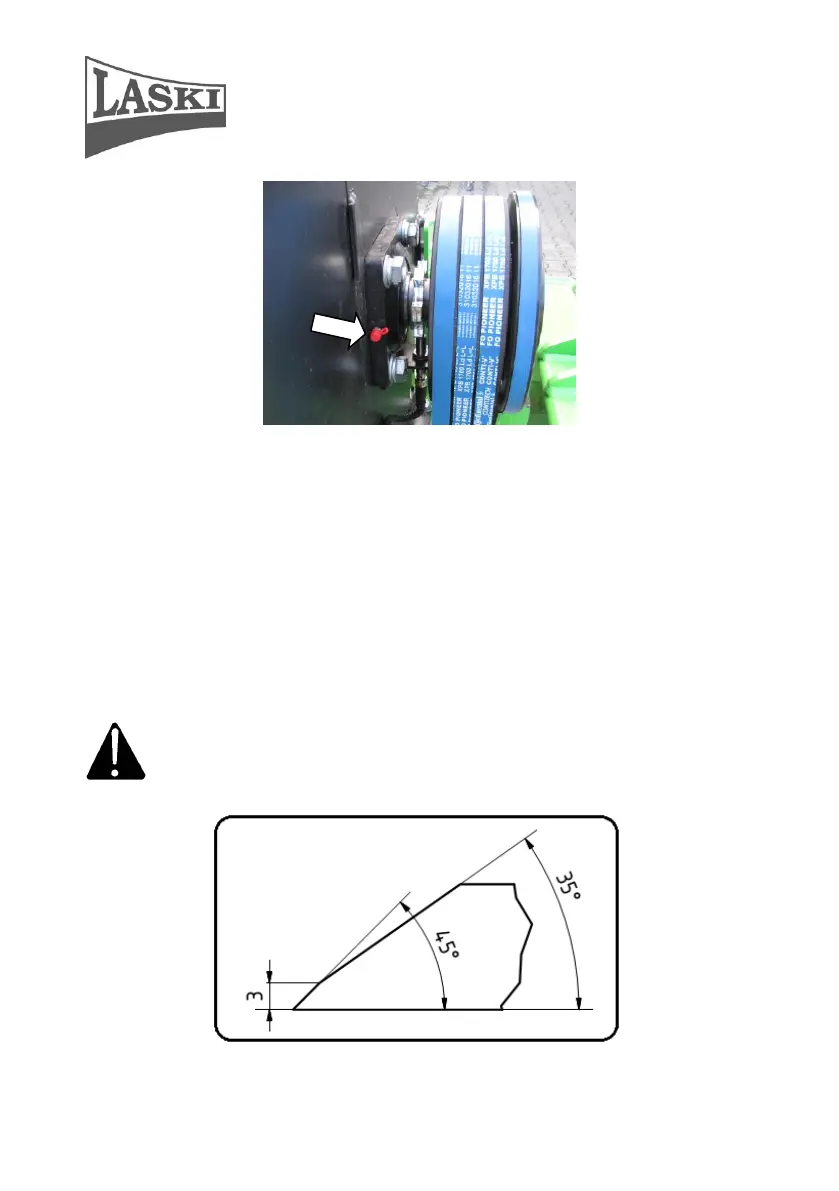

Grease cup of chipping wheel (right)

Lubrication every 40 running hrs(LTA 3EP MOL Lition)

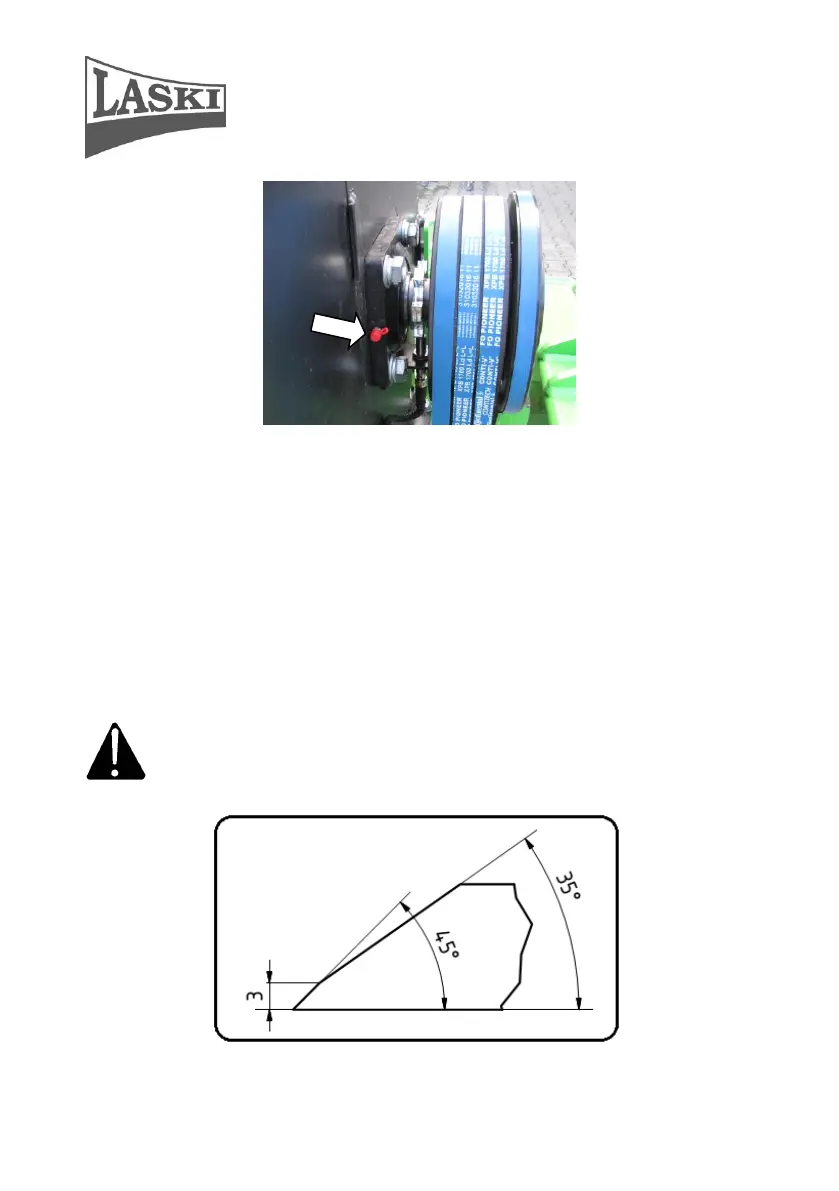

Blade Grinding

Blades, fitted on the chipping wheel, are double-sided, i.e. reversible if one side is

blunt.

Blades edge regrinding requires high demands for keeping cutting edge shape.

While grinding it is necessary to keep its optimal geometry, see following figure.

Proper shapes prolong blade service life.

While regrinding it is necessary to keep the same weight of particular

blades because of balance of their rotating mass. For grinding use

always a grinder with its magnetic table and a special jig.

Detailed geometry of blade edge

Loading...

Loading...