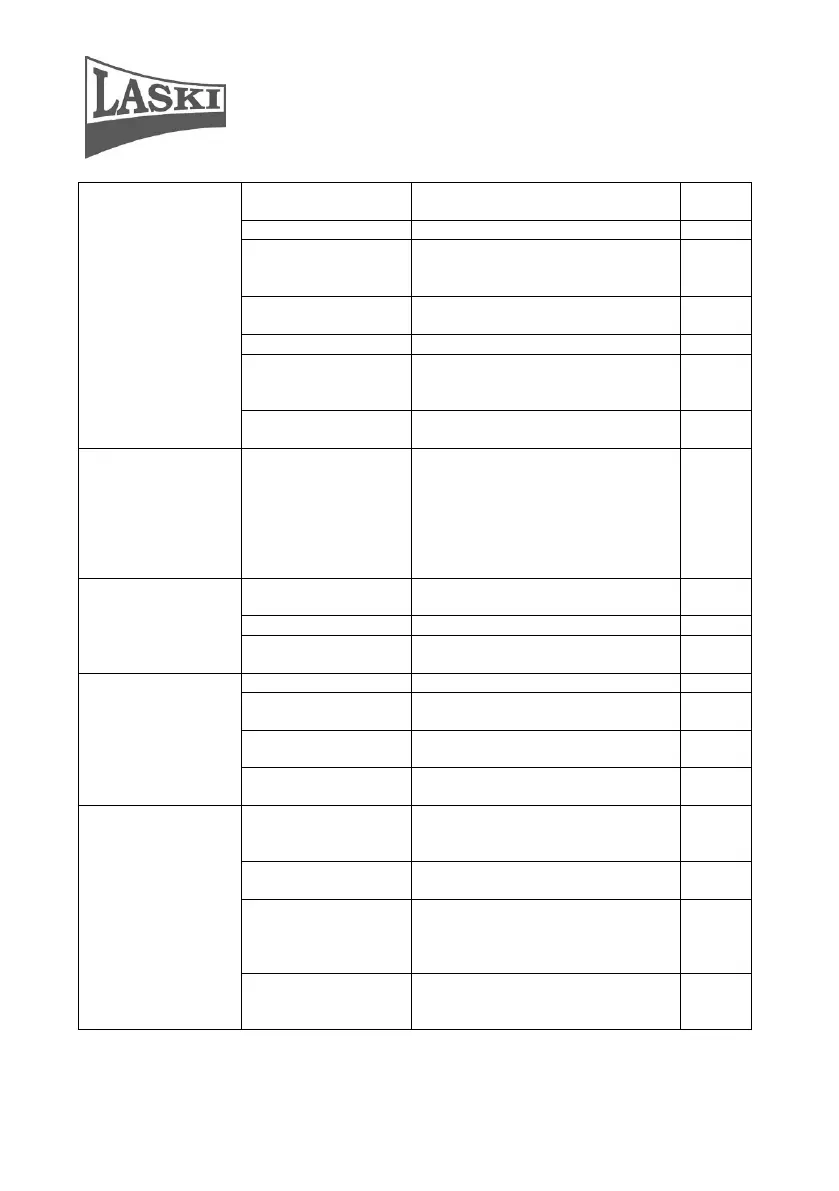

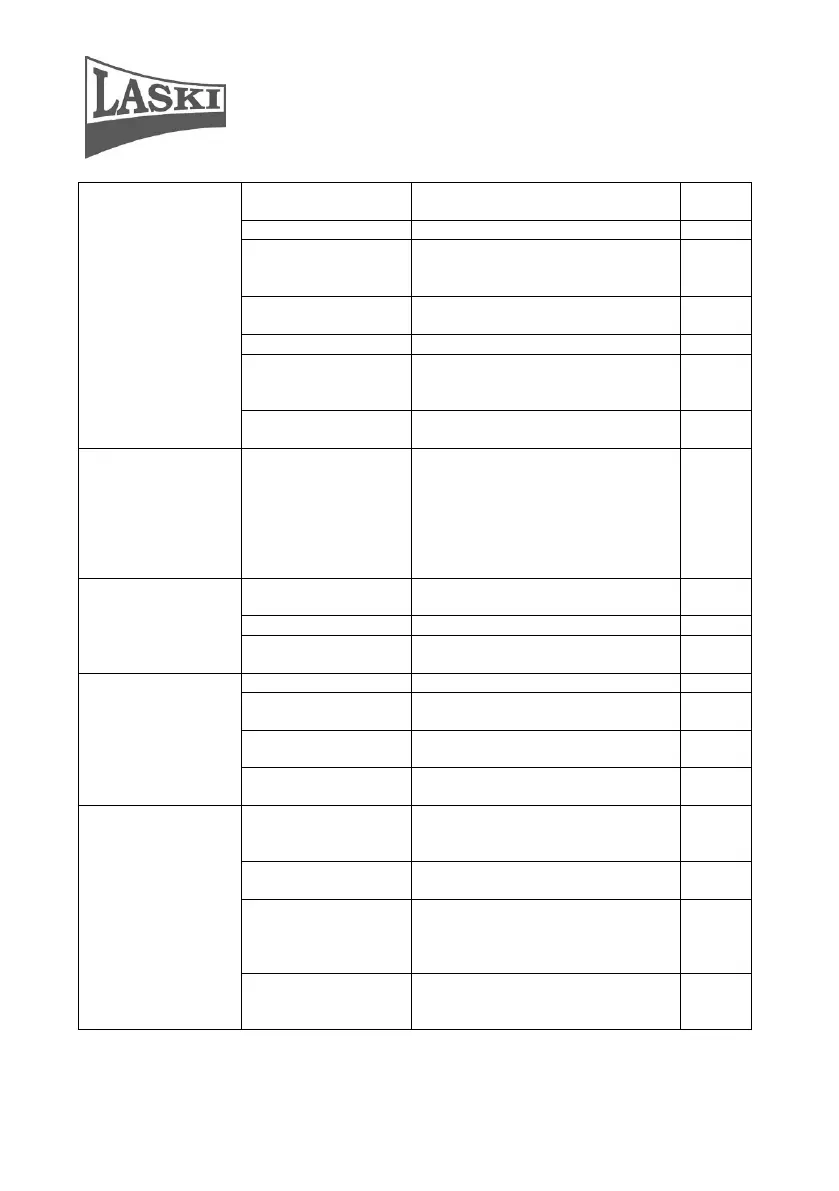

49

Check up manual speed regulation for

loading

Press the green button for loading

Failure of NOSTRESS

system

Measure voltage on coil of

electromagnetic valve; it should be 0

at max. speed

Faulty coil of

electromagnetic valve

Check up wiring for integrity

Check up oil pressure

Pump replacement

Faulty electric

switchboard

Loading rolls turn off

also while chipping

Loading rolls cannot

be set in motion again

after turning the

machine off

Excessive speed of

chipping wheel and

PTO shaft

Reduce the PTO shaft speed

Working speed of the chipping wheel

must not exceed 1500 rpm.

Blades touch opposite

edge

Wrong setting of

clearance

Set distance to 0,5 – 1 mm

Clearance of chipping

wheel bearings

Tighten up fixing bolt of wheel on its

shaft

NOSTRESS system

out

of function

Replacement of fuse 7,5 A

Faulty electronic

control unit

Replacement of fuse 4 A (inside

control unit)

Faulty speed sensor –

LED is not flashing

Loading chute gets

clogged

Discharge duct gets

clogged

Too low speed of PTO

shaft

Stop loading and increase speed at

chipping. Min. working speed of PTO

shaft at chipping is 350 rpm

Too small, dry or rotten

materials

Loading rolls

overloaded with

material

Reduce loading roll speed

Loading...

Loading...